5-methyol resorcinol diglycidyl ether and preparation method thereof

A technology of hydroxymethyl resorcinol and diglycidyl ether, which is applied in the field of glyceryl ether and its preparation, can solve problems such as poor bonding strength, and achieve the effects of mild reaction conditions, high yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

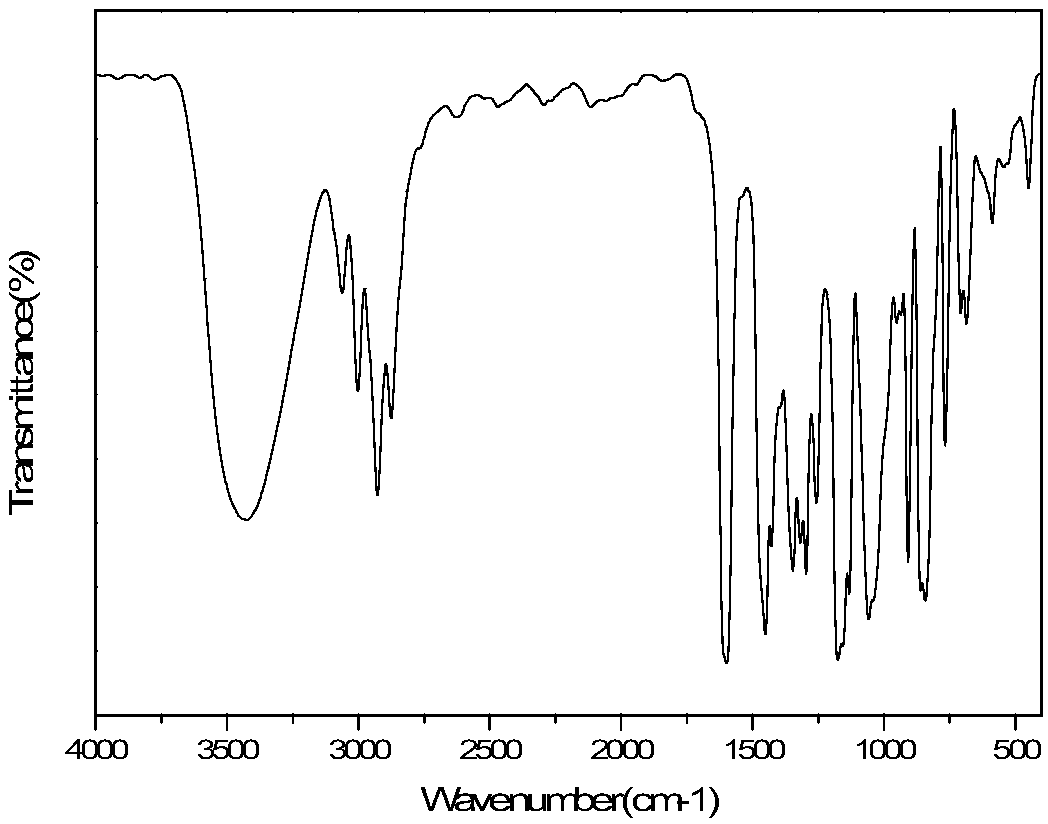

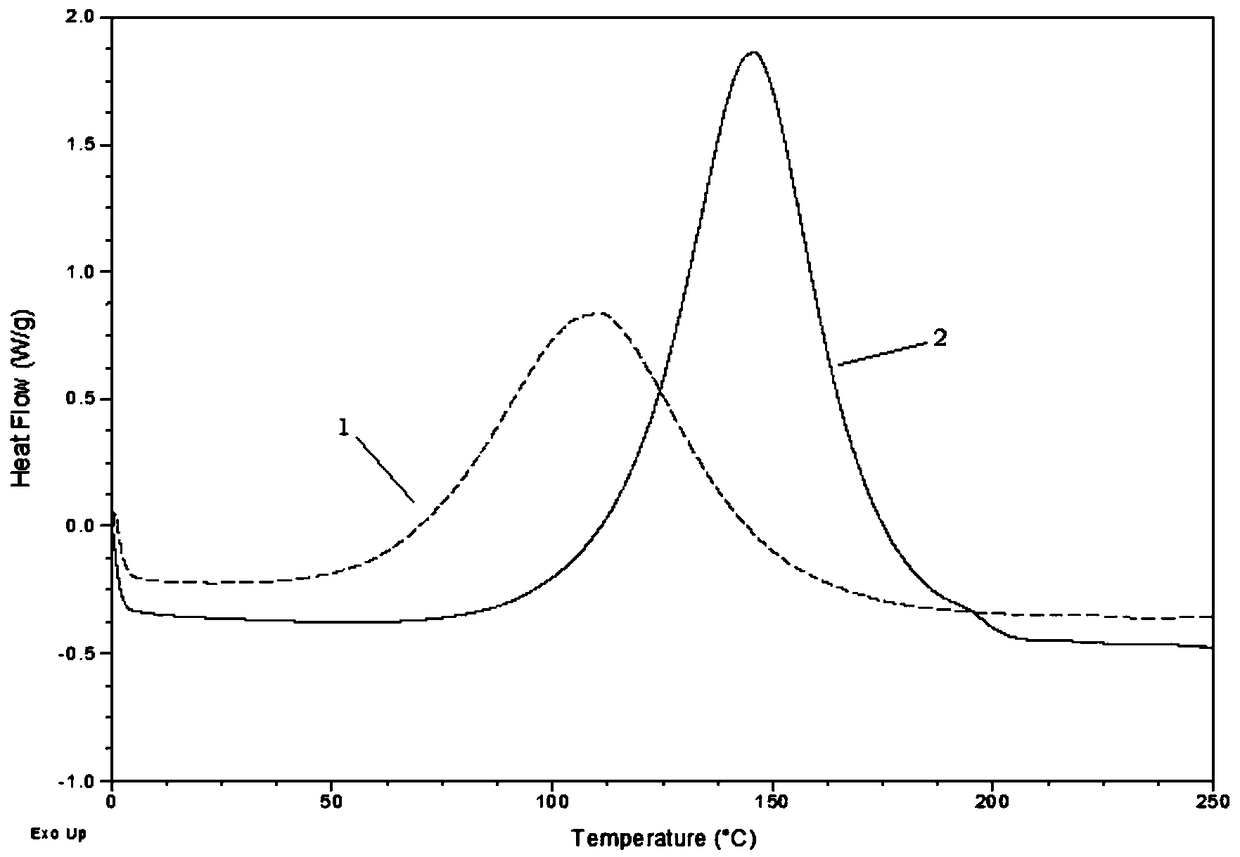

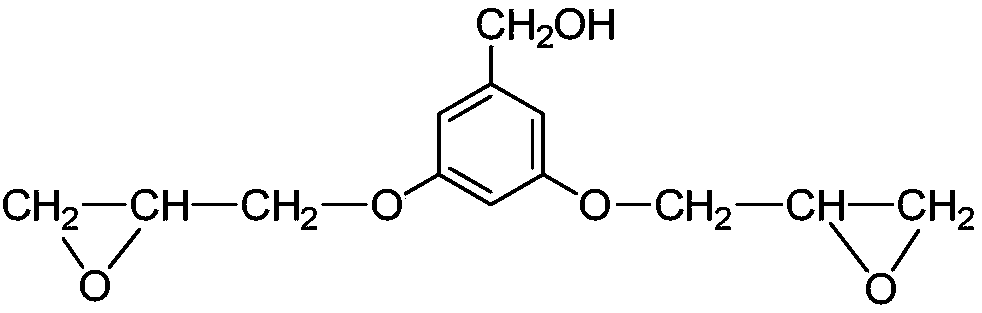

[0030] Specific embodiment one: the molecular structural formula of the present embodiment 5-hydroxymethyl resorcinol diglycidyl ether is:

[0031]

specific Embodiment approach 2

[0032] Specific embodiment two: the preparation method of 5-hydroxymethyl resorcinol diglycidyl ether comprises the following steps:

[0033] 1. Add 5-formyl resorcinol diglycidyl ether and organic solvent in a mass ratio of 1: (10~20) into a fully dry reaction kettle, and stir at a low temperature of -15°C~0°C for 0.5h~ 2h, and nitrogen protection;

[0034] 2. Add catalyst solid powder in batches, add once every 30min, and add in 4 times in total; after adding, continue to react at -15℃~0℃ for 2h~8h, then raise the temperature to 25℃~50℃ for 0.5h~ 4h; wherein the number of moles of catalyst solid powder is 1.1 to 1.5 times the number of moles of 5-formyl resorcinol diglycidyl ether;

[0035] 3. After the reaction, add water and stir for 30-40 minutes, add toluene to extract and separate the organic phase, and distill under reduced pressure to remove the organic solvent, then recycle and reuse to obtain 5-hydroxymethyl resorcinol diglycidyl ether.

specific Embodiment approach 3

[0036] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the preparation method of 5-formyl resorcinol diglycidyl ether in step one, specifically:

[0037] 1. Put 3,5-dihydroxybenzaldehyde, epibromohydrin and catalyst into the reaction kettle, raise the temperature to 80℃~100℃, stir for 2h~8h, then raise the temperature to the reflux temperature to remove the excess epoxybromopropane Evaporate under reduced pressure, recover and recycle to obtain a concentrated solution; wherein the molar ratio of 3,5-dihydroxybenzaldehyde and epibromohydrin is 1: (6-20), the ratio of 3,5-dihydroxybenzaldehyde and catalyst The mass ratio is 100: (0.1~5);

[0038] 2. After the temperature of the concentrated solution is cooled to 40°C to 60°C, add organic solvent and metal alkali solid particles, and continue to stir for 2h to 6h; wherein the mass ratio of 3,5-dihydroxybenzaldehyde to organic solvent is 1:(10 ~25), the molar ratio of 3,5-dihydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Loss modulus | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com