Self-cleaning type coal-to-gas boiler

A coal-to-gas and boiler technology, which is used in gas treatment, non-flammable liquid/gas transportation, combustion methods, etc., can solve the problem of changing people's lifestyles, increasing use costs, and the ratio of combustion interface and circulating air volume cannot be reasonably adjusted, etc. problem, to achieve the effect of multiple utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

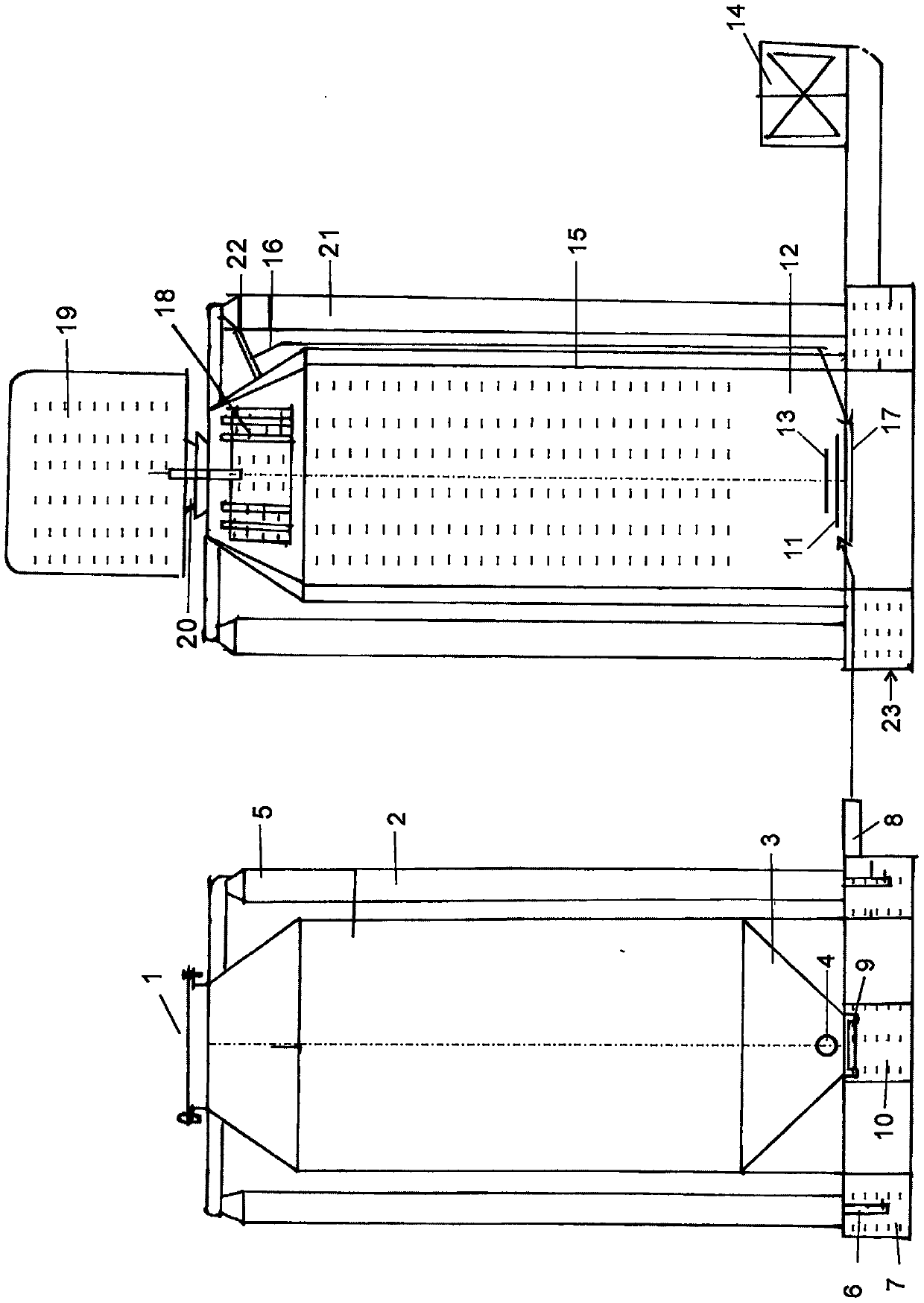

[0006] According to one embodiment of the present invention, the gasification device is a device for producing gas through oxygen-controlled combustion, which is composed of a gasification chamber, a combustion chamber, a reciprocating grate, an air supply channel, an air filter cartridge, and a water bath air bag. . In this device, the fuel is accumulated in the gasification chamber, and is combusted through the bottom combustion chamber under the condition of controlled air circulation, and the coke residue is removed under the agitation of the reciprocating grate, and the air is sent through the supplementary air channel according to the oxygen demand of the combustion. , the fuel is burned to produce carbon monoxide through controlled oxygen, and the carbon monoxide gas along with the flue gas passes through the branch filter cartridge at the top branch after preliminary filtration, and then enters the water bath air bag through the bubbling tube, and the gas enters the sel...

Embodiment

[0031] The fuel is fed into the gasification chamber from the top of the gasifier by intermittent feeding method and the top cover is closed (Figure 1), so that the fuel is accumulated in the gasification chamber (Figure 2). Since the top cover is closed, the gasification chamber and The outside air is isolated, and the gasifier is ignited through the bottom combustion chamber (Figure 3) under the condition of controlled air circulation, and the combustion layer in the combustion chamber is quantitatively sent into Air. Because the amount of oxygen intervention is controlled, the combustion state is low-oxygen smoldering. Under this condition, the flue gas generated by fuel combustion is coal gas with carbon monoxide as the main component. The coal gas goes up under the impetus of its own heat, transfers heat and preheats the material layer while passing through the material layer, and then enters the branch filters at the top branch (Figure 5), and passes through the prelimin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com