Preparing method of zinc-coordination organic nano particle hybridization polyamide membrane

A nanoparticle and polyamide membrane technology, which is applied in the field of membrane separation, can solve the problems of complex synthesis and modification methods of inorganic nanoparticles, limited scale and repeated and stable preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] A method for preparing a zinc-coordinated organic nanoparticle hybrid polyamide film comprises the following steps:

[0014] 1) With polyamine as the monomer molecule, zinc nitrate hexahydrate as the metal ion compound, and dopamine as the biomimetic binder, it is configured into a water phase mixed solution, which is dip-coated on the surface of the porous support membrane, and then treated with 2-methylimidazole Aqueous solution immersion treatment, in-situ formation of zinc-containing coordination organic nanoparticles nascent film on the surface of the porous support film;

[0015] 2) Dissolving polyacyl chloride monomers in organic solvents to form an organic phase solution, dip-coating it on the surface of the nascent film loaded with zinc-coordinated organic nanoparticles to carry out interfacial cross-linking reaction, thermal curing treatment, and finally removing After washing with ion water, a hybrid polyamide membrane containing zinc-coordinated organic nano...

Embodiment 1

[0019] Take 0.2g of piperazine, 0.1g of zinc nitrate hexahydrate and 0.05g of dopamine dissolved in 100g of deionized water to form a water phase mixed solution, which is dip-coated on the surface of polysulfone ultrafiltration membrane at 15°C for 60 minutes, and then in 15 Under the temperature of 0.5% by mass percent, the 2-methylimidazole aqueous solution was dipped for 100 minutes to obtain a zinc-containing coordination organic nanoparticle nascent film, and then immersed in a 0.1% by mass percent trimesoyl chloride-n-hexane solution In the process, the interfacial crosslinking reaction was carried out at 15°C for 10 minutes, and finally cured at 45°C for 40 minutes. After washing with deionized water, a hybrid polyamide film containing zinc-coordinated organic nanoparticles was obtained.

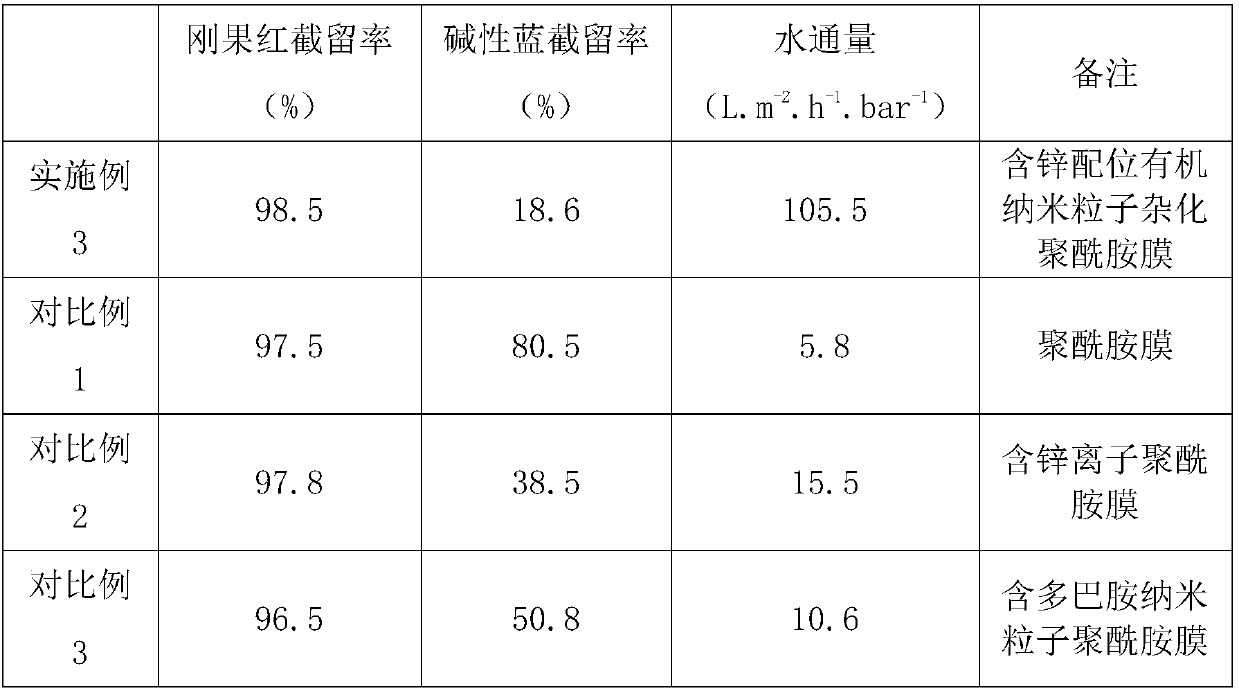

[0020] Zinc-coordinated organic nanoparticle hybrid polyamide film at 25°C, under 0.2MPa pressure, for 1g.L -1The separation result of Congo red and basic blue organic dye solution is...

Embodiment 2

[0022] Dissolve 2g of piperazine, 1g of zinc nitrate hexahydrate and 0.5g of dopamine in 100g of deionized water to form a mixed aqueous solution, dip-coat it on the surface of polysulfone ultrafiltration membrane at 25°C for 10 minutes, and then The 2-methylimidazole aqueous solution with a mass percentage concentration of 5% was dipped for 10 minutes to obtain a zinc-containing coordination organic nanoparticle nascent film, and then immersed in a 1% trimesoyl chloride n-hexane solution, The interfacial crosslinking reaction was performed at 25°C for 2 minutes, and finally cured at 65°C for 10 minutes. After washing with deionized water, a hybrid polyamide film containing zinc-coordinated organic nanoparticles was obtained.

[0023] Zinc-coordinated organic nanoparticle hybrid polyamide film at 25°C, under 0.2MPa pressure, for 1g.L -1 The separation result of Congo red and basic blue organic dye solution is: the water flux is 98.5L.m -2 .h -1 .bar -1 , the rejection rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com