Preparation method of triterpenic acid in jujube material

A technology of triterpene acids and jujube materials, which is applied in the field of preparation of triterpene acids in jujube materials, can solve the problems of low extraction rate and low separation purity of active ingredients, and achieve high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

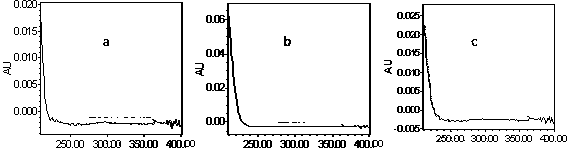

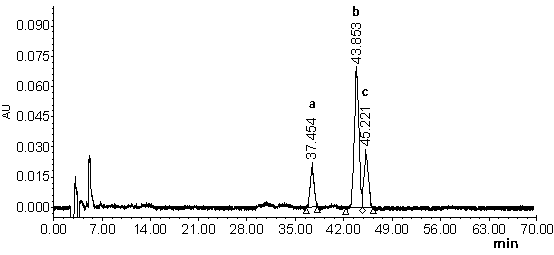

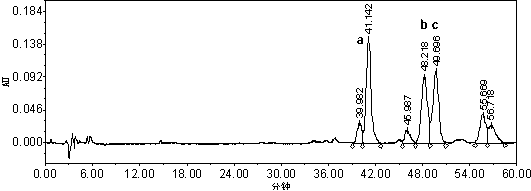

Image

Examples

Embodiment 1

[0034] Example 1 A preparation method of triterpene acids in jujube powder

[0035] The preparation method is carried out in the following order of steps:

[0036] (1) Preparation of jujube powder

[0037] The jujube fruit is pitted and crushed to obtain the jujube powder;

[0038] (2) Preparation of jujube crude extract

[0039] The jujube powder was extracted with 80% ethanol solution under reflux at 85°C, extracted twice for 2 hours each time, the extract was concentrated under reduced pressure, and the ethanol solution was recovered to obtain the crude jujube extract;

[0040] (3) Preparation of triterpene acid macroporous resin separation components

[0041] Jujube crude extract was separated by AB-8 macroporous adsorption resin column, the volume ratio of sample volume to separation material was 1:200, and the separation steps were as follows: first, wash with pure water until the separation column was colorless, and then use 2 column volumes of The 70% ethanol solut...

Embodiment 2

[0046] Example 2 A preparation method of triterpene acids in jujube dregs

[0047] The preparation method is carried out in the following order of steps:

[0048] (1) Preparation of jujube dregs

[0049] The jujube fruit is pitted and crushed to obtain jujube powder, and an extraction solvent is added. The weight volume ratio of the jujube powder to the extraction solvent is 1:10, and the extraction is carried out under heating and pressure. The extraction solvent is 15% ethanol aqueous solution, and the extraction temperature is 80°C. Extract for 20 min each time, repeat the extraction twice, and filter to obtain jujube dregs;

[0050] (2) Preparation of jujube crude extract

[0051] Jujube dregs were reflux extracted with absolute ethanol at 80°C, extracted twice for 90 min each time, the extract was concentrated under reduced pressure, and ethanol was recovered to obtain crude jujube extract;

[0052] (3) Preparation of triterpene acid macroporous resin separation compon...

Embodiment 3~8

[0058] The preparation method of triterpene acid in the jujube material of embodiment 3~8

[0059] Examples 3 to 8 are respectively a preparation method of triterpene acids in jujube material. The operation steps are the same as those in Example 1 and Example 2, except for the type and purity of the alcohol, and the reaction time and reaction time in the process. The temperature and other control parameters are different, see the table below for details:

[0060]

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com