Method for preparing graphene by using magnetic rotating arc

A technology of magnetic rotation and graphene, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of undiscovered graphene, etc., and achieve the effect of good crystal form, simple equipment and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

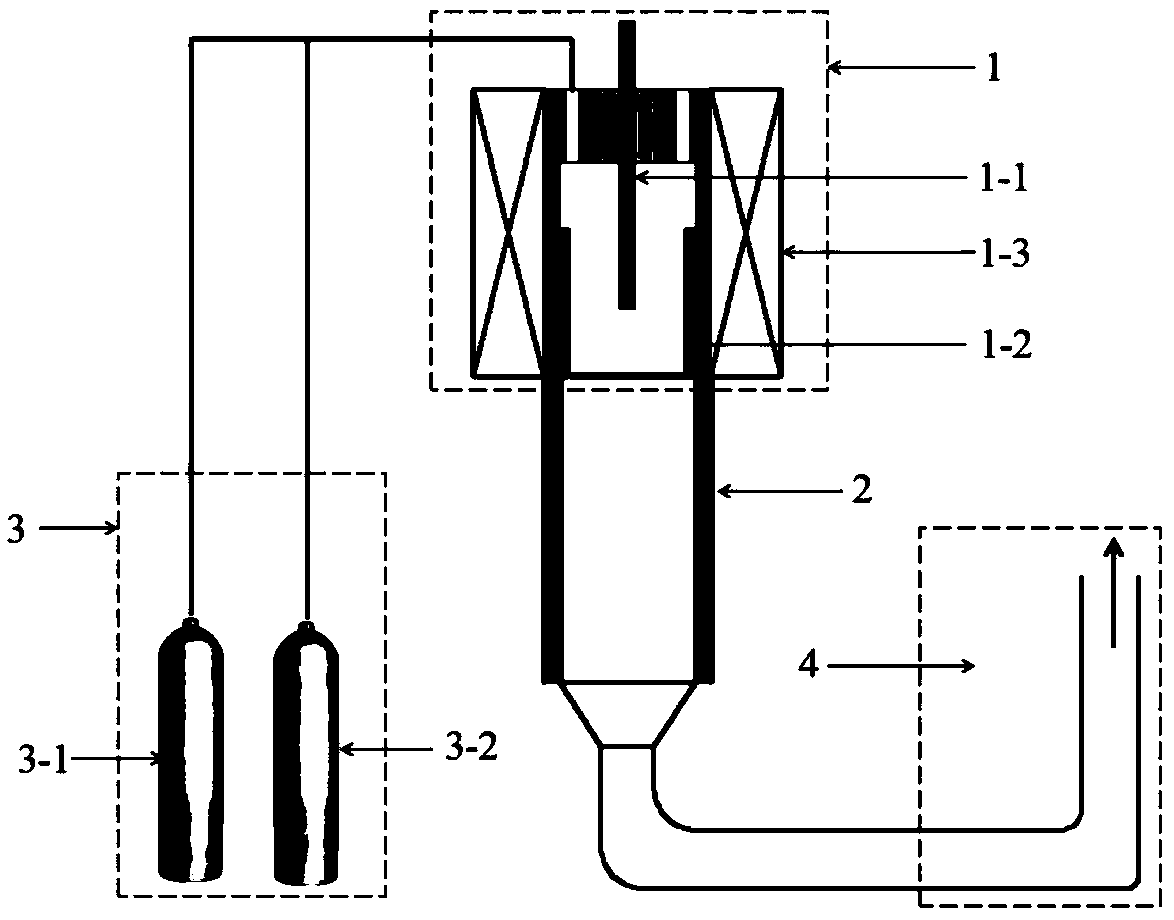

Method used

Image

Examples

Embodiment 1

[0029] The diameter of the cathode of the magnetic rotating arc generator is 10mm, the inner diameter of the anode is 40mm, the material is graphite, and the magnetic field is 0.1T. The magnetic rotating arc working medium gas is a mixed gas of argon and hydrogen, wherein the flow rate of argon is 40slm, and the flow rate of hydrogen is 8slm; the raw material is methane, and the flow rate is 5slm. The magnetic rotating arc discharge current is 100 amperes, the arc rotating speed is about 500 rpm, the arc power is 5.5 kW, and the magnetic rotating arc generator / reactor pressure is 1 bar. After the magnetic rotating arc was operated stably for 5 minutes under the mixed gas atmosphere of argon and hydrogen, methane was fed into the magnetic rotating arc generator, and after 10 minutes of treatment, a total of 12 g of solid products were collected on the inner wall of the reactor.

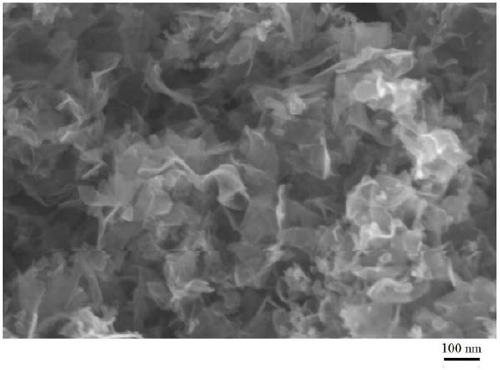

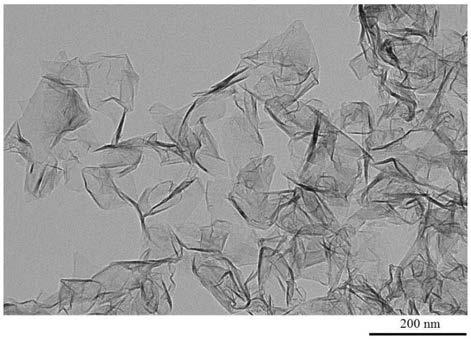

[0030] figure 2 and image 3 Scanning and transmission electron microscopy images of products co...

Embodiment 2

[0032]The diameter of the cathode of the magnetic rotating arc generator is 5mm, the inner diameter of the anode is 30mm, the materials are all stainless steel, and the magnetic field is 0.14T. The magnetic rotating arc working medium gas is a mixed gas of argon and nitrogen, wherein the flow rate of argon gas is 15slm, and the flow rate of nitrogen gas is 5slm; the raw material is propane, and the flow rate is 0.3slm. The magnetic rotating arc discharge current is 0.2 ampere, the arc rotating speed is about 60 rpm, the arc power is about 100 watts, and the magnetic rotating arc generator / reactor pressure is 1 bar. After the magnetic rotating arc was operated stably for 3 minutes under the mixed gas atmosphere of argon and nitrogen, propane was passed into the magnetic rotating arc generator, and after 20 minutes of treatment, a total of 2 g of solid products were collected on the inner wall of the reactor.

[0033] Scanning and transmission electron microscopy images of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com