Application of carbon quantum dot-graphite phase like carbon nitride photocatalytic material to preparation of medicines capable of killing bacteria and promoting skin cicatrice healing

A graphite phase carbon nitride and phase carbon nitride light technology, applied in the field of photocatalytic materials, can solve the problems of low energy consumption, production of carcinogenic by-products, low efficiency, etc., and achieves strong photocatalytic activity, obvious bactericidal effect, and considerable The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

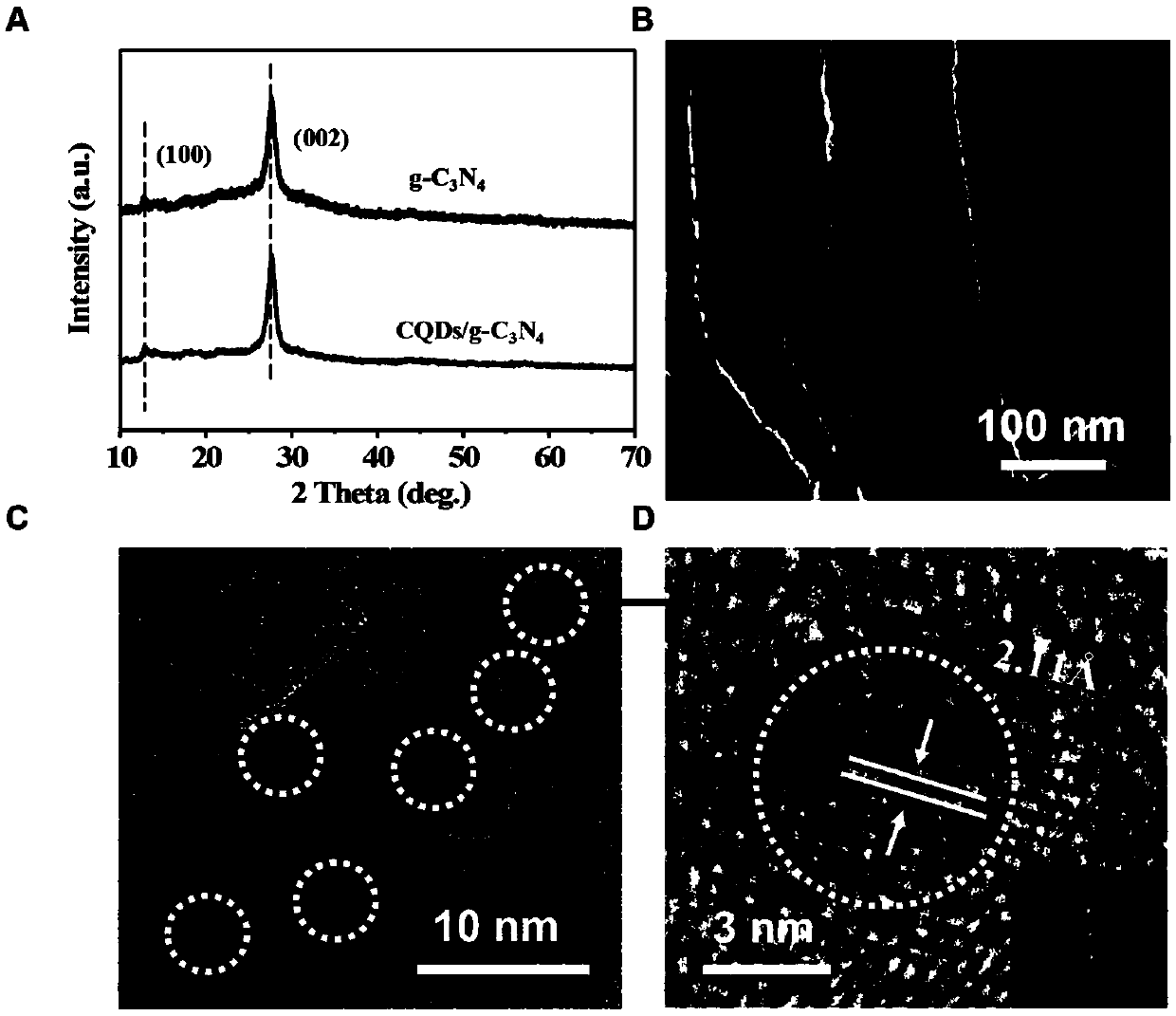

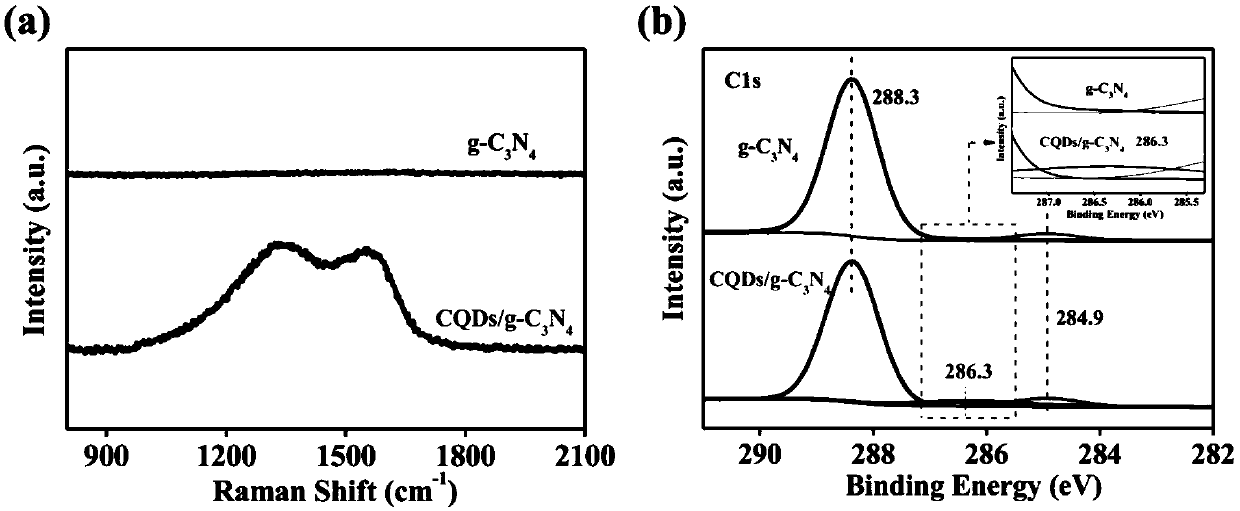

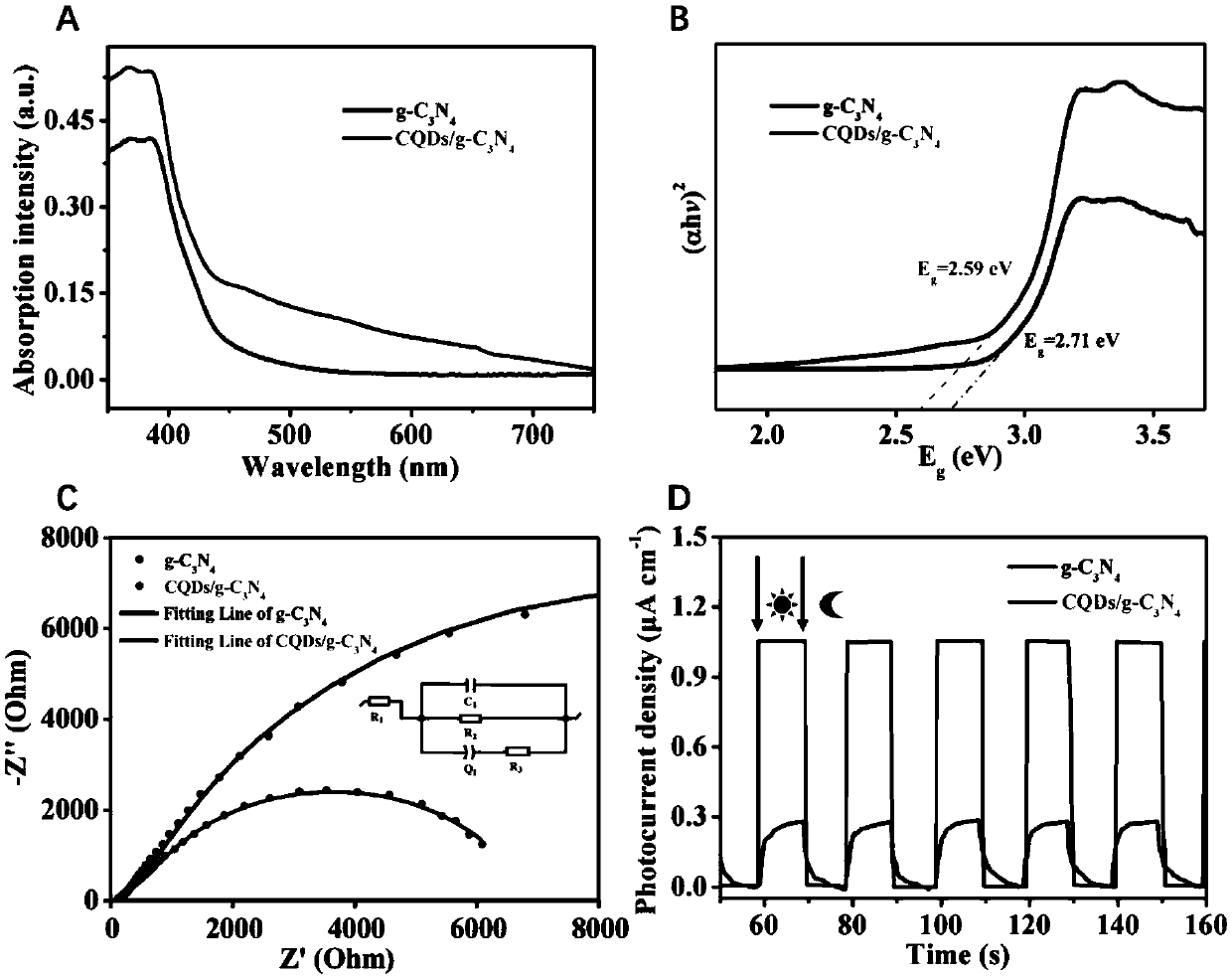

[0046] Example 1CQD s / g -C 3 N 4 preparation of

[0047] 1. Graphite Carbon Nitride (Graphite Carbon Nitride, g-C 3 N 4 )Synthesis

[0048] Put urea (30g) in a ceramic crucible with a lid, and calcined at 550°C for 2 hours at a heating rate of 4°C / min to obtain a light yellow powder, namely g-C 3 N 4 .

[0049] 2. Synthesis of Carbon Quantum Dots (CQDs)

[0050] Dissolve 3g of citric acid and 1mL of ethylenediamine in 30mL of deionized water to obtain a mixed solution I; then transfer the mixed solution I to a 50mL hydrothermal synthesis reactor and heat at 200°C for 5 hours; after the reaction, the reaction The device was naturally cooled to room temperature, and dried at 80° C. for 24 hours to obtain a dark brown powder, which was carbon quantum dots.

[0051] 3. Carbon quantum dots-graphite-like carbon nitride (CQDs / g-C 3 N 4 )Synthesis

[0052] Mix 6mg CQDs with 30mL water to obtain mixed solution II, then add 200mg g-C 3 N 4 Dispersed in mixed solution II; ...

Embodiment 2

[0062] Embodiment 2 carbon quantum dots-like graphitic phase carbon nitride (CQDs / g-C 3 N 4 ) in killing Staphylococcus aureus

[0063] 1. Combine CQDs / g-C 3 N 4 Interact with SA to detect the survival of SA. Samples were taken every 20 minutes, and the number of SA survivors was calculated by standard plate count method.

[0064] S. aureus was cultured in tryptic soy broth (TSB) medium and then resuspended in phosphate buffered saline (PBS, 0.01 M, pH 7.4) to construct the final S. aureus suspension (10 7 CFU mL -1 ). For each sterilization experiment, 50 mL of Staphylococcus aureus suspension and 50 mg of photocatalyst powder were mixed in a beaker. The bacteria and photocatalyst were uniformly mixed on a magnetic stirrer at room temperature while irradiating with a 300W xenon lamp equipped with a UV cut filter (λ-2 . As the reaction proceeds, the mixture is carefully pipetted at predetermined intervals and the bacterial concentration is determined by plate counting....

Embodiment 3

[0071] Embodiment 3 carbon quantum dots-like graphitic phase carbon nitride (CQDs / g-C 3 N 4 ) in the repair of Staphylococcus aureus infected skin

[0072] 1. Divide 6-8 week old C57BL / 6 female mice into untreated group, CQDs / g-C 3 N 4 group and g-C 3 N 4 Group.

[0073] First, a 1.5% amobarbital sodium solution was prepared, and mice were anesthetized by intraperitoneal injection in an amount of 120 μl / 20 g to construct a SA skin infection model.

[0074] Then, 80mm of skin was made on the back skin of mice in each group. 2 area of sterile wound, place 1 x 10 7 CFU of Staphylococcus aureus smeared on the window, followed by 100mg of CQDs / g-C on the back 3 N 4 or g-C 3 N 4 , irradiated for 2 hours under light conditions.

[0075] The area and bacterial load of skin scars in each group were observed.

[0076] It was found that: with g-C 3 N 4 Group comparison, CQDs / g-C 3 N 4 Skin scars healed faster in mice in the group (see Figure 6 ).

[0077] 2. Combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com