Non-catalytic reforming reactor and technology thereof

A reforming reactor, reforming reaction technology, applied in chemical/physical/physical-chemical stationary reactors, detailed information of chemical/physical/physical-chemical reactors, control/adjustment processes, etc., can solve the problem of reducing production efficiency. , the mechanical and electronic characteristics of the complex control of the injection device, the increase in cost, etc., to achieve the effect of reducing the soot rate, high productivity, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

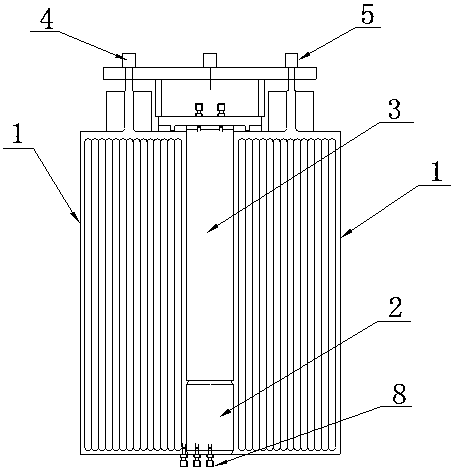

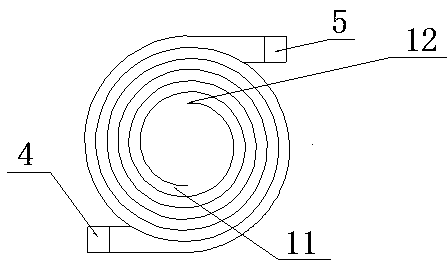

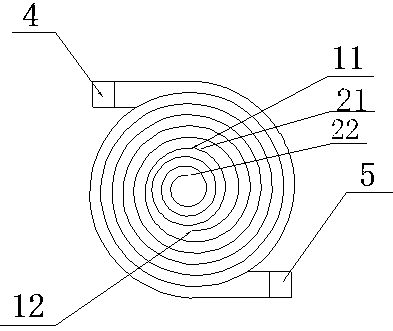

[0046] Such as Figure 1~9 As shown, a non-catalytic reforming reactor includes a heat exchange zone 1, a mixing zone 2, and a reforming reaction zone 3, and is characterized in that: the heat exchanging zone 1 is in the outer layer, and the inner layer is a mixing zone 2 and a reforming reaction zone 3; the mixing zone 2 is located below the reforming reaction zone 3;

[0047] Heat exchange zone 1 is constructed layer by layer into an end-to-end Swiss roll structure through direct metal laser sintering technology; heat exchange zone 1 realizes heat exchange through the opposite flow of air and product; mixing zone 2 is a detachable spiral tube road 7 structure;

[0048] The reforming reaction zone 3 has a cylindrical structure and is located above the mixing zone 2;

[0049] The air outlet 11 of the heat exchange zone 1 is connected with the air inlet 6 of the mixing zone; the outlet 10 of the mixing zone is connected with the inlet of the reforming reaction zone 3; the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com