Preparation method of cobalt selenide/graphite carbon composite material

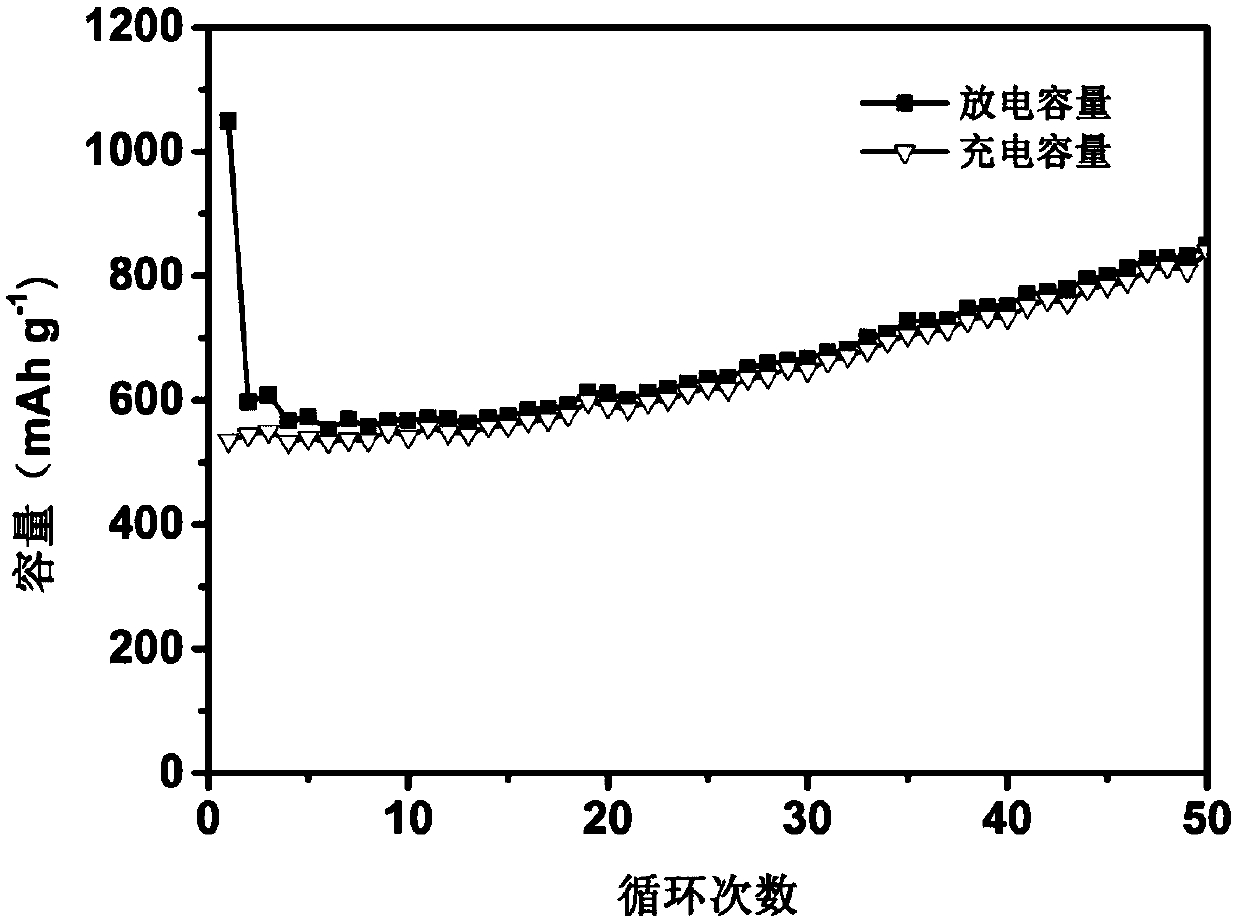

A composite material and graphitic carbon technology, applied in electrochemical generators, structural parts, electrical components, etc., can solve the problems of inability to form homogeneous distribution, the current is suddenly large and small, and the electric shock capacity is small, and the preparation process is simple and feasible. , The effect of large electric shock capacity and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of cobalt selenide / graphite carbon composite material, comprising the following steps:

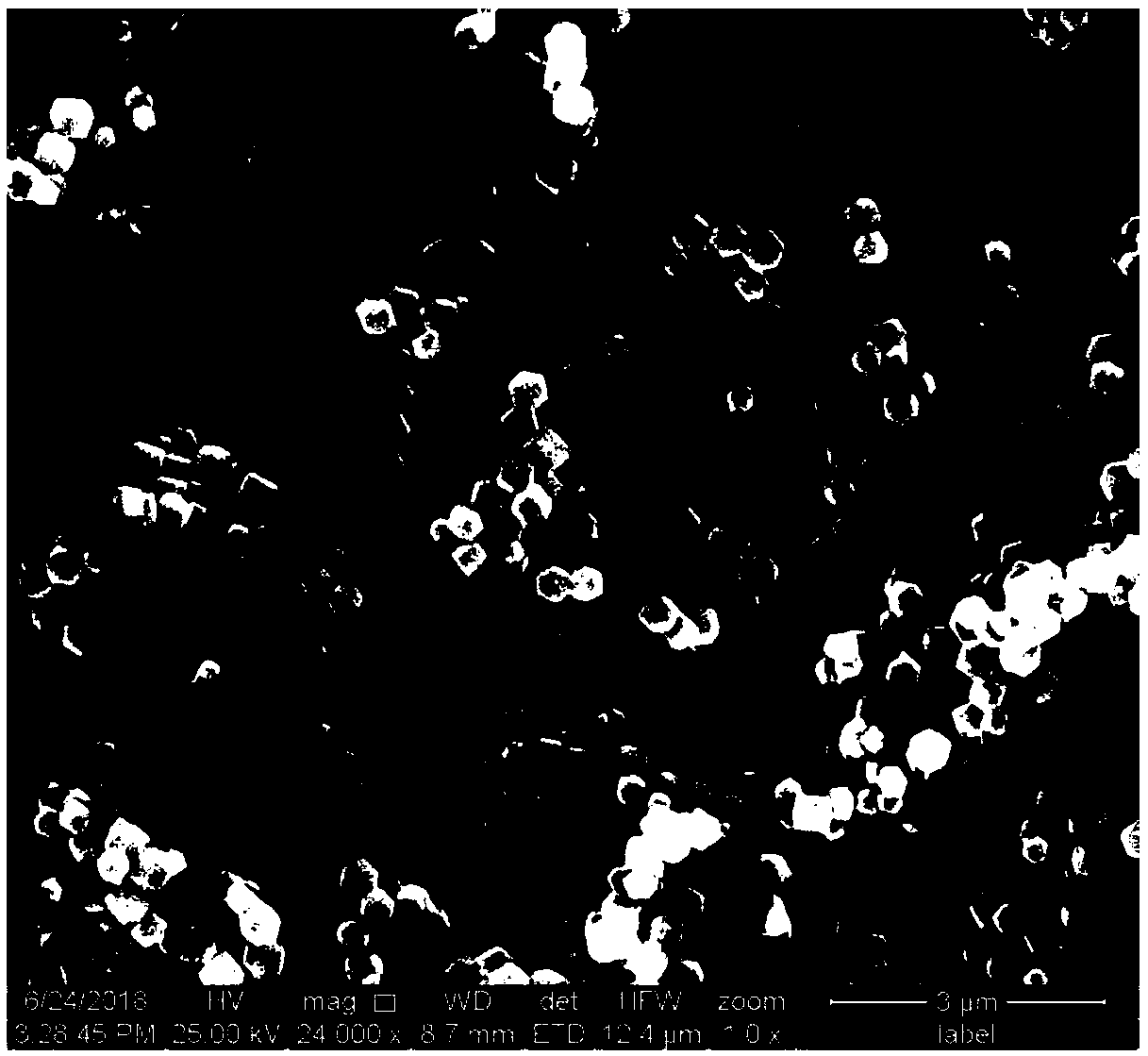

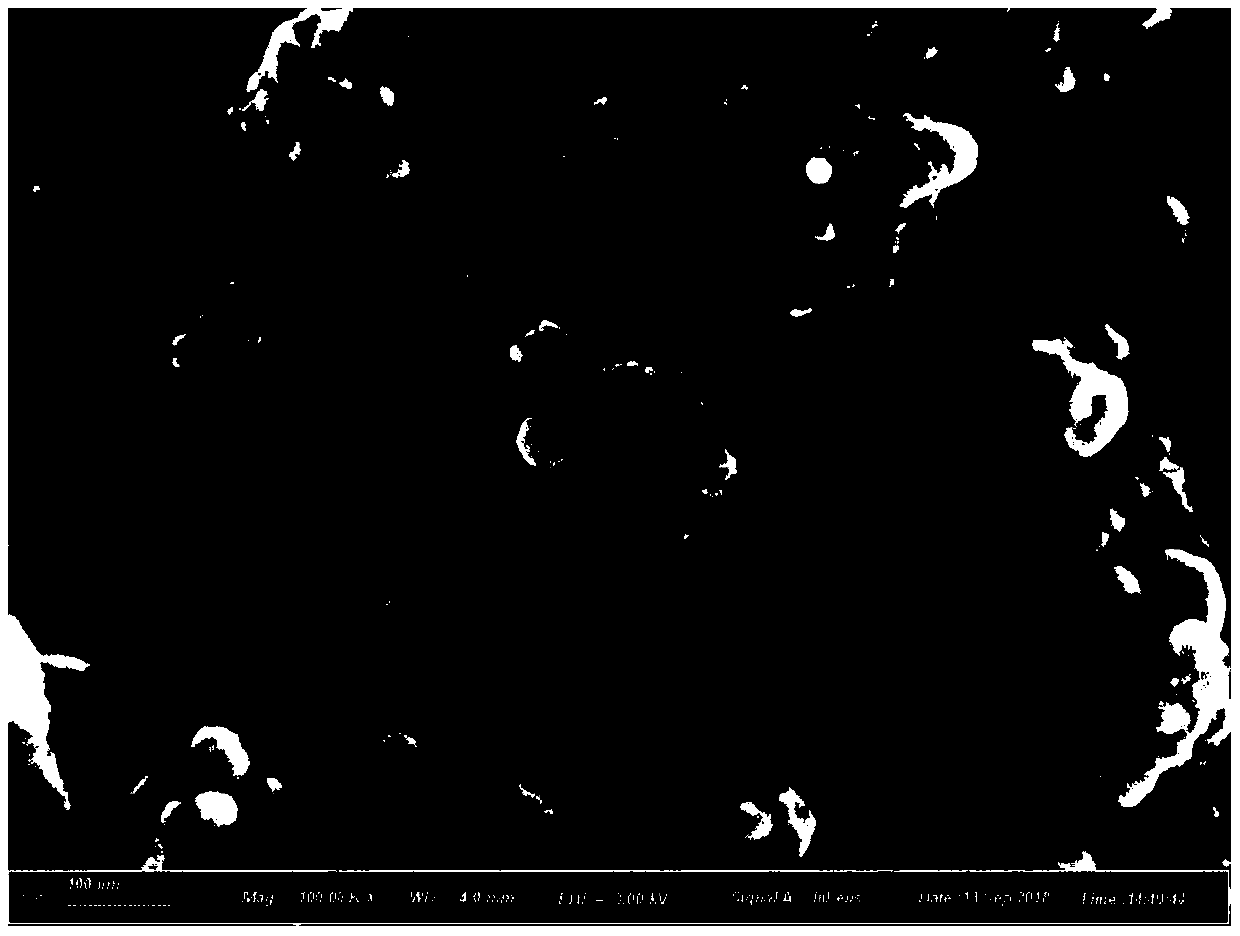

[0022] 1) Preparation of polyhedral metal-organic framework compound ZIF-67: Weigh 4.9mmol Co(NO 3 ) 2 ·6H 2 O and 39.5mmol 2-methylimidazole were dissolved in 100ml methanol respectively, and the stirring speed was set to be 350r / min. After stirring and dissolving completely, the Co(NO 3 ) 2 · 6H 2 The O solution was poured into the 2-methylimidazole solution, stirred for 12 minutes, aged at room temperature for 20 hours after the stirring was stopped, and the product was centrifuged at a speed of 15000 r / min, and the centrifugation time was 5 minutes. After centrifugation, the precipitate was washed with methanol for 3 times. The amount of methanol used was 25 times the mass of the precipitate, and then placed at 60°C for 12 hours in a vacuum. The resulting product was a polyhedral metal-organic framework compound ZIF-67. The product was blue-purple in sha...

Embodiment 2

[0026] A preparation method of cobalt selenide / graphite carbon composite material, comprising the following steps:

[0027] 1) Preparation of polyhedral metal-organic framework compound ZIF-67: Weigh 5.5mmol Co(NO 3 ) 2 ·6H 2 O and 45mmol 2-methylimidazole were dissolved in 100ml methanol respectively, and the stirring speed was set to be 350r / min. After the stirring was completely dissolved, the Co(NO 3 ) 2 · 6H 2 The O solution was poured into the 2-methylimidazole solution, stirred for 15 minutes, aged at room temperature for 22 hours after the stirring was stopped, and the product was centrifuged at a speed of 16000 r / min, and the centrifugation time was 3 minutes. After centrifugation, the precipitate was washed with methanol for 3 times. The amount of methanol used is 20 times the mass of the precipitate, and then placed at 60°C for 12 hours in a vacuum. The product obtained is a polyhedral metal-organic framework compound ZIF-67. The product is blue-purple in shape,...

Embodiment 3

[0031] A kind of preparation method of building cobalt selenide / graphite carbon composite material, comprises the following steps:

[0032] 1) Preparation of polyhedral metal-organic framework compound ZIF-67: Weigh 6mmol Co(NO 3 ) 2 ·6H 2 O and 50mmol 2-methylimidazole were dissolved in 100ml methanol respectively, and the stirring speed was set to be 350r / min. After the stirring was completely dissolved, the Co(NO 3 ) 2 · 6H 2 Pour the O solution into the 2-methylimidazole solution, stir for 20min, stop stirring and age at room temperature for 24h, centrifuge the product, the centrifuge speed is 12000r / min, centrifuge for 7min, take the centrifugal precipitate and wash it with methanol for 3 times, the amount of methanol It is 30 times the mass of the precipitate, and then placed at 60°C for 12 hours in a vacuum. The obtained product is a polyhedral metal-organic framework compound ZIF-67. The product is blue-purple in shape, rhombic dodecahedron, and the particle size i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com