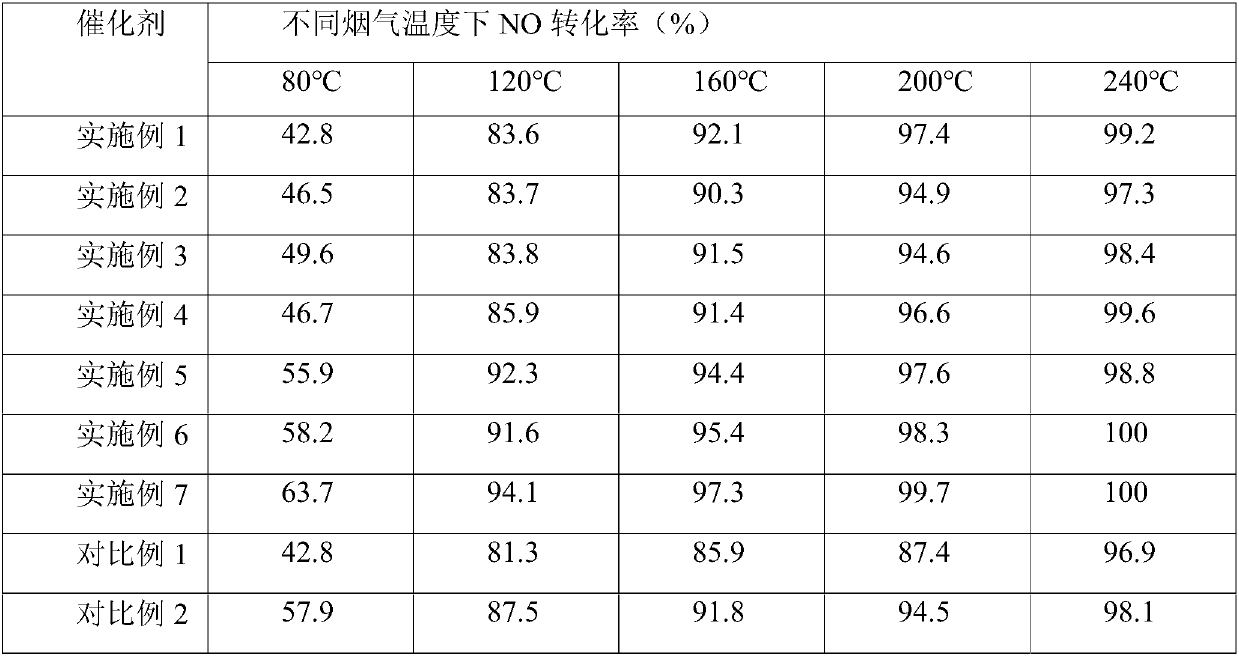

Manganese-based low-temperature flue gas denitration catalyst and preparation method thereof

A denitrification catalyst and low-temperature flue gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of easy poisoning and deactivation, low denitrification efficiency, etc., achieve wide application range and improve denitrification activity , Improve the effect of catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of a manganese-based low-temperature flue gas denitrification catalyst, comprising the following steps:

[0047] (1) Grind the fly ash to 4-20um, add 3-15% dilute nitric acid solution to the fly ash, the mass ratio of fly ash to nitric acid solution is 1:3-50, stir at room temperature for 30-120min Carry out modification, the modified fly ash is washed with deionized water until neutral, and dried at 120°C;

[0048] (2) Mix the modified fly ash and TiO 2 Mechanically mix evenly;

[0049] (3) Deionized water is used to configure an oxalic acid solution with a concentration of 5%, and the cerium salt, tungsten salt, tin salt, and iron salt precursor are dissolved in the oxalic acid solution to form a metal salt solution, and the temperature of the solution is controlled at 45-75° C.;

[0050] (4) add manganese nitrate solution or manganese acetate solution in (3) solution;

[0051] (5) Add the mixed carrier in st...

Embodiment 1

[0056] 1. Grind 65g of fly ash to 4-20um, add 500ml of dilute nitric acid solution with a concentration of 10% to the fly ash and stir for 60min at room temperature for modification. The modified fly ash is washed with deionized water to Neutral, dry at 120°C for 4 hours;

[0057] 2. Mix 50g of modified fly ash with 50g of anatase TiO 2 Mix evenly with a ball mill;

[0058] 3. Prepare 200ml of oxalic acid solution with a concentration of 5%, and control the temperature of the solution at 55°C, and dissolve 12.61g of cerium nitrate hexahydrate in the dilute oxalic acid solution;

[0059] 4, add 41.17g 50% manganese nitrate solution in (3) solution;

[0060] 5. Add the mixed carrier in step (2) to the solution prepared in step (4), stir evenly, and impregnate. The impregnation temperature is 85°C, and the impregnation time is 4 hours;

[0061] 6. Dry the slurry obtained by impregnating in step (5) at 110° C. for 8 hours, and bake at 450° C. for 6 hours in an air atmosphere to...

Embodiment 2

[0064] 1. Grind 65g of fly ash to 4-20um, add 500ml of dilute nitric acid solution with a concentration of 10% to the fly ash and stir for 60min at room temperature for modification. The modified fly ash is washed with deionized water to Neutral, dry at 120°C for 4 hours;

[0065] 2. Mix 50g of modified fly ash with 50g of anatase TiO 2 Mix evenly with a ball mill;

[0066] 3. Prepare 200ml of oxalic acid solution with a concentration of 5%. The temperature of the solution is controlled at 55°C, and 6.03g of ammonium metatungstate is dissolved in the dilute oxalic acid solution;

[0067] 4. Add 41.17g50% manganese nitrate solution to (3) solution;

[0068] 5. Add the mixed carrier in step (2) to the solution prepared in step (4), stir evenly, and impregnate. The impregnation temperature is 85°C, and the impregnation time is 4 hours;

[0069] 6. Dry the slurry obtained by impregnating in step (5) at 110° C. for 8 hours, and bake at 450° C. in an air atmosphere for 6 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com