Preparation method of porous cobaltosic oxide nanosheet

A technology of cobalt trioxide nanometer and cobalt salt, which is applied in the direction of cobalt oxide/cobalt hydroxide and nanotechnology, which can solve the problems of complex synthesis process and limitation of large-scale application of cobalt tetraoxide nanosheets, and meet the requirements of simple equipment, shortened transmission distance, and raw materials Effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

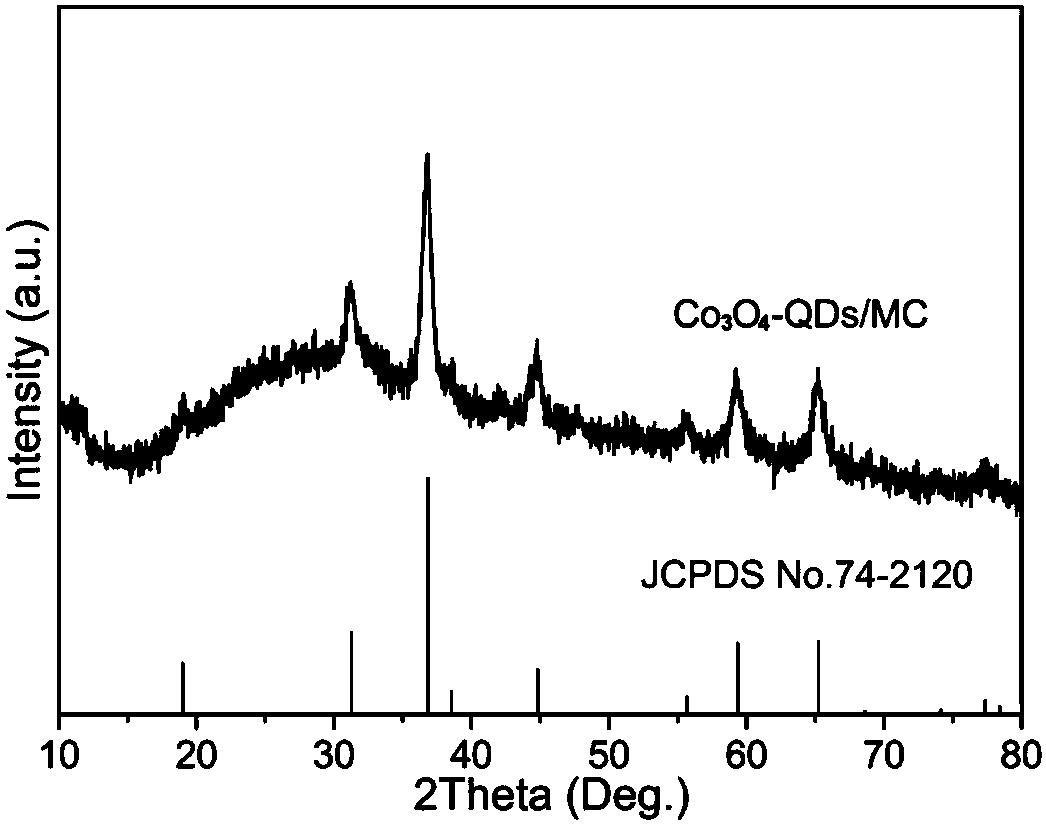

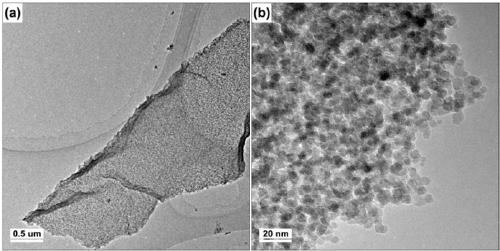

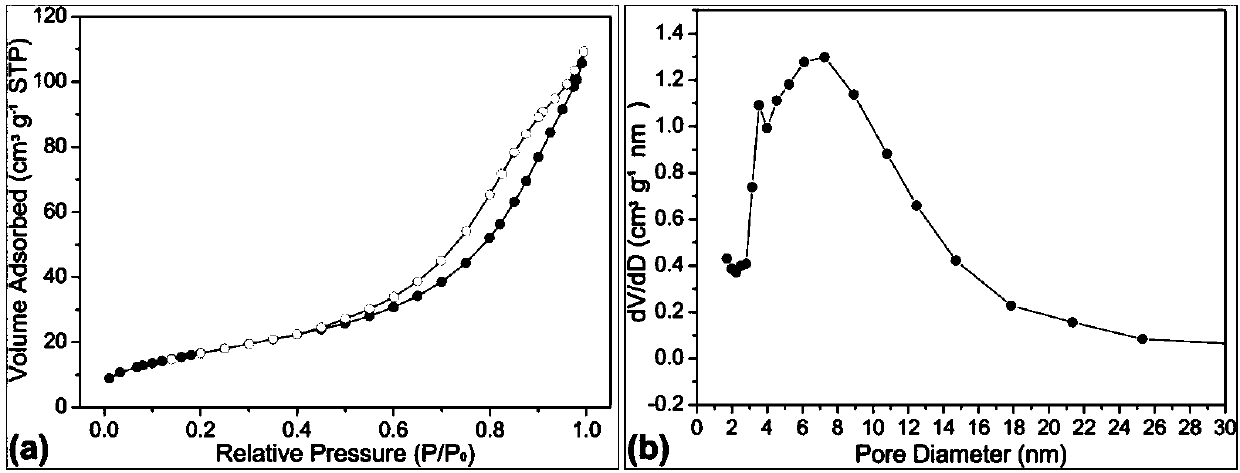

[0044] Take corn stalks and peel off the outer skin, and crush the inner pulp into small particles. Take 1g of crushed corn stalk particles, treat with 200mL of 1.5% dilute sulfuric acid, heat in an oil bath to 95°C, stir for 1h, wash until neutral, filter, blow dry at 40°C for 24h, and set aside. Weigh 0.996 g of cobalt acetate tetrahydrate, add 35 mL of distilled water, and 5 mL of ethanol to prepare a 100 mmol / L cobalt acetate solution. Weigh 0.2 g of acid-treated corn stalk particles into a 100 mL round-bottomed flask, add 40 mL of prepared cobalt acetate solution, sonicate at room temperature for 30 min, vacuum at -0.09 MPa for 30 min, and then sonicate again for 30 min. Suction filtration and drying at 60°C for 12h. The dried corn stalk particles were roasted in a tube furnace under an argon atmosphere, the heating rate was 5°C / min, the roasting temperature was 600°C, and the roasting time was 4h. After cooling, grind to obtain metal cobalt nanocrystal / mesoporous carbo...

Embodiment 2

[0051] Take corn stalks and peel off the outer skin, and crush the inner pulp into small particles. Take 1g of crushed corn stalk particles, treat with 200mL of 1.5% dilute sulfuric acid, heat in an oil bath to 95°C, stir for 1h, wash until neutral, filter, blow dry at 40°C for 24h, and set aside. Weigh 0.996 g of cobalt acetate tetrahydrate, add 35 mL of distilled water, and 5 mL of ethanol to prepare a 100 mmol / L cobalt acetate solution. Weigh 0.2 g of acid-treated corn stalk particles into a 100 mL round-bottomed flask, add 40 mL of prepared cobalt acetate solution, sonicate at room temperature for 30 min, vacuum at -0.09 MPa for 30 min, and then sonicate again for 30 min. Suction filtration and drying at 60°C for 12h. The dried corn stalk particles were roasted in a tube furnace under an argon atmosphere, the heating rate was 5°C / min, the roasting temperature was 600°C, and the roasting time was 4h. After cooling, grind to obtain metal cobalt nanocrystal / mesoporous carbo...

Embodiment 3

[0054] Take corn stalks and peel off the outer skin, and crush the inner pulp into small particles. Take 1g of crushed corn stalk particles, treat with 200mL of 1.5% dilute sulfuric acid, heat in an oil bath to 95°C, stir for 1h, wash until neutral, filter, blow dry at 40°C for 24h, and set aside. Weigh 0.996 g of cobalt acetate tetrahydrate, add 35 mL of distilled water, and 5 mL of ethanol to prepare a 100 mmol / L cobalt acetate solution. Weigh 0.2 g of acid-treated corn stalk particles into a 100 mL round-bottomed flask, add 40 mL of prepared cobalt acetate solution, sonicate at room temperature for 30 min, vacuum at -0.09 MPa for 30 min, and then sonicate again for 30 min. Suction filtration and drying at 60°C for 12h. The dried corn stalk particles were roasted in a tube furnace under an argon atmosphere, the heating rate was 5°C / min, the roasting temperature was 600°C, and the roasting time was 4h. After cooling, grind to obtain metal cobalt nanocrystal / mesoporous carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com