High-temperature-resistant high-viscosity high-strength and high-toughness interlayer binding material and preparation method

A bonding material and high-temperature-resistant technology, applied in the field of interlayer bonding materials, high-temperature-resistant, high-viscosity, high-strength, high-toughness interlayer bonding materials and their preparation, can solve problems such as poor impact resistance and low toughness, and achieve bonding Excellent effect, improving poor impact resistance and improving road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a high-temperature-resistant, high-viscosity, high-strength, and high-toughness interlayer bonding material, which is made of the following raw materials in parts by weight: 15 parts of polytetrahydrofuran ether glycol (PTMG), isophorone diisocyanate ( IP-DI) 5 parts, succinic anhydride 5 parts, diethanolamine 5 parts, trimethylolpropane 4 parts, heterocyclic aramid fiber 35 parts, epoxy resin 100 parts, triethylenetetramine 12 parts.

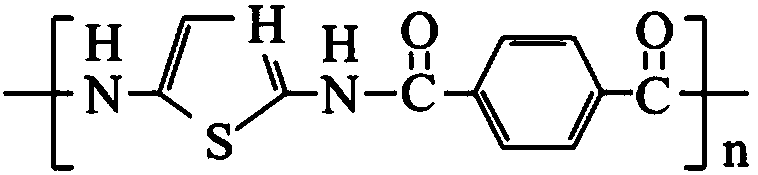

[0047] The heterocyclic aramid fiber in this example is a five-membered nitrogen-containing heterocyclic polyaramid, and its specific structural formula is:

[0048]

[0049] Wherein: n ranges from 100 to 1000. The heterocyclic aramid fiber is a five-membered nitrogen-containing heterocyclic polyarylamide synthesized by high-temperature solution polymerization whose starting monomers are 2,5-diaminothiazole and terephthalic acid. In organic solvents such as dimethyl sulfoxide and N,N-dimethylformamide, the me...

Embodiment 2

[0074] This embodiment provides a high-temperature-resistant, high-viscosity, high-strength, and high-toughness interlayer bonding material, which is made of the following raw materials: 18 parts of PTMG, 7 parts of IP-DI, 7 parts of succinic anhydride, 8 parts of diethanolamine, 5 parts of trimethylolpropane, 35 parts of heterocyclic aramid fiber, 100 parts of epoxy resin, and 12 parts of triethylenetetramine.

[0075] The selection and specification of raw material in the present embodiment are identical with embodiment 1.

[0076] The preparation method of the high-temperature-resistant, high-viscosity, high-strength and high-toughness interlayer adhesive material of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0078] This example provides a high-temperature-resistant, high-viscosity, high-strength, and high-toughness interlayer bonding material, which is made of the following raw materials in parts by weight: 20 parts of PTMG, 10 parts of IP-DI, 10 parts of succinic anhydride, and 10 parts of diethanolamine , 8 parts of trimethylolpropane, 35 parts of heterocyclic aramid fiber, 100 parts of epoxy resin, and 12 parts of triethylenetetramine.

[0079] The selection and specification of raw material in the present embodiment are identical with embodiment 1.

[0080] The preparation method of the high-temperature-resistant, high-viscosity, high-strength and high-toughness interlayer adhesive material of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com