A kind of ready-mixed permeable concrete and its preparation method and application

A technology of permeable concrete and concrete, which is applied to cohesive pavement, roads, gutters/curbs and other directions paved on site. It can solve the problems that permeable concrete cannot meet the performance requirements, and is suitable for large-scale construction and improvement. Plastic retention and fluidity improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the above-mentioned ready-mixed permeable concrete of the present invention, its specific preparation process is: use commercial mixing station to concentrate and stir, put in cement, silica fume, coarse aggregate first when feeding, add half of the amount of water, and stir for 25 to 35 seconds; Then add polymer emulsion, special plastic retaining agent and polycarboxylate superplasticizer, and stir for 50-65s; finally add the remaining water, and stir for 100-120s; observe the wrapping degree and state of the permeable concrete slurry, and hold it by hand when it is evenly wrapped When the ready-mixed permeable concrete is ready-mixed, the slump of the ready-mixed permeable concrete is 150-180mm, the strength grade is C15-C35, and the flexural strength is 2.0-4.5MPa. , the water permeability coefficient is ≥2.0mm / s, even as high as 5mm / s or more, and the slump loss of the ready-mixed permeable concrete after 2 hours is ≤30mm.

[0047] The app...

Embodiment 1

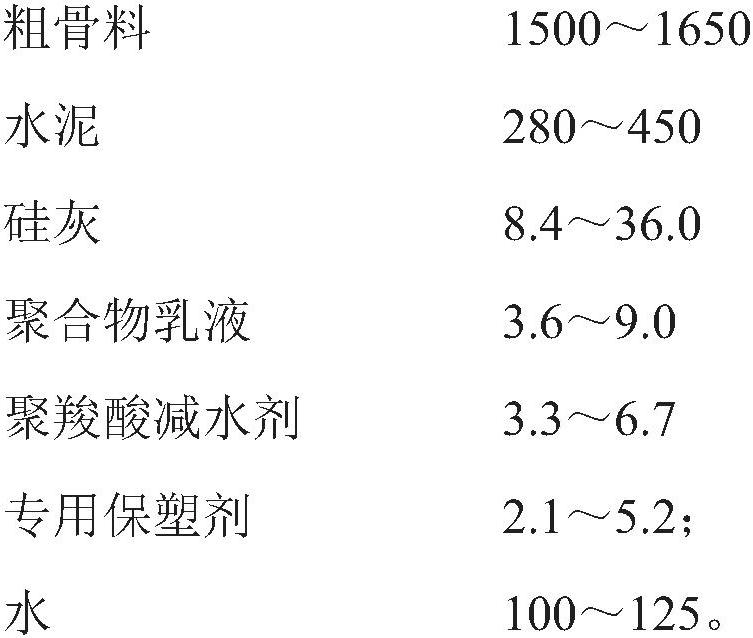

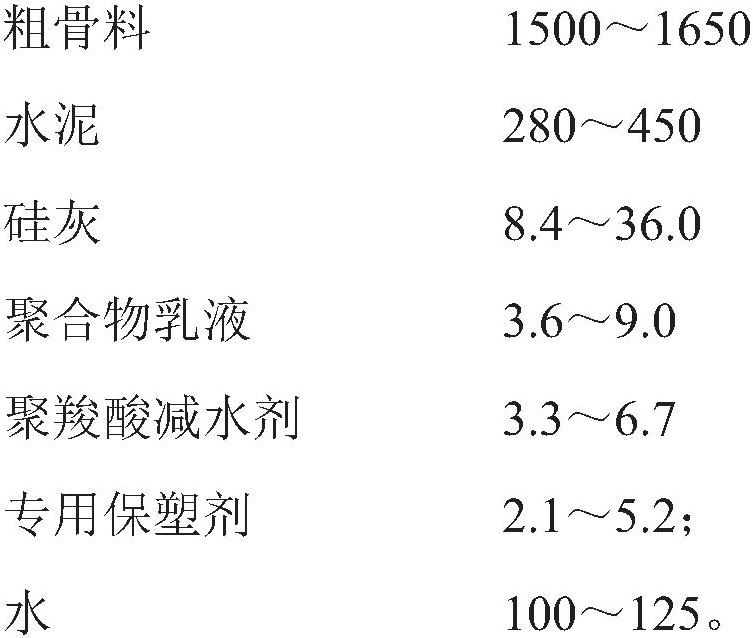

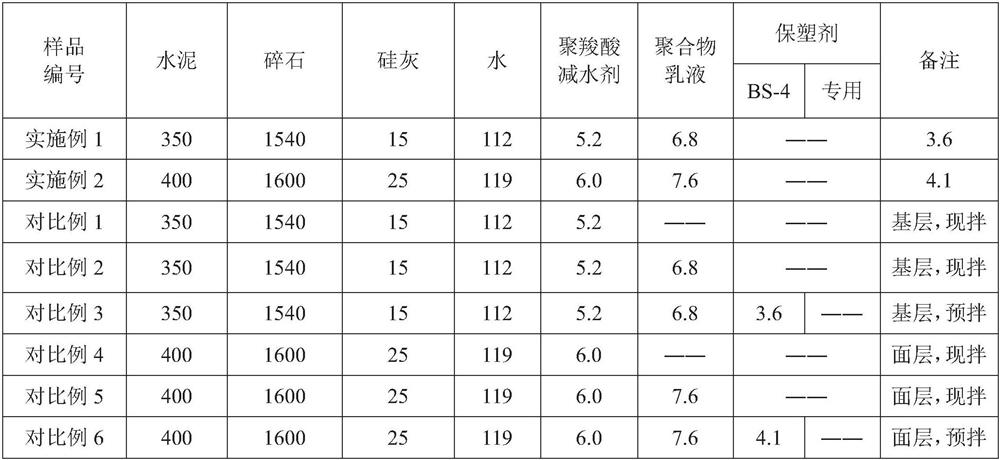

[0058] A kind of ready-mixed permeable concrete according to this embodiment includes cement, coarse aggregate, silica fume, polymer emulsion, special plastic retaining agent, polycarboxylate superplasticizer and water, and the unilateral mass of each component is shown in Table 1 ,in:

[0059] (1) Plastic retaining agent, the plastic retainer of the present embodiment is macromonomer ethylene glycol monovinyl polyglycol ether (EPEG), ethyl acrylate (EA), allyl sodium sulfonate (ALS) and Hydroxyalkyl acrylate (HPA) is an unsaturated monomer compounded with benzoyl peroxide as an initiator and 3-mercaptopropionic acid as a chain transfer agent. The molar ratio of unsaturated monomer n(EPEG) : n(EA): n(ALS): n(HPA)=1: 1.7: 1.2: 2.4, the amount of initiator is 0.6% of the total mass of unsaturated monomers; the amount of chain transfer agent is 0.6% of the total mass of unsaturated monomers 0.2%.

[0060] (2) polymer emulsion, the polymer emulsion of the present embodiment adop...

Embodiment 2

[0075] A kind of ready-mixed permeable concrete according to this embodiment includes cement, coarse aggregate, silica fume, polymer emulsion, special plastic retaining agent, polycarboxylate superplasticizer and water, and the ratio of each component is shown in Table 1. Wherein: the mol ratio n (EPEG) of unsaturated monomer in the plastic retaining agent of present embodiment: n (EA): n (ALS): n (HPA)=1: 1.0: 0.8: 1.8, initiator consumption is not 0.4% of the total mass of saturated monomers; the amount of chain transfer agent is 0.1% of the total mass of unsaturated monomers. The polymer emulsion in this embodiment is an aqueous acrylic resin emulsion with a solid content of 40%; the cement is ordinary Portland cement with a strength grade of 52.5.

[0076] The ready-mixed permeable concrete of this embodiment is concentratedly stirred by a commercial mixing station. When feeding materials, first put cement, silica fume, and coarse aggregate, then add half of the water cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com