Production process of white nylon anti-ultraviolet fabric

A production process, nylon technology, applied in the processing of textile materials, fabric surface trimming, liquid/gas/vapor textile processing, etc., can solve the problem of limiting the use of white anti-ultraviolet fabrics, high ultraviolet transmittance of white fabrics, difficult to achieve National standard requirements, etc., to achieve good dimensional stability, excellent air permeability and coolness, and release the internal stress of grey fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

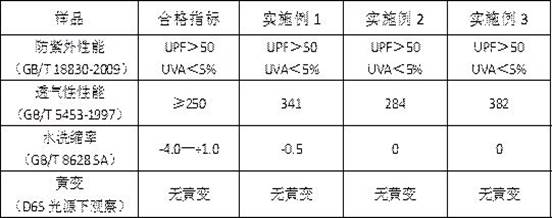

Examples

Embodiment 1

[0030] The production technology of white nylon anti-ultraviolet fabric comprises the following steps:

[0031] Step S1: Weaving. The warp and weft yarns are all made of 40D nylon core-spun yarn and 20D spandex core-spun yarn, which is made of four-way stretch fabric, and the number of warp and weft yarns is above 320T;

[0032] Step S2: washing the gray cloth with water. Using the open-width washing process, the gray cloth is preliminarily washed to release the tension of the gray cloth, and the desizing and refining aids are applied. The desizing and refining aids used include urea, linear alkylbenzene sulfonate, and AEO detergent;

[0033] Step S3: Cold pile treatment. The gray cloth is rolled and stacked for 24 hours;

[0034] Step S4: washing and shrinking. Wash the gray fabric after cold stacking in a tank, the bath ratio of washing and pre-shrinking is 1:10, add 5g / L caustic soda and 2g / L deoiling spirit to remove the oil agent and slurry on the fabric, and further ...

Embodiment 2

[0041] The production technology of white nylon anti-ultraviolet fabric comprises the following steps:

[0042] Step S1: Weaving. The warp and weft yarns are all made of 20D nylon core-spun yarn and 20D spandex core-spun yarn, which is made of four-way stretch fabric, and the number of warp and weft yarns is above 420T;

[0043] Step S2: washing the gray cloth with water. Using the open-width washing process, the gray cloth is preliminarily washed to release the tension of the gray cloth, and the desizing and refining aids are applied. The desizing and refining aids used include urea, linear alkylbenzene sulfonate, and AEO detergent;

[0044] Step S3: Cold pile treatment. The gray cloth is rolled and stacked for 18 hours;

[0045] Step S4: washing and shrinking. Wash the gray fabric after cold stacking in a tank, the bath ratio of washing and pre-shrinking is 1:12, add 3g / L caustic soda and 1g / L deoiling spirit, remove the oil agent and slurry on the fabric, and further el...

Embodiment 3

[0052] The production technology of white nylon anti-ultraviolet fabric comprises the following steps:

[0053] Step S1: Weaving. The warp and weft yarns are all made of 40D nylon core-spun yarn and 20D spandex core-spun yarn, which is made of four-way stretch fabric, and the number of warp and weft yarns is above 320T;

[0054] Step S2: washing the gray cloth with water. Using the open-width washing process, the gray cloth is preliminarily washed to release the tension of the gray cloth, and the desizing and refining aids are applied. The desizing and refining aids used include urea, linear alkylbenzene sulfonate, and AEO detergent;

[0055] Step S3: Cold pile treatment. The gray cloth is rolled and stacked for 21 hours;

[0056] Step S4: washing and shrinking. Wash the gray fabric after cold stacking in a tank, the bath ratio of washing and pre-shrinking is 1:11, add 4g / L caustic soda and 1.5g / L deoiling spirit, remove the oil agent and slurry on the fabric, and further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com