Skincare antibacterial microcapsule finishing agent and preparation method and application thereof

A microcapsule finishing and microcapsule technology, which is applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve the problems of unsatisfactory washing resistance, poor mechanical properties and thermal stability, etc., and achieve long-lasting and durable skin care antibacterial function , good heat resistance, the effect of good heat resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

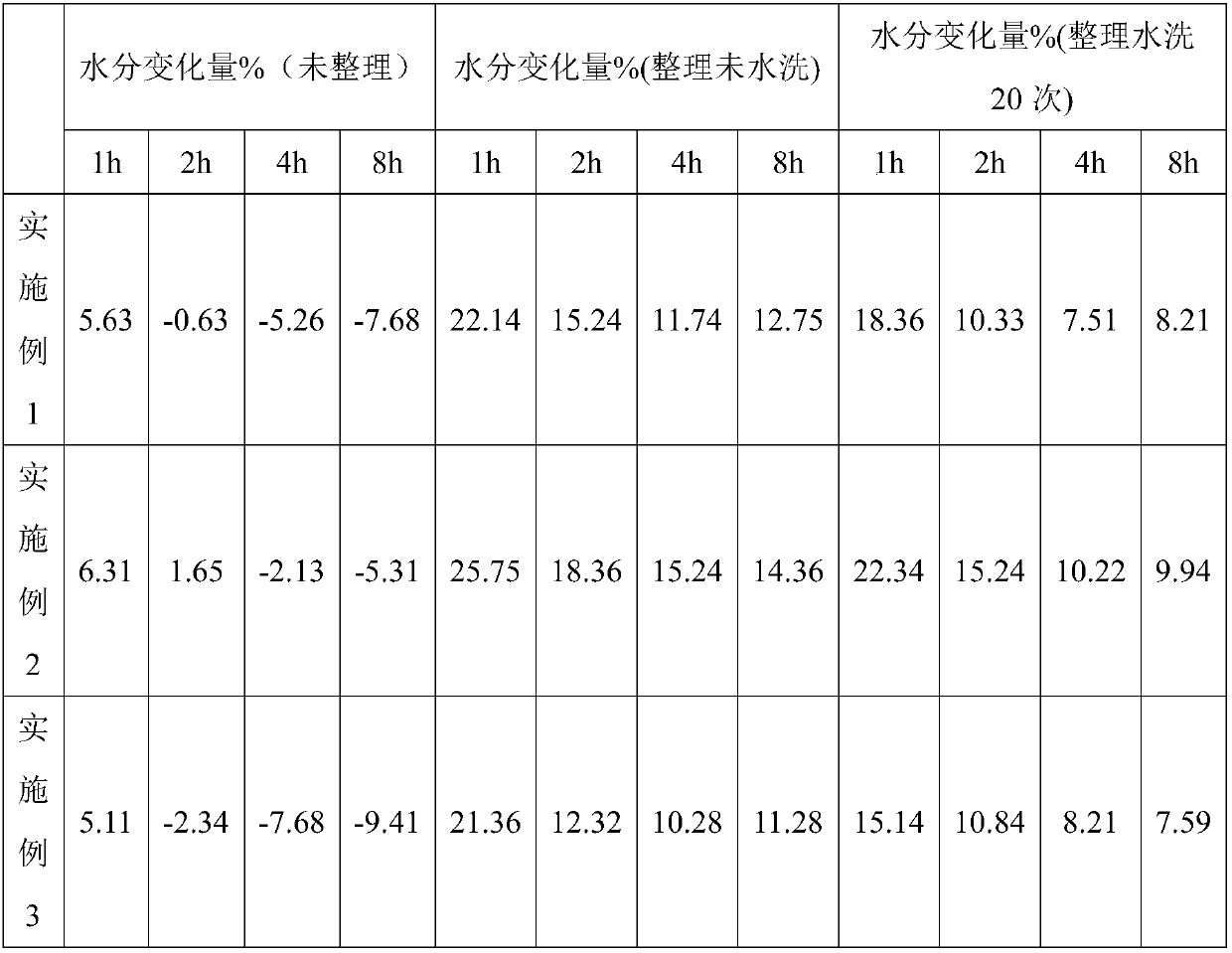

Examples

Embodiment 1

[0030] The preparation of non-adhesive skin care antibacterial microcapsule finishing agent comprises the following steps:

[0031] (1) Take 5g of aloe vera extract, 5g of squalene and 1g of Tween-20 respectively, add them to 500g of deionized water, stir ultrasonically at 50°C for 30min to obtain the core material emulsion, control the ultrasonic frequency to 300W, and the stirring rate to 1500r / min ;

[0032] (2) Prepare a 20% TEOS aqueous solution, adjust the pH to 3 with 2mol / L hydrochloric acid, stir at 30°C for 25 minutes to obtain a wall material hydrolyzate, and the stirring rate is 300r / min;

[0033] (3) Slowly add 50g of wall material hydrolyzate into 500g of core material emulsion, adjust pH to 9 with 2mol / L NaOH solution, stir at 50°C for 4h, filter and wash, dry at 60°C to obtain white microcapsule solid, drop The acceleration is 20 drops / min, and the stirring rate is 500r / min;

[0034] (4) Take 10g of microcapsule solids and 30g of acidic ethanol aqueous soluti...

Embodiment 2

[0038] The preparation of non-adhesive skin care antibacterial microcapsule finishing agent comprises the following steps:

[0039] (1) Take 4g of aloe vera extract, 6g of squalene and 1g of Tween-60 respectively, add them to 500g of deionized water, and stir ultrasonically at 50°C for 40min to obtain the core material emulsion, control the ultrasonic frequency to 400W, and the stirring rate to 1200r / min

[0040] (2) Prepare a 20% TEOS aqueous solution, adjust the pH to 3 with 1mol / L hydrochloric acid, stir at 30°C for 25 minutes to obtain a wall material hydrolyzate, and the stirring rate is 300r / min;

[0041](3) Slowly add 50g of the wall material aqueous solution to 500g of the core material emulsion, adjust the pH to 9 with 2mol / L NaOH solution, stir at 50°C for 4h, filter and wash, dry at 60°C to obtain white microcapsule solids, drop rate 20 drops / min, the stirring rate is 500r / min;

[0042] (4) Take 10g of microcapsule solids and 30g of acidic ethanol aqueous solution ...

Embodiment 3

[0046] The preparation of non-adhesive skin care antibacterial microcapsule finishing agent comprises the following steps:

[0047] (1) Take 5g of aloe extract, 5g of squalene and 1g of Tween-20 respectively, add them to 500g of deionized water, stir ultrasonically at 50°C for 30min to obtain the core material emulsion, control the ultrasonic frequency to 400W, and the stirring rate to 1200r / min

[0048] (2) Prepare a TEOS aqueous solution with a concentration of 15%, adjust the pH to 3 with 1mol / L hydrochloric acid, stir at 30°C for 20 minutes to obtain a wall material hydrolyzate, and the stirring rate is 300r / min;

[0049] (3) Slowly add 50g of the wall material aqueous solution to 400g of the core material emulsion, adjust the pH to 9 with 2mol / L NaOH solution, stir at 50°C for 3h, filter and wash, dry at 60°C to obtain white microcapsule solids, drop rate 30 drops / min, the stirring rate is 500r / min;

[0050] (4) Take 10 g of microcapsule solids and 50 g of acidic ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com