Composite electrode material and preparation method and application thereof

A composite electrode and composite material technology, applied in the direction of electrodes, nanotechnology for materials and surface science, battery electrodes, etc., can solve the problems of poor intrinsic activity, reduce pollution and danger, and make the synthesis process green and The effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] N-GCNTs / Fe 3 The preparation method of Ni nanocomposite material comprises the following steps:

[0046] (1) Mix and dissolve 0.145g nickel nitrate hexahydrate, 0.606g ferric nitrate nonahydrate, 4g melamine and 0.05g glucose in 20mL distilled water, stir for 60min, so that the three substances are evenly mixed; after evaporating and drying at 40°C, carry out Grinding to obtain a composite precursor;

[0047] (2) Put the obtained precursor in a tube furnace and calcinate in a nitrogen atmosphere at 500°C for 120min with a heating time of 500min; continue to heat up to 800°C for 120min with a heating time of 150min.

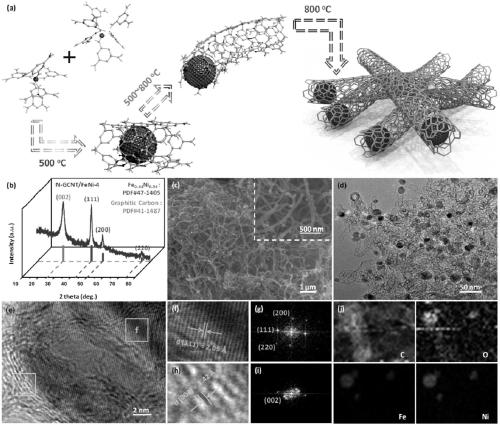

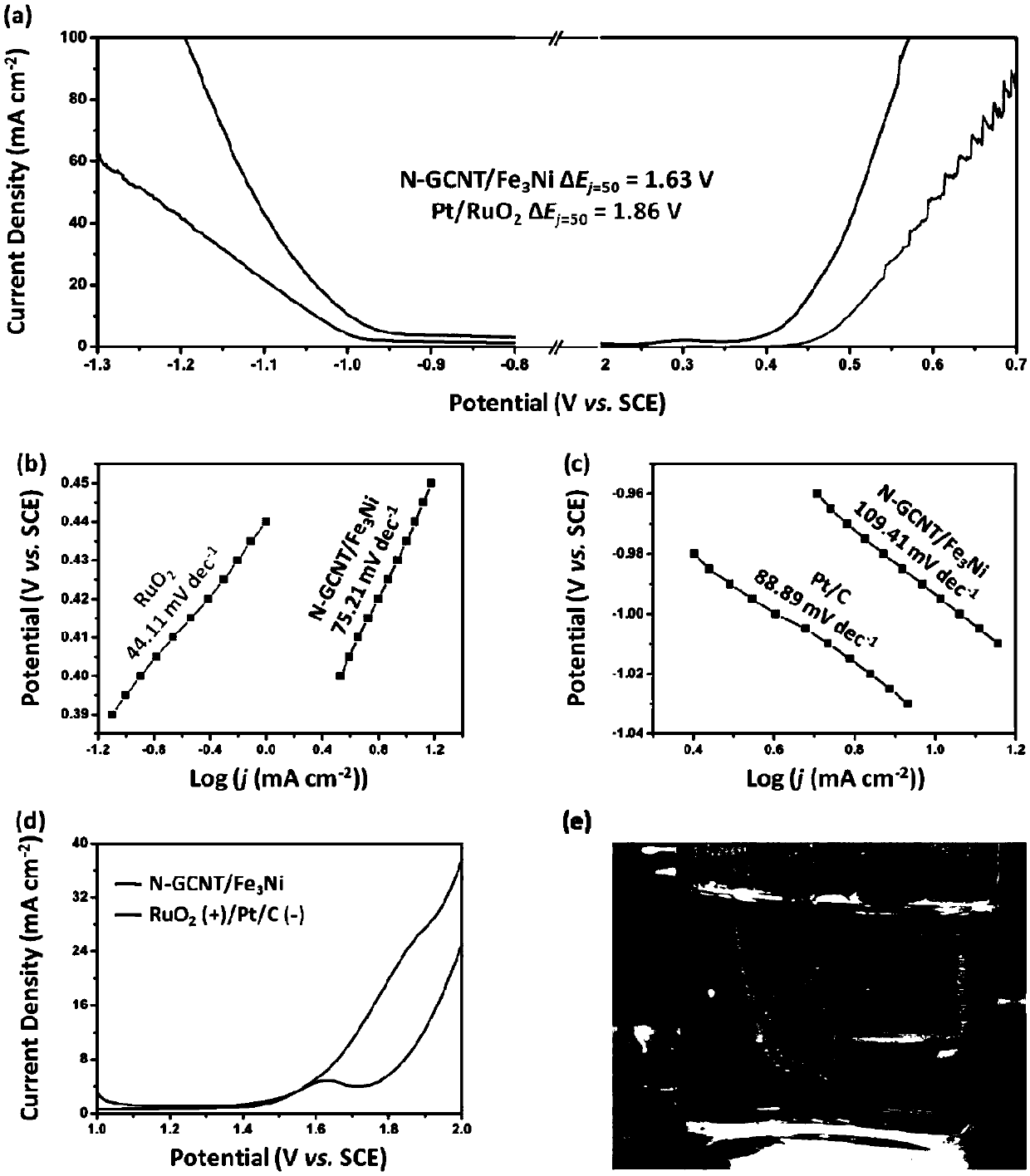

[0048] Through research, we synthesized the steps and mechanism of this method ( figure 1 a) is described as: first coordinate metal ions by organic carbon sources and nitrogen sources, and then calcine at 500°C to form C 3 N 4 / metal particle intermediate, further calcined at 800 °C, N-GCNTs / Fe catalyzed by metal nanoparticles can be obtained 3 Ni. ...

Embodiment 2

[0054] N-GCNTs / Fe 2 The preparation method of Ni nanocomposite material comprises the following steps:

[0055] (1) Mix and dissolve 0.193g nickel nitrate hexahydrate, 0.539g ferric nitrate nonahydrate, 4g melamine and 0.05g glucose in 20mL of distilled water, stir for 60min, so that the three substances are mixed evenly; grind after evaporating and drying at 40°C , to obtain the composite precursor.

[0056] (2) Put the obtained precursor in a tube furnace and calcinate in a nitrogen atmosphere at 500°C for 120min with a heating time of 500min; continue to heat up to 800°C for 120min with a heating time of 150min.

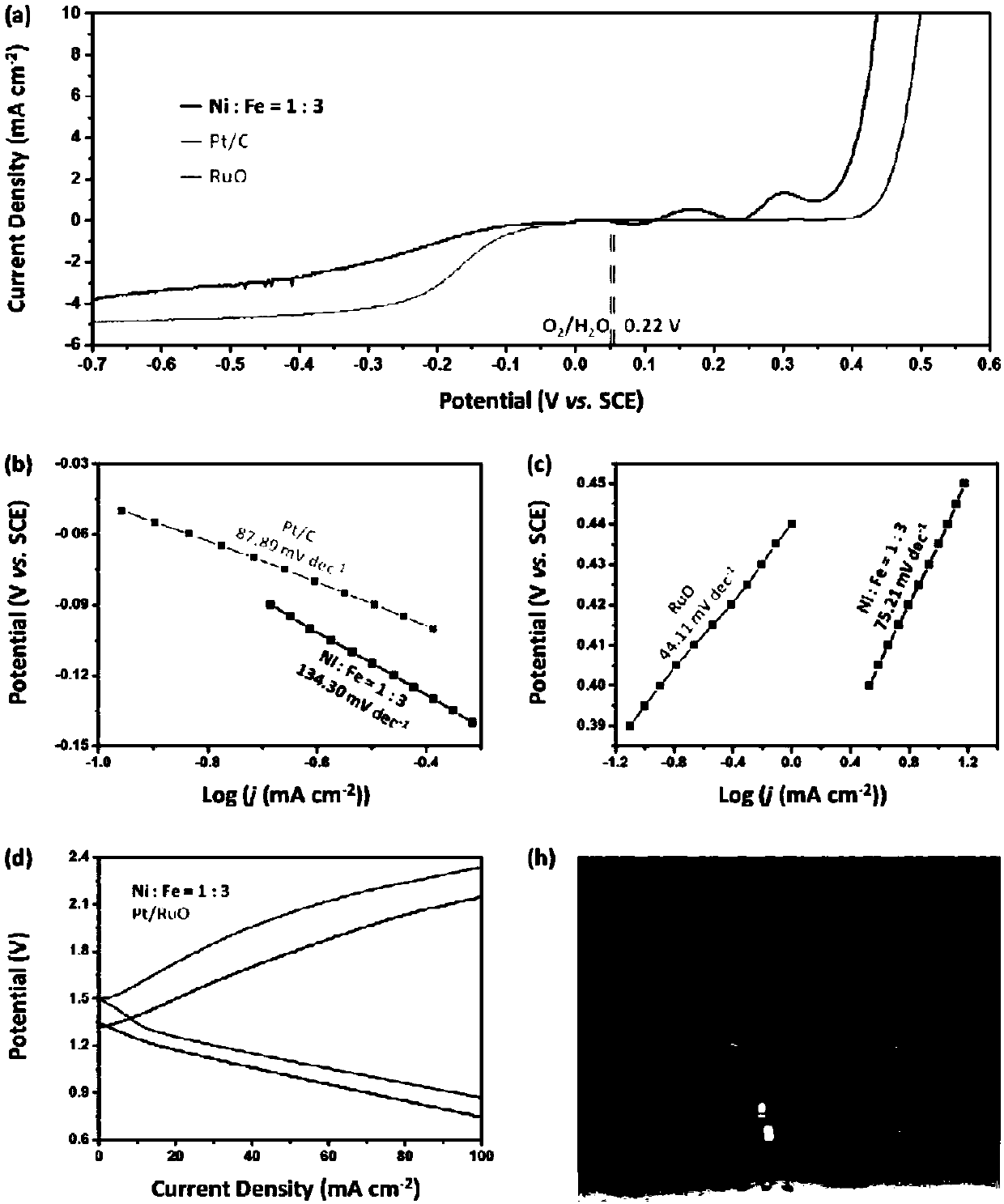

[0057] From the XRD pattern ( Figure 5 ), it can be seen that N-GCNTs / Fe 2 The crystal form of Ni is compared with the N-GCNTs / Fe of embodiment 1 3 Ni is similar, indicating that its structure is similar. SEM( Figure 7 ) shows that its morphology is similar to that of N-GCNTs / Fe 3 Ni approximation, but significant agglomeration also occurs. It can be see...

Embodiment 3

[0059] The preparation method of N-GCNTs / FeNi nano composite material comprises the following steps:

[0060] (1) Mix and dissolve 0.290 g of nickel nitrate hexahydrate, 0.404 g of ferric nitrate nonahydrate, 4 g of melamine and 0.05 g of glucose in 20 mL of distilled water, and stir for 60 min to make the three substances evenly mixed. After evaporating and drying at 40 °C, grinding was carried out to obtain the composite precursor.

[0061] (2) Put the obtained precursor in a tube furnace and calcinate in a nitrogen atmosphere at 500°C for 120min with a heating time of 500min; continue to heat up to 800°C for 120min with a heating time of 150min.

[0062] From the XRD pattern ( Figure 5 ), it can be seen that the crystal form of N-GCNTs / FeNi is better than that of N-GCNTs / FeNi in Example 1 3 Ni is less Fe 2 The peaks of C and elemental Fe indicate that its structure can be regulated by changing the composition. while SEM( Figure 8 ) shows that its general morphology i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com