Aluminum oxide carrier, preparation method of catalyst containing aluminum oxide carrier, and application of catalyst

An alumina carrier and catalyst technology, applied in the field of chemistry, can solve the problems of low catalyst stability, frequent regeneration, deactivation of carbon deposits, etc., so as to improve the conversion rate of alkane dehydrogenation and olefin selectivity, and improve the activity and stability. , the effect of strong charcoal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

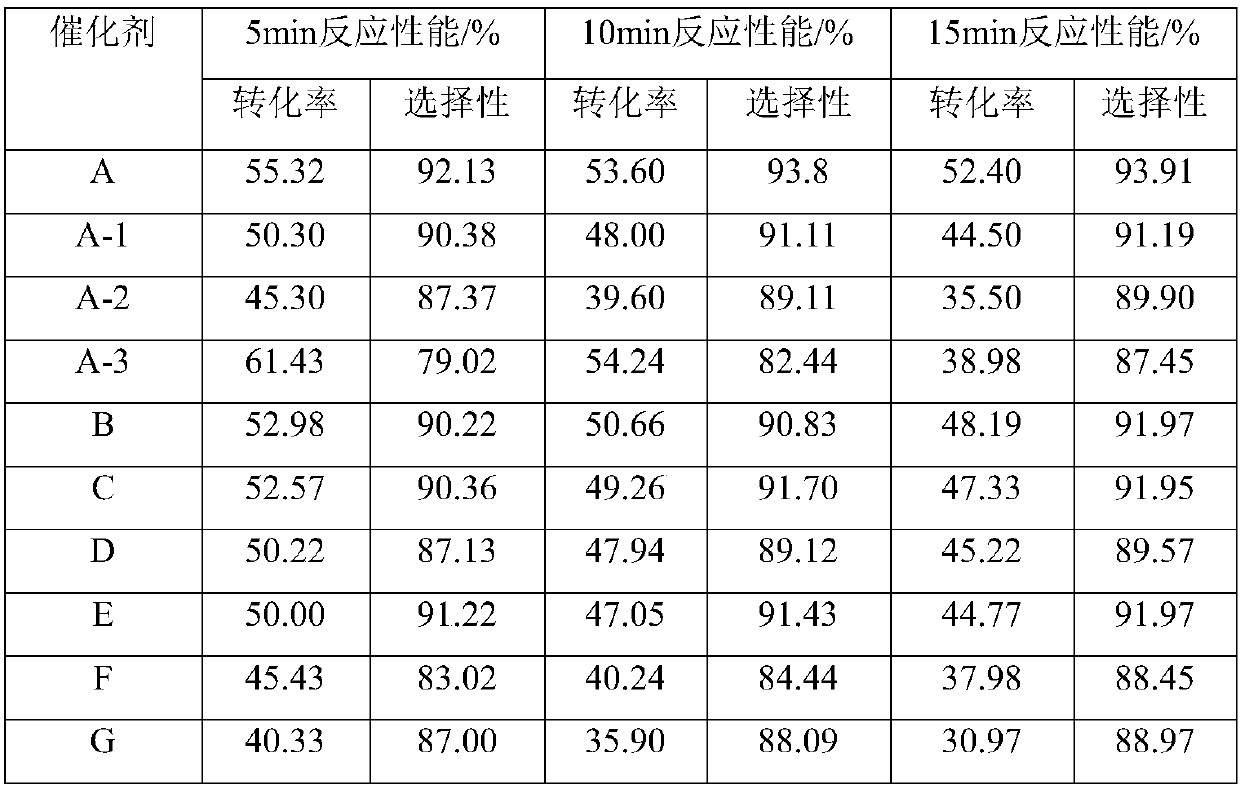

Embodiment 1

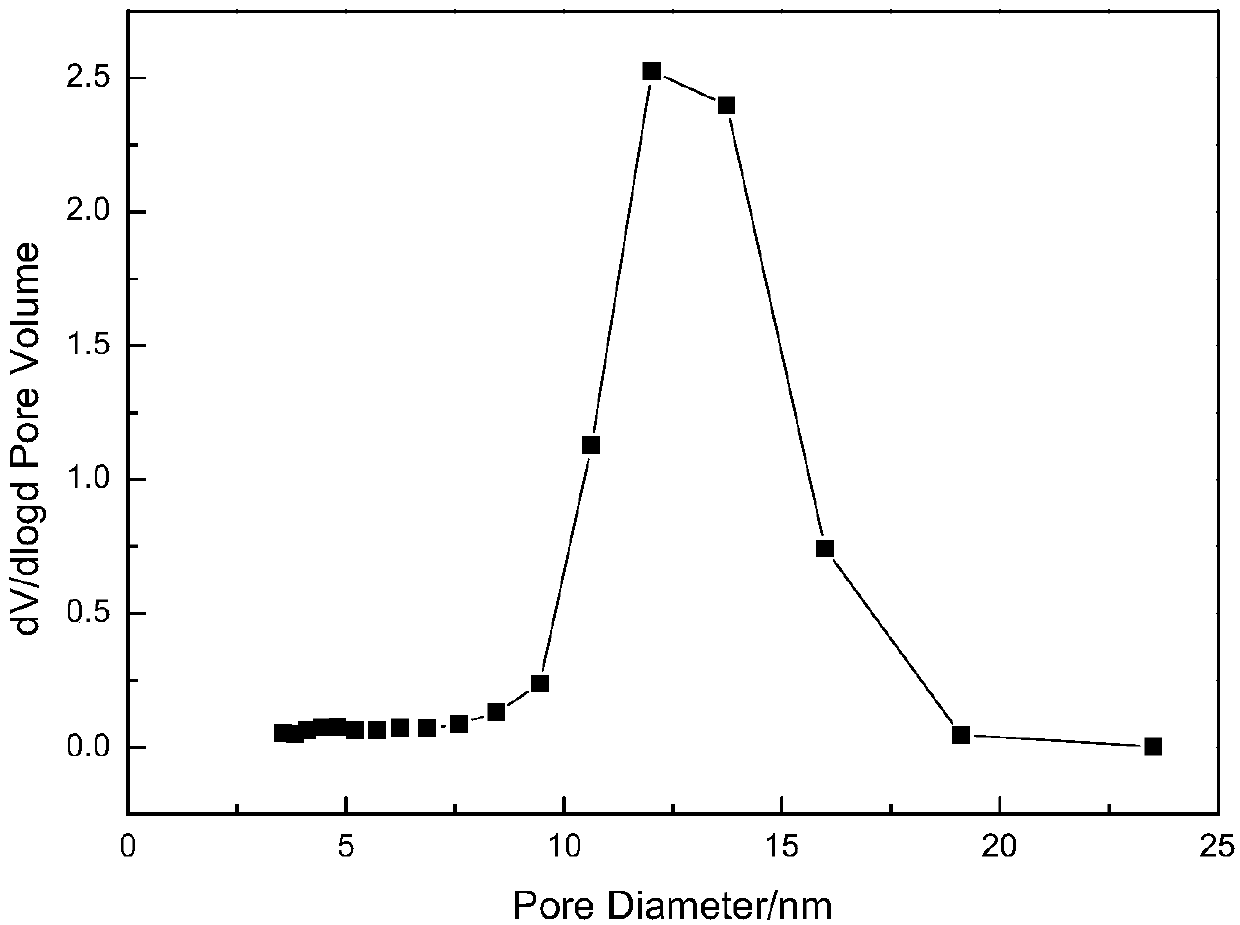

[0032] Carrier preparation: Take 60 grams of pseudoboehmite, 6 grams of methylcellulose, 4 grams of starch, 4 grams of hexamethylenetetramine, and 6 grams of urea, add an appropriate amount of deionized water and stir to form alumina with a mass content of 25%. Continue stirring for 2 hours, slowly add 21.5 g of nitric acid solution with a mass concentration of 25%, and stir at 35° C. for 2 hours to form an alumina sol slurry. Drop the alumina sol into a hot oil column with liquid paraffin as the oil phase and an oil bath temperature of 85°C for molding, collect the formed pellets under the oil column, transfer them to an aging kettle for aging at 120°C for 12 hours, then wash with water, and dry at 130°C for 8 hours . Place the dried molded carrier in a high-temperature furnace, raise the temperature to 1000°C at a rate of 1.5°C / min and keep the temperature constant for 8 hours. 4h. The prepared alumina carrier is θ- and δ-mixed crystal form, with a specific surface area of...

Embodiment 2

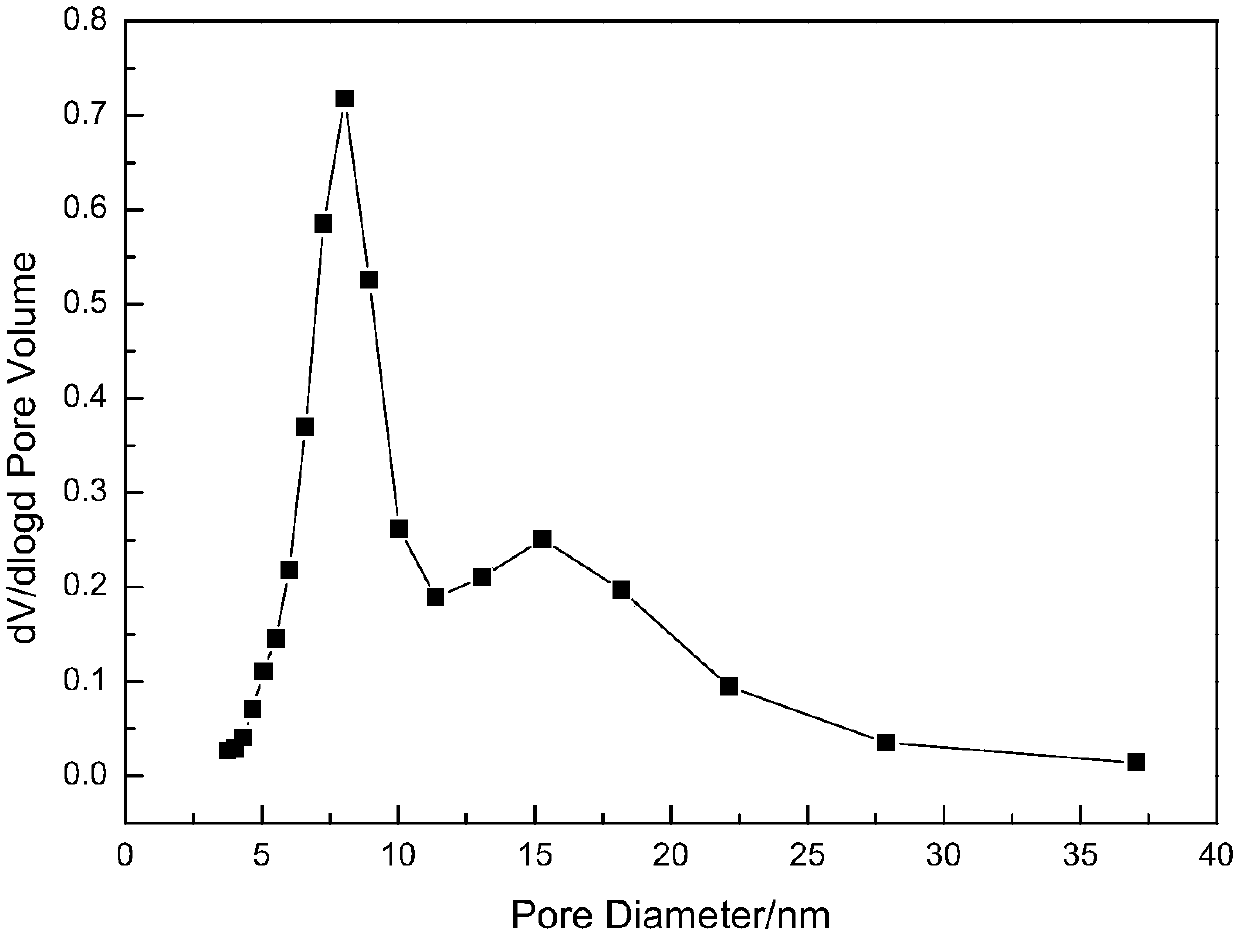

[0044] Carrier preparation: Take 70 grams of pseudoboehmite, 5 grams of polyacrylamide, 5 grams of methylcellulose, and 10 grams of urea, add an appropriate amount of deionized water and stir to form a suspension with a mass content of alumina of 35%, and continue Stir for 2 hours, slowly add 10 g of nitric acid solution with a mass concentration of 35%, and stir for 2 hours at 50° C. to form an alumina sol slurry. Add 30 grams of boehmite and 10 grams of gibbsite into the alumina sol, mix well, add 10 grams of scallop powder, 2 grams of 35% nitric acid, mix and knead, extrude into strips, and dry at 130°C for 8 hours. Place the dried molded carrier in a high-temperature furnace, raise the temperature to 1050°C at a rate of 2°C / min and keep the temperature constant for 4 hours. 6h. The prepared alumina support is θ- and δ-mixed crystal form, with a specific surface area of 125m 2 / g, the pore volume is 0.65ml / g, the average pore diameter is 34nm, and the ratio of pores wit...

Embodiment 3

[0047] Preparation of the carrier: the preparation of the carrier is the same as in Example 1, except that transformer oil is used as the oil phase.

[0048] Catalyst preparation: Weigh 0.29 g of potassium hydroxide and 1.48 g of potassium nitrate, add 40 ml of deionized water to make an impregnation solution, then weigh 45 g of the above-mentioned alumina carrier for equal volume impregnation, age at room temperature for 2 h, dry at 120 ° C for 4 h, and 600 The catalyst precursor containing potassium was obtained by calcining for 6 h under an air atmosphere at ℃. Weigh 19 grams of chromium nitrate and 10 grams of chromium trioxide, add 13ml of deionized water to make an impregnation solution to impregnate the catalyst precursor containing potassium, age at room temperature for 2 hours, dry at 120°C for 4 hours, and roast at 600°C for 6 hours in an air atmosphere to obtain the finished catalyst c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com