Antireflection coating for solar glass with anti-ash function, preparation method thereof, and anti-ash high anti-reflection solar glass

A solar glass, anti-reflection technology, applied in conductive coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of easy adsorption of stains, blue light, high refractive index, reduce power generation efficiency attenuation, and suppress dust. The effect of simple attachment and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

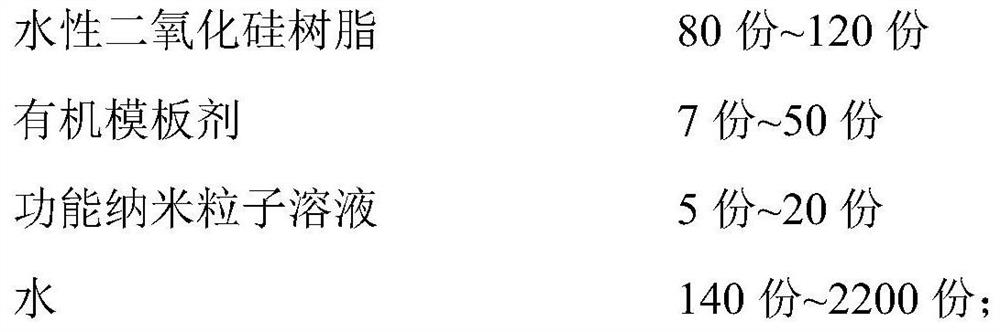

[0047] A solar glass anti-reflection coating with anti-ash function, which consists of the following components in parts by weight:

[0048]

[0049] Wherein, the functional nanoparticle solution is composed of the following components in parts by weight:

[0050] Needle-shaped nano-ATO 10 parts

[0051] Nano NTO 10 parts

[0052] 100 parts of water.

[0053] In this embodiment, the organic template is acrylic resin.

[0054] In this embodiment, the aspect ratio of the needle-rod nano-ATO is 100.

[0055]In this embodiment, the nano-NTO is the nano-NTO with the product model RS-301 produced by Liuzhou Ruosi Nano Material Technology Co., Ltd.

[0056] In this embodiment, the water-based silica resin is the water-based silica resin of model SJ101 produced by Zongyang County Sanjin Pigment Co., Ltd.

[0057] Above-mentioned a kind of preparation method of solar glass anti-reflection coating with anti-ashing function, it comprises the following steps:

[0058] Step 1, rea...

Embodiment 2

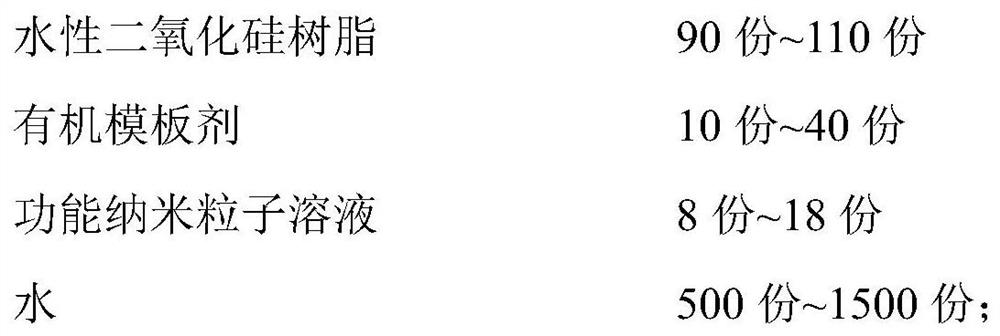

[0062] A solar glass anti-reflection coating with anti-ash function, which consists of the following components in parts by weight:

[0063]

[0064] Wherein, the functional nanoparticle solution is composed of the following components in parts by weight:

[0065] Carbon nanotubes 5 parts

[0066] Nano NTO 5 parts

[0067] 90 parts of water.

[0068] In this embodiment, the organic template is an acrylic emulsion.

[0069] In this embodiment, the aspect ratio of the needle-rod nano-ATO is 10.

[0070] In this embodiment, the nano-NTO is the nano-NTO with the product model RS-301 produced by Liuzhou Ruosi Nano Material Technology Co., Ltd.

[0071] In this embodiment, the water-based silica resin is a water-based silica resin with a product model of A-10-9 produced by Shanghai Ruiju Polymer Material Co., Ltd.

[0072] Above-mentioned a kind of preparation method of solar glass anti-reflection coating with anti-ashing function, it comprises the following steps:

[0073]...

Embodiment 3

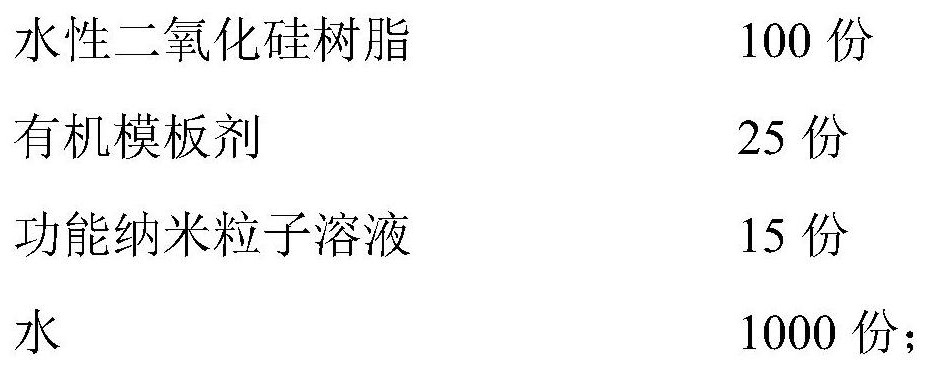

[0077] A solar glass anti-reflection coating with anti-ash function, which consists of the following components in parts by weight:

[0078]

[0079] Wherein, the functional nanoparticle solution is composed of the following components in parts by weight:

[0080] Needle-shaped nano-ATO and carbon nanotubes 15 parts

[0081] Nano NTO 15 parts

[0082] 110 parts of water.

[0083] In this embodiment, the organic templating agent is polyurethane emulsion.

[0084] In this embodiment, the aspect ratio of the needle-rod nano-ATO is 200.

[0085] In this embodiment, the nano-NTO is the nano-NTO with the product model RS-301 produced by Liuzhou Ruosi Nano Material Technology Co., Ltd.

[0086] In this embodiment, the water-based silica resin is the product model WA-2001S produced by Guangzhou Jiuwei Trading Co., Ltd.

[0087] Above-mentioned a kind of preparation method of solar glass anti-reflection coating with anti-ashing function, it comprises the following steps:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com