Beta nucleating agent, preparation method and application thereof

A β-nucleating agent, pp-g-mah technology, applied in the field of polymer materials, can solve the problems of low quality and small improvement of mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

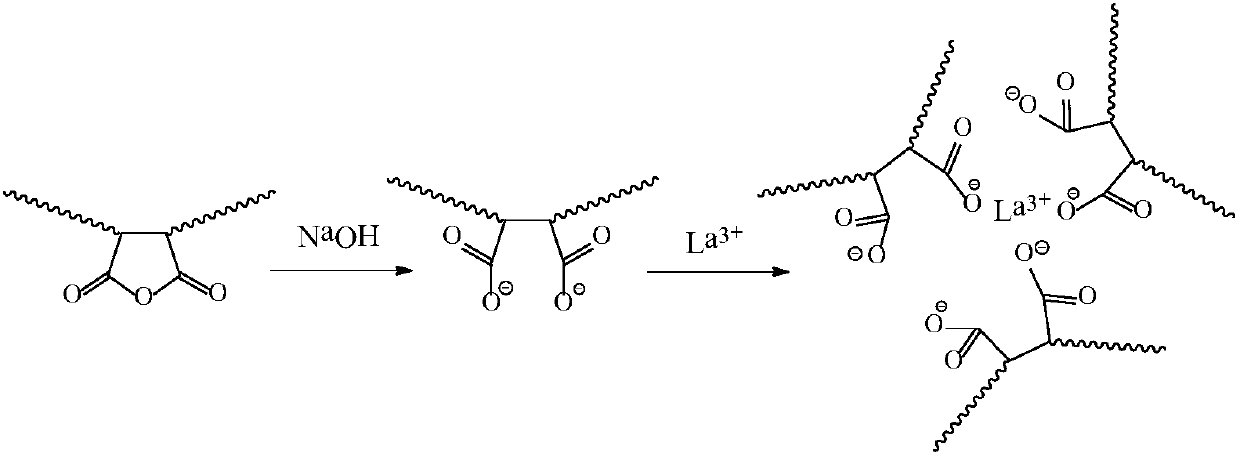

Method used

Image

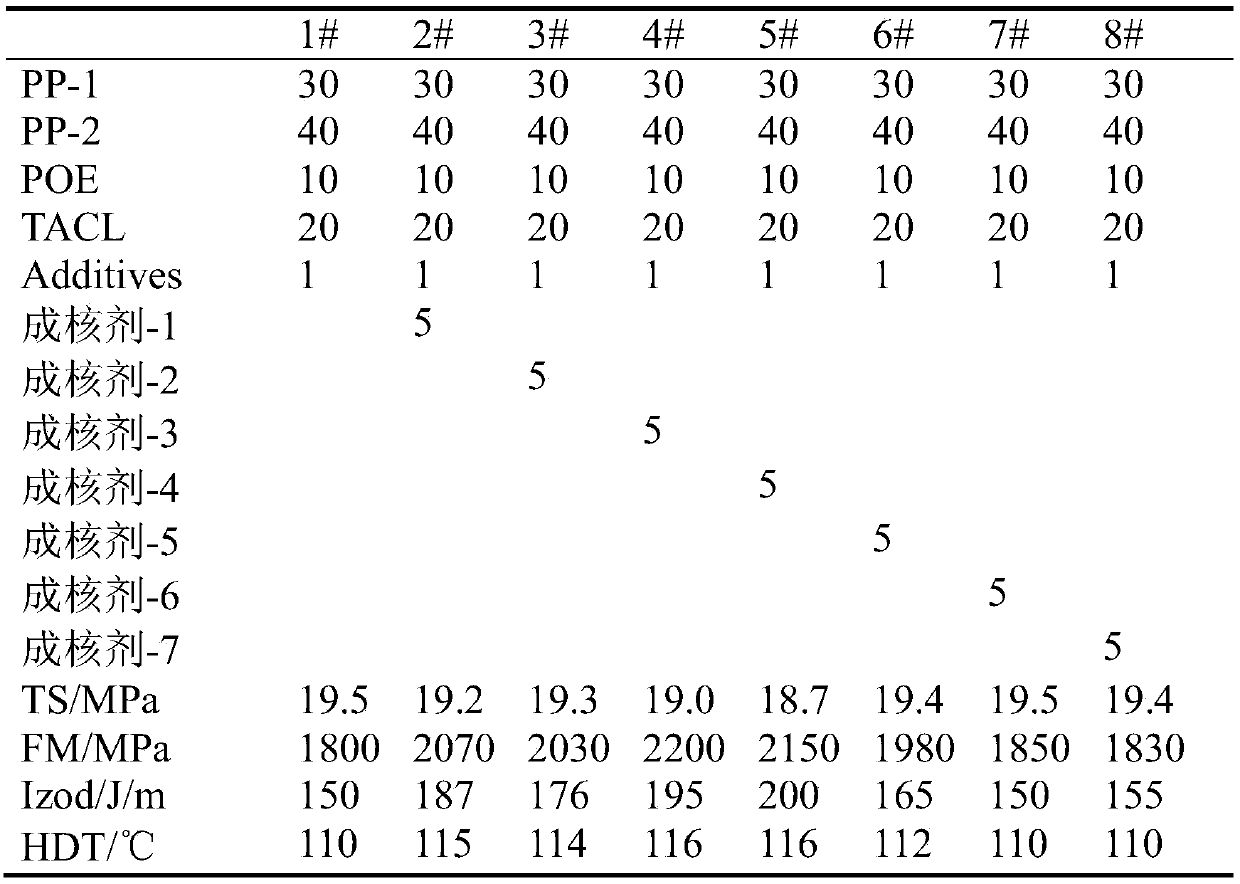

Examples

preparation example Construction

[0051] The preparation method of 0.5mol / L hydrochloric acid standard solution is as follows:

[0052] Weigh 22ml of hydrochloric acid, dilute to 500ml of water, and shake well.

[0053] The calibration method of 0.5mol / L hydrochloric acid standard solution is as follows:

[0054] Weigh 0.95g of the working standard reagent anhydrous sodium carbonate, which is burned in a high-temperature furnace at 270°C-300°C to constant weight, dissolve it in 50ml of water, add 10 drops of bromocresol green-methyl red indicator solution, and use the prepared Titrate the hydrochloric acid solution until the solution turns from green to dark red, boil for 2 minutes, continue to titrate after cooling until the solution turns dark red again, and do a blank experiment at the same time. Then the concentration of the prepared hydrochloric acid standard solution is C(HCl)=1000m / (V 1 -V 2 ) M, where M is 52.994, which is half of the molecular weight of sodium carbonate; V 1 is the volume of hydro...

Embodiment 1

[0056] Put 100 parts of polypropylene BX3920 (purchased from SK, South Korea) in a twin-screw extruder, extrude and granulate to obtain pellets, add the pellets to a flask equipped with a stirring and reflux device, and pour into the flask xylene, and heated and stirred for more than 8 hours to obtain a polypropylene (PP) solution. Among them, polypropylene BX3920 is a copolymerized polypropylene.

[0057] Dissolve 1 part of dibenzoyl peroxide (BPO) and 12 parts of MAH in xylene to obtain a mixed solution, pour the mixed solution into a three-necked flask, install a stirring, reflux and dropping funnel device, and add For the above PP solution, when the mixed solution boils, slowly add the above PP solution dropwise into the three-necked flask. After reacting for 4 hours, pour the liquid in the three-necked flask into a beaker, add acetone, filter under reduced pressure, and wash to obtain a white solid product PP-g-MAH. The grafting rate of maleic anhydride was tested, and t...

Embodiment 2

[0061] Add 100 parts of polypropylene PPH-YD-225 (purchased from Hengyuan Petrochemical) into a flask equipped with a stirring and reflux device, pour xylene into the flask, and heat and stir for more than 8 hours to obtain a PP solution. Among them, polypropylene PPH-YD-225 is homopolymerized polypropylene.

[0062] Dissolve 1 part of dibenzoyl peroxide (BPO) and 12 parts of MAH in xylene to obtain a mixed solution, pour the mixed solution into a three-necked flask, install a stirring, reflux and dropping funnel device, and add the above-mentioned PP solution, when the mixed solution boils, slowly add the above PP solution dropwise into the three-necked flask. After reacting for 4 hours, pour the liquid in the three-necked flask into a beaker, add acetone, filter under reduced pressure, and wash to obtain a white solid product PP-g-MAH. The grafting rate of maleic anhydride was tested, and the result was 4.3%.

[0063] Weigh 10 g of NaOH solid and dissolve it in 200 mL of de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com