Preparation method of rare earth/silane doped composite superhydrophobic functional coating

A super-hydrophobic, silane hydrolyzate technology, used in coatings, metal material coating processes, anti-corrosion coatings, etc., can solve problems such as unfavorable environmental protection and personal safety, poor corrosion resistance, complex processes, etc., to improve self-cleaning performance, Improve mechanical stability and improve the effect of bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

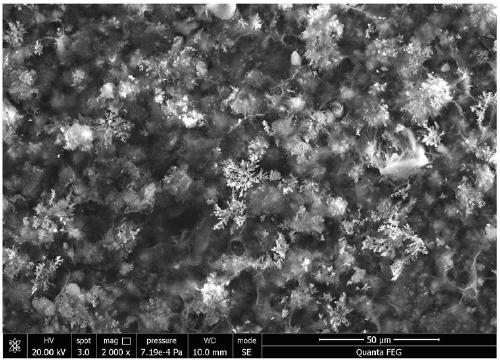

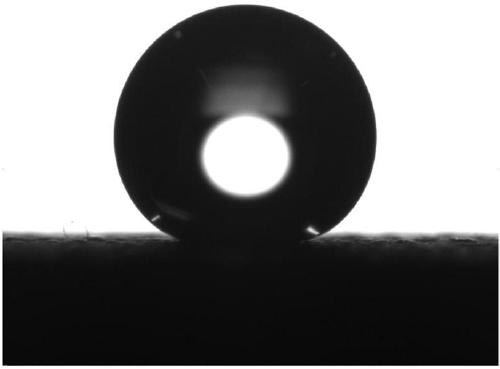

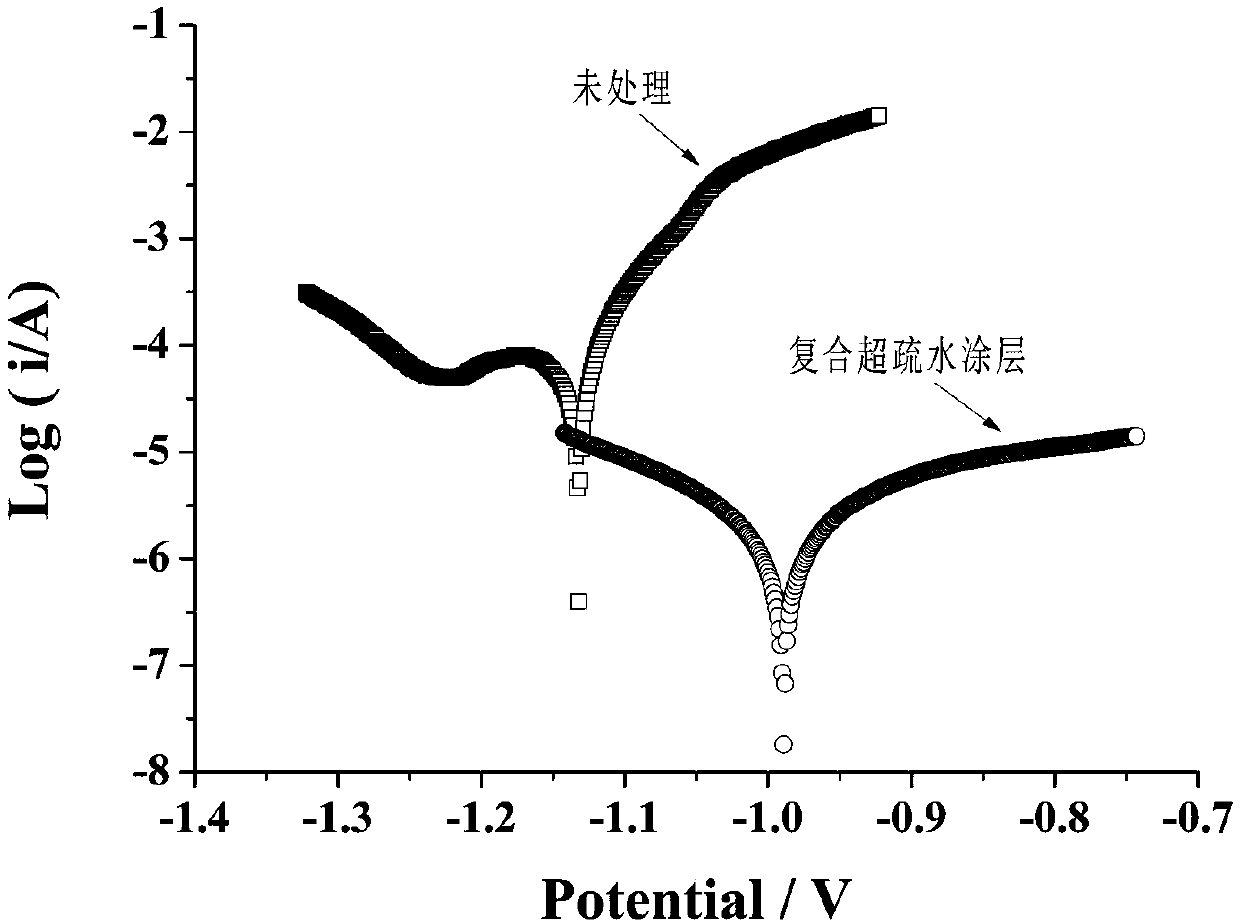

[0024] The invention is a preparation method of a rare earth / silane doped composite superhydrophobic functional coating, comprising the following steps:

[0025] (1) Preparation of silane hydrolyzate: with silane coupling agent, deionized water, organic solvent, prepare silane solution by silane coupling agent: deionized water: organic solvent=5:5:90 (volume ratio), apply magnetic stirring 15min~30min, put it at room temperature and carry out hydrolysis for 6~24h until the silane solution becomes clear, then use 0.05~1mol / L acetic acid solution or 0.05~1mol / L ammonia solution to adjust the pH to 4~5 to obtain silane Hydrolyzate;

[0026] (2) Preparation of rare earth-doped mixed fatty acid solution: prepare long-chain fatty acid ethanol solution with a concentration of 0.02mol / L~0.1mol / L for later use; dissolve 0.2~0.4 parts of silver nitrate and 0.43~2.17 parts of rare earth salt in 1 ~5 parts of dilute nitric acid aqueous solution, add dropwise into 50 parts of long-chain f...

Embodiment 1

[0037] Vinyltrimethoxysilane, deionized water, absolute ethanol, according to silane coupling agent: deionized water: absolute ethanol = 5:5:90 (volume ratio) to prepare 50ml of silane solution, apply magnetic stirring for 15min, set Carry out hydrolysis at room temperature for 12 hours until the silane solution becomes clear, then adjust the pH to 4-5 with 1mol / L acetic acid solution, and take 50ml for later use. Dissolve 0.24g of silver nitrate and 0.5g of cerium nitrate in 3ml of dilute nitric acid aqueous solution, add dropwise to 50ml of stearic acid-ethanol solution with a concentration of 0.05mol / L under the action of magnetic stirring, and continue stirring for 15min until the solution becomes clear . Then, it was fully mixed with 50ml of silane hydrolyzate at a volume ratio of 1:1, and stirred evenly to obtain a composite deposition solution.

[0038] Clean the galvanized steel sheet with a degreasing agent and deionized water, immerse it in the above composite depos...

Embodiment 2

[0041] With γ-aminopropyltriethoxysilane, deionized water, absolute ethanol, prepare 50ml silane solution according to silane coupling agent: deionized water: absolute ethanol=5:5:90 (volume ratio), apply magnetic force Stir for 15 minutes, place at room temperature and carry out hydrolysis for 12 hours until the silane solution becomes clear, then use 1mol / L acetic acid solution to adjust the pH to 4-5, and take 50ml for later use. Dissolve 0.2g of silver nitrate and 0.6g of lanthanum nitrate in 5ml of dilute nitric acid aqueous solution, add dropwise to 50ml of 0.02mol / L myristic acid-ethanol solution under magnetic stirring, and continue stirring for 15min until the solution becomes clear. Then, it was fully mixed with 50ml of silane hydrolyzate at a volume ratio of 1:1, and stirred evenly to obtain a composite deposition solution.

[0042] Clean the galvanized steel sheet with a degreasing agent and deionized water, immerse it in the above composite deposition solution for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com