Poly(p-phenylene vinylene) derivative containing biphenyl structure and cyano group and preparation method and application thereof

A technology of poly(p-phenylene) and biphenyl structure, which is applied in the field of preparation and application of poly(p-phenylene) derivatives containing biphenyl structure and cyano group, can solve the problem of less application of PPV materials, and achieve good Wetting ability, high thermal stability, effect of increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

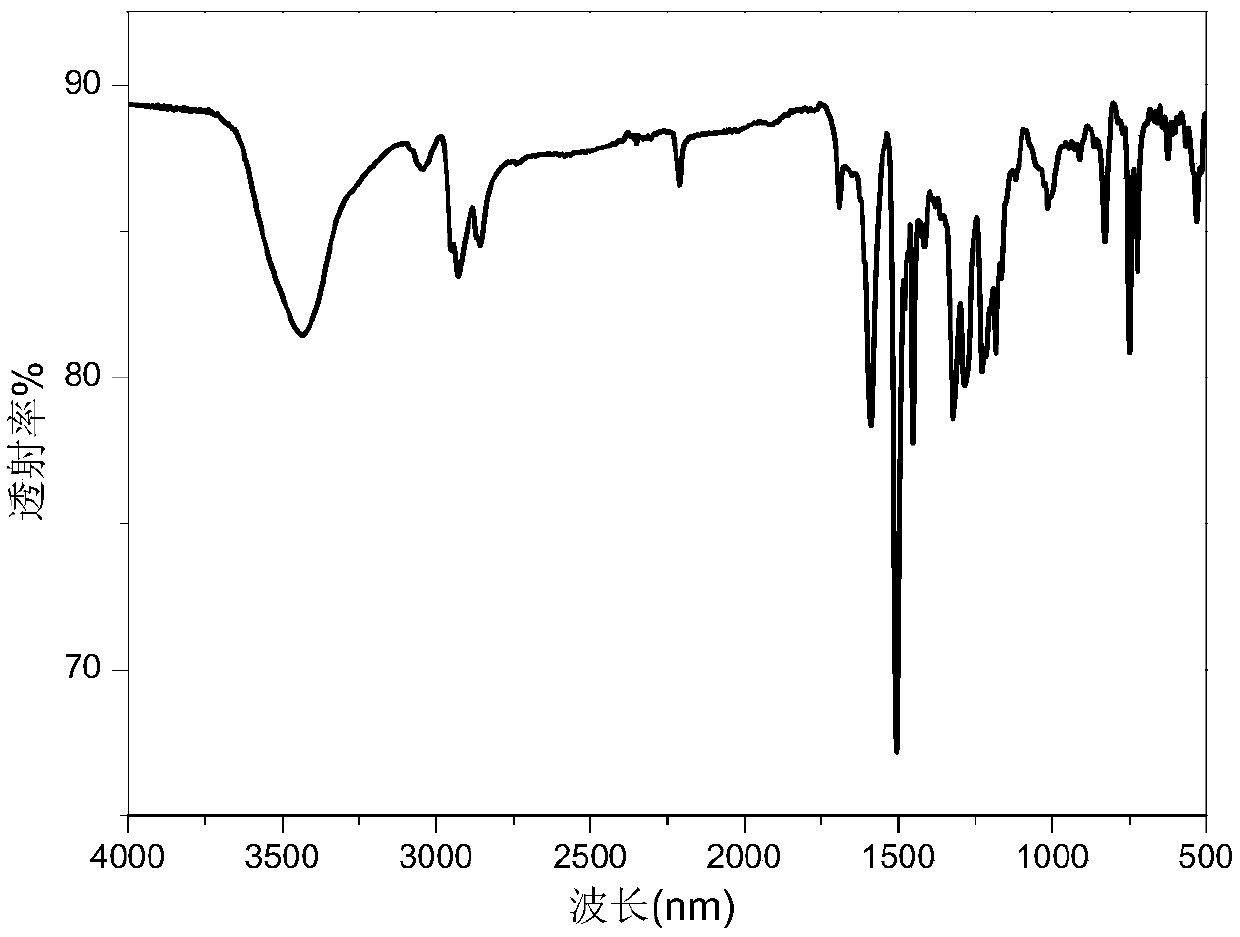

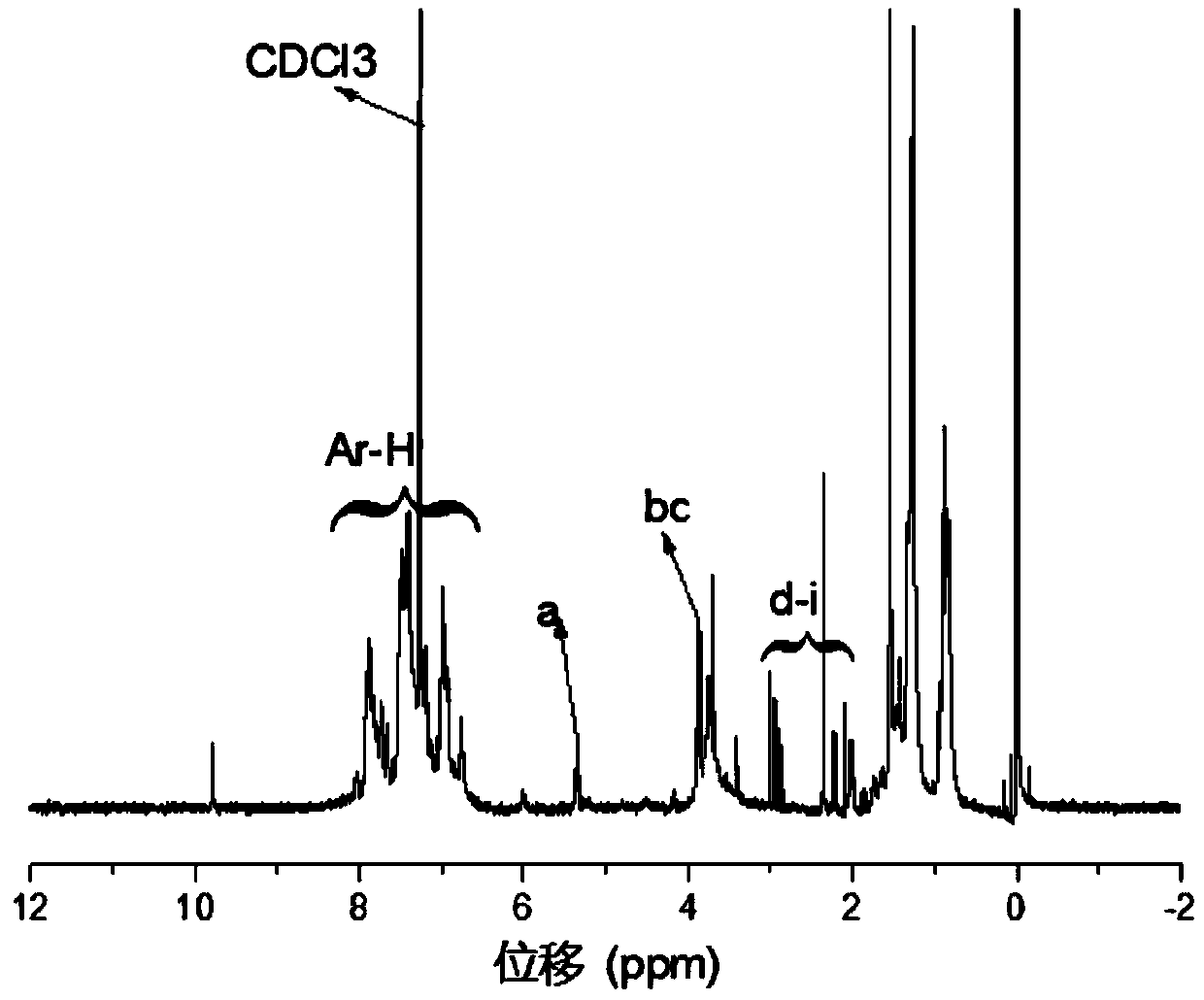

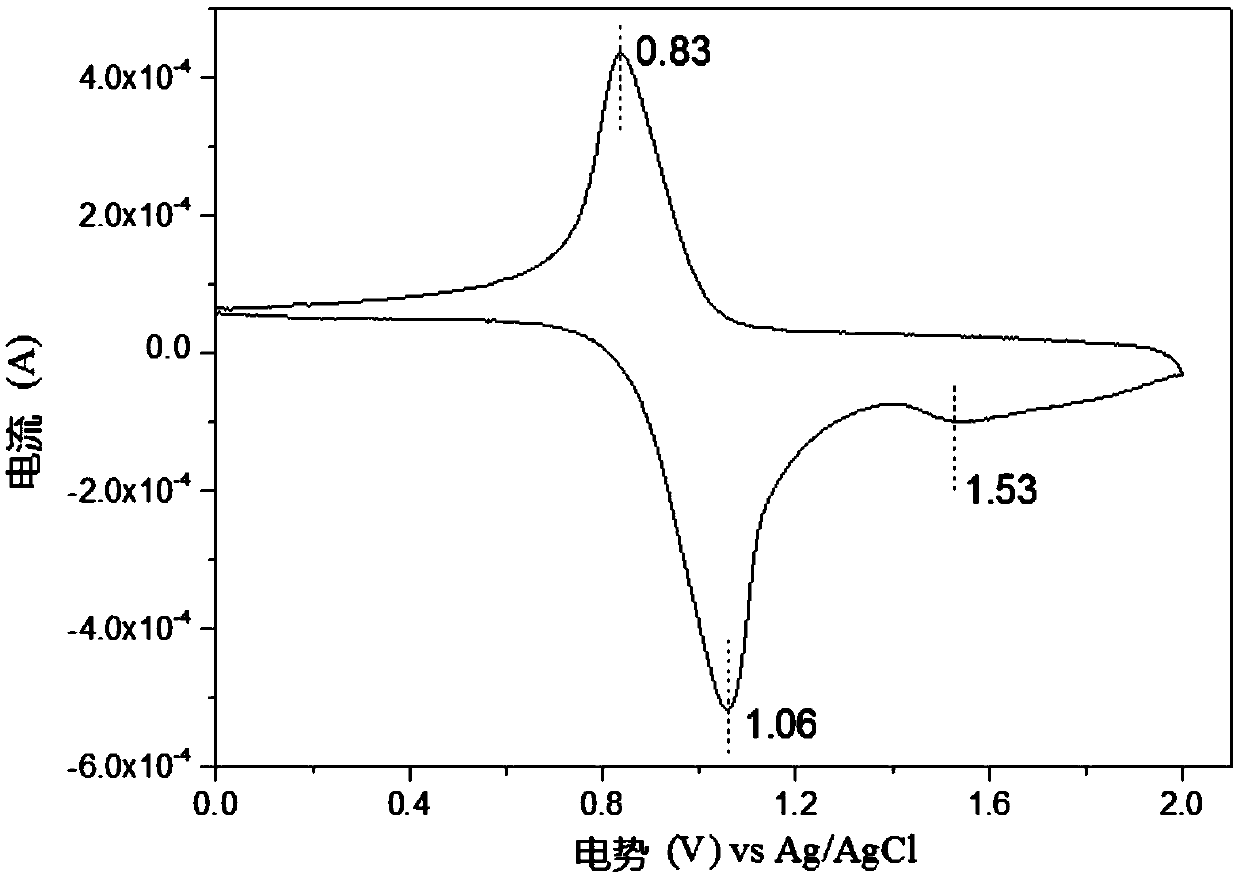

[0031] Specific embodiment 1: In this embodiment, the structural formula of poly(p-phenylene) derivatives containing biphenyl structure and cyano group is as follows:

[0032] ,

[0033] In the formula, n is an integer of 3-10.

[0034] The beneficial effect of this implementation mode:

[0035] This embodiment greatly expands the application range of PPV materials. Poly(p-styrene) polymer materials with cyano groups containing long carbon chains have aroused great interest of scientific researchers due to their excellent heat resistance and mechanical properties. . Introducing biphenyl and long carbon chains with disruptive stacking properties into the poly(p-phenylene) structure can not only maintain the high thermal stability of the original poly(p-styrene), but also increase its solubility and enhance the film-forming ability, which not only It is conducive to the manufacture of large-area thin-film electrochromic devices, and also provides electroactive centers to fa...

specific Embodiment approach 2

[0037] Specific implementation mode two: the preparation method of poly(p-phenylene vinylene derivative) containing biphenyl structure and cyano group in this implementation mode is as follows:

[0038] 1. Synthesis of dialdehyde monomers containing biphenyl structure

[0039] Mix dicyanobiphenyl diamine and dehydrated toluene, vacuumize and ventilate nitrogen, then place in a low-temperature reaction kettle, cool down to -70 degrees Celsius, add reducing agent diisobutyl aluminum hydride, and stir for 10 minutes at -70 degrees Celsius , close the cooling valve, keep stirring until the temperature of the reaction system rises to room temperature, take out the reaction system and place it on a magnetic stirrer to continue stirring, then add acetone, ethyl acetate, and ammonia solution of ammonium chloride in sequence, and stir until the system appears to be clearly stratified , the upper layer is a clear liquid, and the lower layer has solid precipitation, the system is suction...

specific Embodiment approach 3

[0048] Specific embodiment three: this embodiment is different from specific embodiment two in that: in step one, vacuum pumping and nitrogen flow are repeated three times. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com