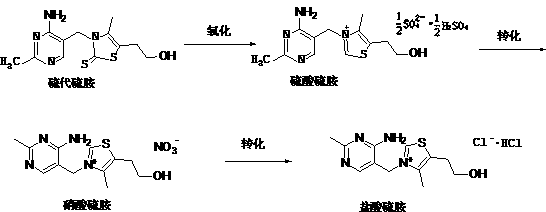

Method for preparing fursultiamine

A technology of furathiamine and tetrahydrofuryl methyl sodium thiosulfate, which is applied in the field of preparation of furathiamine, can solve the problems of abnormal production and high cost, and achieve the effects of reduced production cost, low cost, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

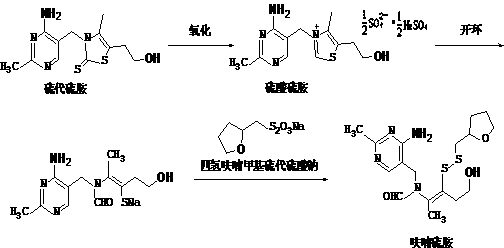

Method used

Image

Examples

Embodiment 1

[0019] In a 500ml three-necked flask with stirring, add 100g of thiothiamine (pure) and 150g of pure water, stir to cool down, and when the temperature drops to 15°C, slowly add 114.72g of hydrogen peroxide aqueous solution with a mass percentage concentration of 25%. , control the reaction temperature to 15℃-30℃, add dropwise for 5 hours, keep the temperature for 0.5h after the reaction, add 5g of activated carbon, decolorize for 1h, filter, filter out the activated carbon, put the obtained filtrate into a 1000 ml three-necked flask with stirring , stirring to cool down, controlling 20 ℃-30 ℃, adding 80g 25% sodium hydroxide aqueous solution dropwise, adjusting the pH of the solution system to 11-12, the dropping time was 2 hours, the dropwise addition was completed, the temperature was kept stirring for 0.5 hours, and then 80 g tetrahydrofuran methyl group was added. Sodium thiosulfate, controlled at 20°C-30°C, kept stirring for 4 hours, filtered to obtain the crude furanthia...

Embodiment 2

[0021] In a 500ml three-necked flask with stirring, add 100g of thiothiamine (pure) and 150g of pure water, stir to cool down, and when the temperature drops to 15°C, add 95.60g of hydrogen peroxide aqueous solution with a concentration of 30% by mass dropwise , control the reaction temperature to 15℃-30℃, add dropwise for 4 hours, keep the temperature for 0.5h after the reaction, add 5g activated carbon, decolorize for 1h, filter, filter out the activated carbon, put the obtained filtrate into a 1000 ml three-necked flask with stirring , stirring and cooling, controlling 20 ℃-30 ℃, adding 112g 25% potassium hydroxide aqueous solution dropwise, adjusting the pH of the solution system to 11-12, the dropping time was 2 hours, the dropping was completed, and the temperature was kept stirring for 0.5 hours, and then 80g tetrahydrofuran methyl sulfide was added. Substitute sodium sulfate at 20°C-30°C, keep stirring for 4 hours, filter to obtain the crude furanthiamine, recrystallize...

Embodiment 3

[0023] In a 500ml three-necked flask with stirring, add 100g of thiothiamine (pure) and 150g of pure water, stir to cool down, and when the temperature drops to 15°C, dropwise add 104.30g of an aqueous hydrogen peroxide solution with a concentration of 27.5% by mass, Control the reaction temperature to 15℃-30℃, add the reaction dropwise for 6 hours, keep the temperature for 0.5h after the reaction, add 5g of activated carbon, decolorize for 1h, filter, filter out the activated carbon, put the obtained filtrate into a 1000 ml three-necked flask with stirring, Stir and cool down, control 20℃-30℃, add 67g of 30% sodium hydroxide aqueous solution dropwise, adjust the pH of the solution system to 11-12, add dropwise for 2 hours, end the dropwise addition, keep stirring for 1 hour, then add 80g of tetrahydrofuran methylthio Sodium sulfate, controlled at 20°C-30°C, kept stirring for 4 hours, filtered to obtain the crude furanthiamine, recrystallized with water, filtered, and dried to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com