Preparation method of standard digoxin substance

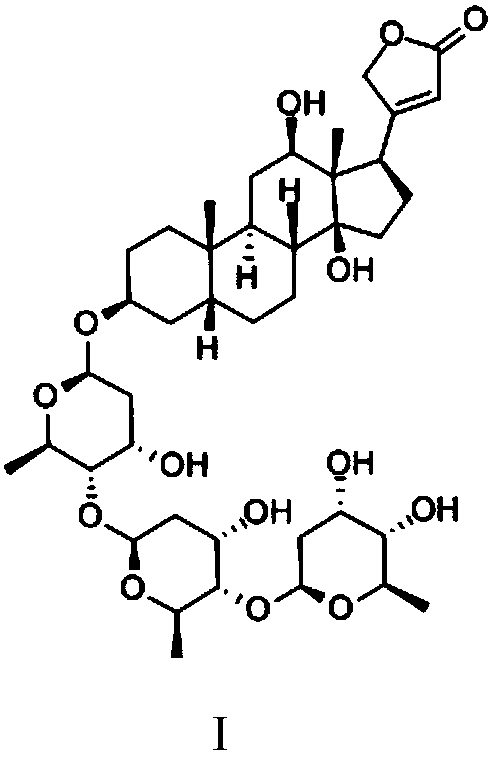

A standard substance and technology of digoxin, which is applied in the field of preparation of digoxin standard substances, can solve the problem of decreased impurity content, long delivery period, impurity digoxigenin and digoxin tetradigoxin saccharide. The problem of limited separation effect, etc., to achieve the effect of improving product purity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of digoxin standard substance, comprising the following steps:

[0036] (1) Weigh 2g of commercially available digoxin crude product (raw material) and add it to a 250ml round bottom flask, add 150mL of chloroform, install a reflux condenser, use an electric heating mantle to heat and boil to make all the solids dissolve, and then When the temperature of the solution drops to 55°C, add 0.1 g of activated carbon, then reflux at the boiling point for decolorization for 45 minutes, filter off the activated carbon with a heat preservation funnel, and rotate the obtained filter body to obtain 1.9 g of crude digoxin white crystals;

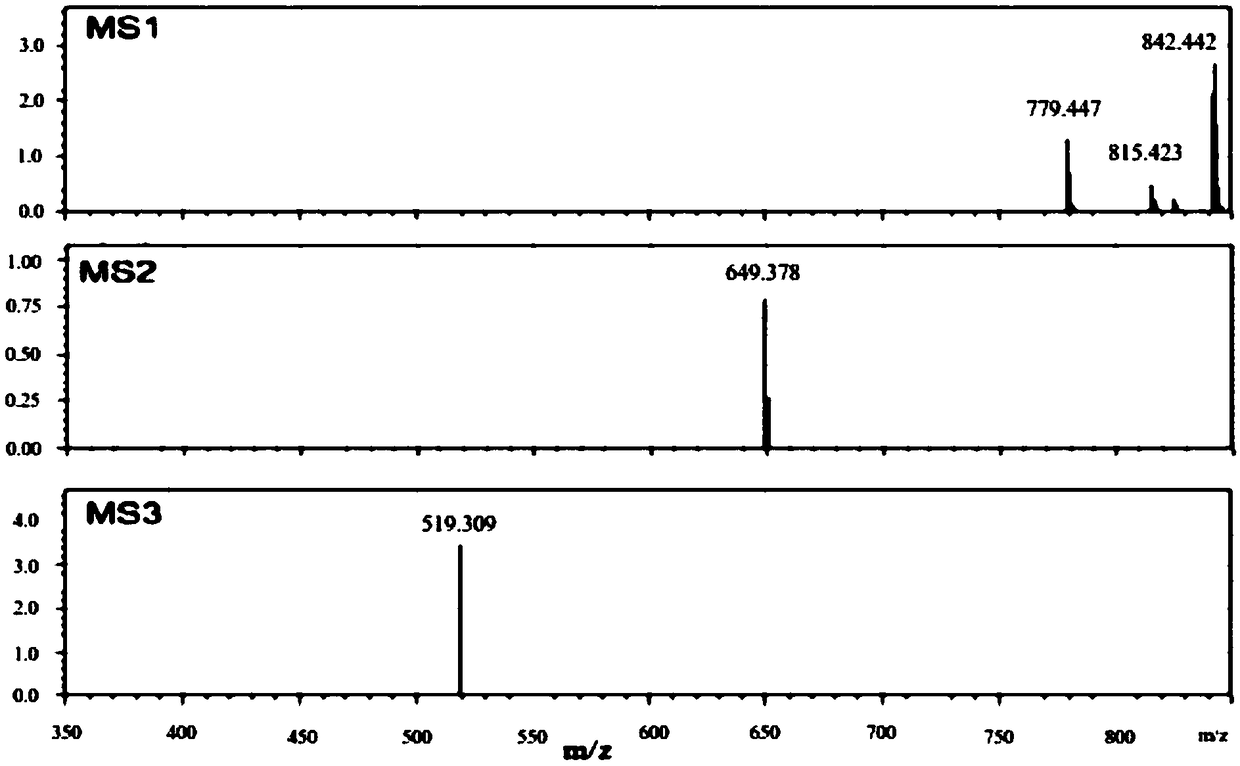

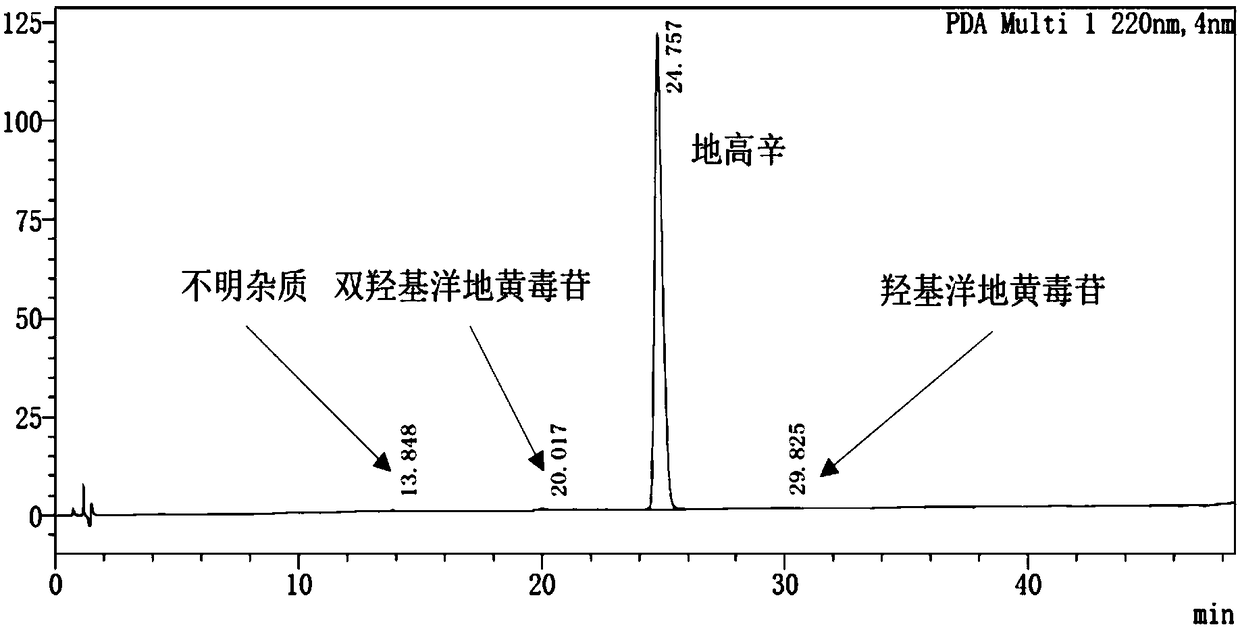

[0037] After detection by liquid chromatography, the content of digoxin was 97.9%, the content of dihydroxydigoxigenin was 1.0%, the content of digitalis was 0.3%, the content of hydroxydigoxigenin was 0.3%, and the content of digoxigenin was 0.3%. Other impurities are unknown components.

[0038](2) The 1.9g digoxin crystal...

Embodiment 2-6

[0055] The starting materials were 2 g of commercially available crude digoxin, and the preparation steps were the same as in Example 1, and the specific parameters were shown in Table 1.

[0056] Table 1

[0057]

[0058]

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com