Flame-retardant antibacterial master batch with metal modified cross esterification compound and preparation method of flame-retardant antibacterial master batch

A technology of metal modification and antibacterial masterbatch, which is applied in the manufacture of fire-retardant and flame-retardant filaments, rayon manufacture, chemical characteristics of fibers, etc., can solve the problems of low content of functional components and difficult to meet the needs of use, and reduce the filtration pressure. value, reduced difficulty, the effect of improving liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing a flame-retardant and antibacterial masterbatch containing a metal-modified cross-type ester compound, the specific steps are as follows:

[0053] (1) prepare cross-type esterified product;

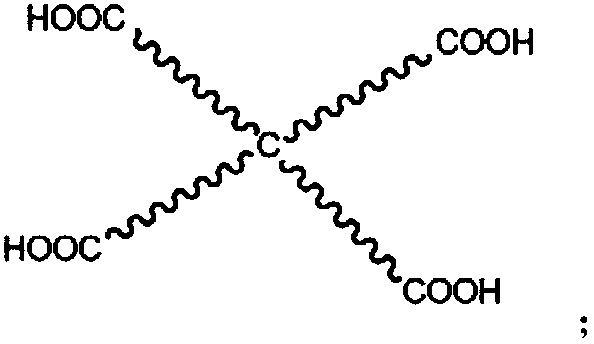

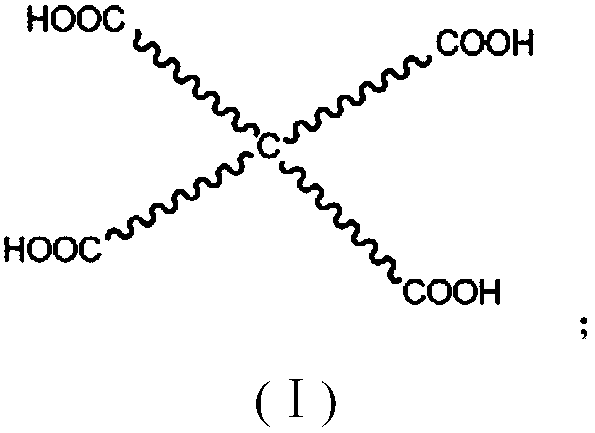

[0054] (1.1) Dibasic acid A 2 Mix with pentaerythritol at a molar ratio of 4:1, carry out melt esterification reaction under nitrogen protection and mechanical stirring at a stirring speed of 300rpm, collect the product, obtain DAPER through dissolution, filtration and drying, wherein the temperature of the melt esterification reaction is 200°C, the reaction time is 3h, A 2 The structural formula is:

[0055]

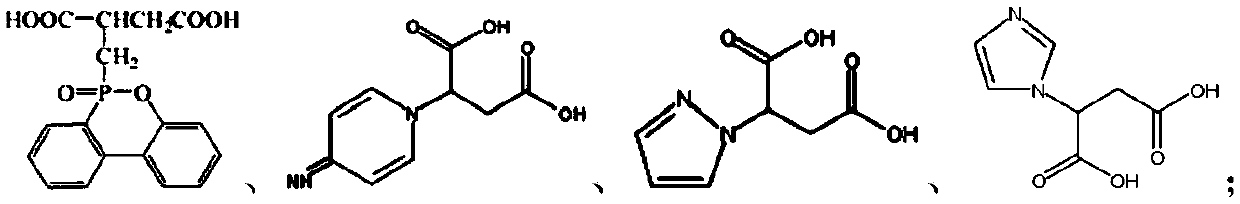

[0056] (1.2) Dibasic carboxylic acid B 2 Mix with ethylene glycol at a molar ratio of 1:1, add 4-methylbenzenesulfonic acid, and carry out melt condensation reaction under nitrogen protection and mechanical stirring at a stirring speed of 500rpm to obtain DADA, wherein B 2 The molar ratio with 4-methylbenzenesulfonic acid is 1:0.01, the temperat...

Embodiment 2

[0068] A method for preparing a flame-retardant and antibacterial masterbatch containing a metal-modified cross-type ester compound, the specific steps are as follows:

[0069] (1) prepare cross-type esterified product;

[0070] (1.1) Dibasic acid A 2 Mix with pentaerythritol at a molar ratio of 4:1, carry out melt esterification under argon protection and mechanical stirring at a stirring speed of 350rpm, collect the product, dissolve, filter and dry to obtain DAPER, wherein the melt esterification The temperature is 185°C, the reaction time is 1h, A 2 The structural formula is:

[0071]

[0072] (1.2) Dibasic carboxylic acid B 2 Mix with propylene glycol at a molar ratio of 1:1, add 4-methylbenzenesulfonic acid, and carry out melt condensation reaction under nitrogen protection and mechanical stirring at a stirring speed of 300rpm to obtain DADA, wherein B 2 The molar ratio with 4-methylbenzenesulfonic acid is 1:0.01, the temperature of the melt condensation reaction ...

Embodiment 3

[0084] A method for preparing a flame-retardant and antibacterial masterbatch containing a metal-modified cross-type ester compound, the specific steps are as follows:

[0085] (1) prepare cross-type esterified product;

[0086] (1.1) Dibasic acid A 2 Mix with pentaerythritol at a molar ratio of 4:1, carry out melt esterification under the condition of helium protection and mechanical stirring at a stirring speed of 400rpm, collect the product, obtain DAPER through dissolution, filtration and drying, wherein the melt esterification The temperature is 180°C, the reaction time is 2h, A 2 The structural formula is:

[0087]

[0088] (1.2) Dibasic carboxylic acid B 2 Mix with 1,4-butanediol at a molar ratio of 1:1, add 4-methylbenzenesulfonic acid, and carry out melt condensation reaction under argon protection and mechanical stirring at a stirring speed of 500rpm to obtain DADA, wherein B 2 The molar ratio with 4-methylbenzenesulfonic acid is 1:0.01, the temperature of me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com