Preparation method of tin nanosphere and carbon nanotube composite electrode material, and product and application thereof

A carbon nanotube composite and electrode material technology, which is applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, battery electrodes, etc., can solve problems such as fast capacity decay, poor charge-discharge cycle stability, and active material powdering and agglomeration , to improve electrical conductivity, prevent agglomeration, and improve cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

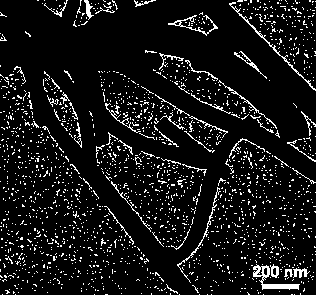

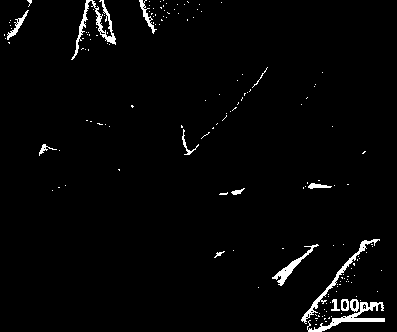

Image

Examples

Embodiment 1

[0025] A method for preparing a composite electrode material of tin nanospheres and carbon nanotubes, using a microporous polymer nanotube material as a load carrier, and preparing a composite electrode material of metal tin and carbon nanotubes through high-temperature carbonization treatment, comprising the following steps:

[0026] a. Preparation of ethanol solution of tin salt: prepare 100 ml of SnCl with a concentration of 50 mg / ml 2 The ethanol solution of adding in the three-neck flask of 250ml;

[0027] b. Nitrogen replacement: replace the air in the above solution with nitrogen through vacuuming-nitrogen filling operation, so that the nitrogen atmosphere is maintained in the three-necked flask;

[0028] c. Add microporous polymer nanotubes: Weigh 30 mg of microporous polymer nanotubes and add them to the solution under nitrogen protection, and stir at room temperature for 6-8 h under nitrogen protection;

[0029] d. Suction filtration and drying: Suction filtration o...

Embodiment 2

[0032] A preparation method of a composite electrode material of tin nanospheres and carbon nanotubes, comprising the steps of:

[0033] a. Preparation of ethanol solution of tin salt: prepare 100 ml of ethanol solution of stannous acetate with a concentration of 50 mg / ml and add it to a 250 ml three-necked flask;

[0034] b. Nitrogen replacement: replace the air in the above solution with nitrogen through vacuuming-nitrogen filling operation, so that the nitrogen atmosphere is maintained in the three-necked flask;

[0035] c. Add microporous polymer nanotubes: Weigh 30 mg of microporous polymer nanotubes and add them to the solution under nitrogen protection, and stir at room temperature for 6-8 h under nitrogen protection;

[0036] d. Suction filtration and drying: Suction filtration of the above mixed solution and collection of solid powder, and vacuum drying of the collected solid powder at 60°C for 3 hours;

[0037] e. High-temperature carbonization treatment: The above-...

Embodiment 3

[0039] A preparation method of a composite electrode material of tin nanospheres and carbon nanotubes, comprising the steps of:

[0040] a. Preparation of ethanol solution of tin salt: prepare 100 ml ethanol solution of dibutyltin dilaurate with a concentration of 50 mg / ml and add it to a 250 ml three-necked flask;

[0041] b. Nitrogen replacement: replace the air in the above solution with nitrogen through vacuuming-nitrogen filling operation, so that the nitrogen atmosphere is maintained in the three-necked flask;

[0042] c. Add microporous polymer nanotubes: Weigh 30 mg of microporous polymer nanotubes and add them to the solution under nitrogen protection, and stir at room temperature for 6-8 h under nitrogen protection;

[0043] d. Suction filtration and drying: Suction filtration of the above mixed solution and collection of solid powder, and vacuum drying of the collected solid powder at 60°C for 3 hours;

[0044] e. High-temperature carbonization treatment: the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com