Modified carbon quantum dot loaded hollow tubular carbon nitride photocatalyst and preparation method thereof

A technology of carbon quantum dots and carbon nitride, which is applied in the field of modified carbon quantum dot-supported hollow tubular carbon nitride photocatalysts and its preparation, which can solve the problem of affecting the photocatalytic performance of carbon nitride photocatalysts and limiting carbon nitride photocatalysts. Wide application, difficult to completely remove organic additives, etc., to achieve the effect of fast separation and migration rate of photogenerated carriers, good application value and application prospect, and fast separation and migration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

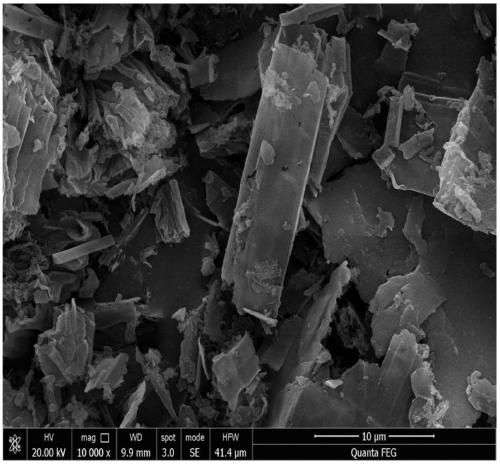

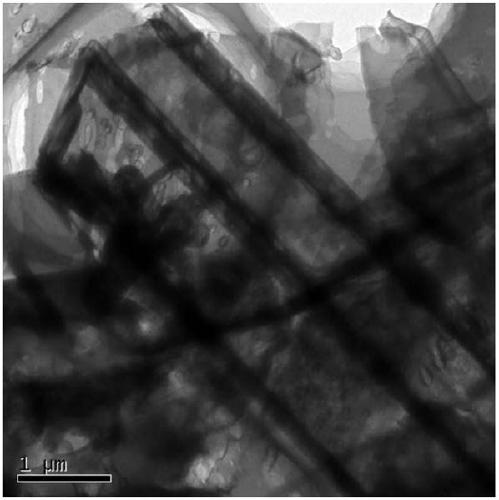

[0036] A modified carbon quantum dot-loaded hollow tubular carbon nitride photocatalyst uses hollow tubular carbon nitride as a carrier, and modified carbon quantum dots are loaded on the hollow tubular carbon nitride.

[0037] In this embodiment, the hollow tubular carbon nitride is prepared by using urea and melamine as raw materials through hydrothermal and calcination, wherein the molar ratio of urea and melamine is 3:1.

[0038] A method for preparing the modified carbon quantum dot-supported hollow tubular carbon nitride photocatalyst in the above-mentioned embodiment of the present invention, comprising the following steps:

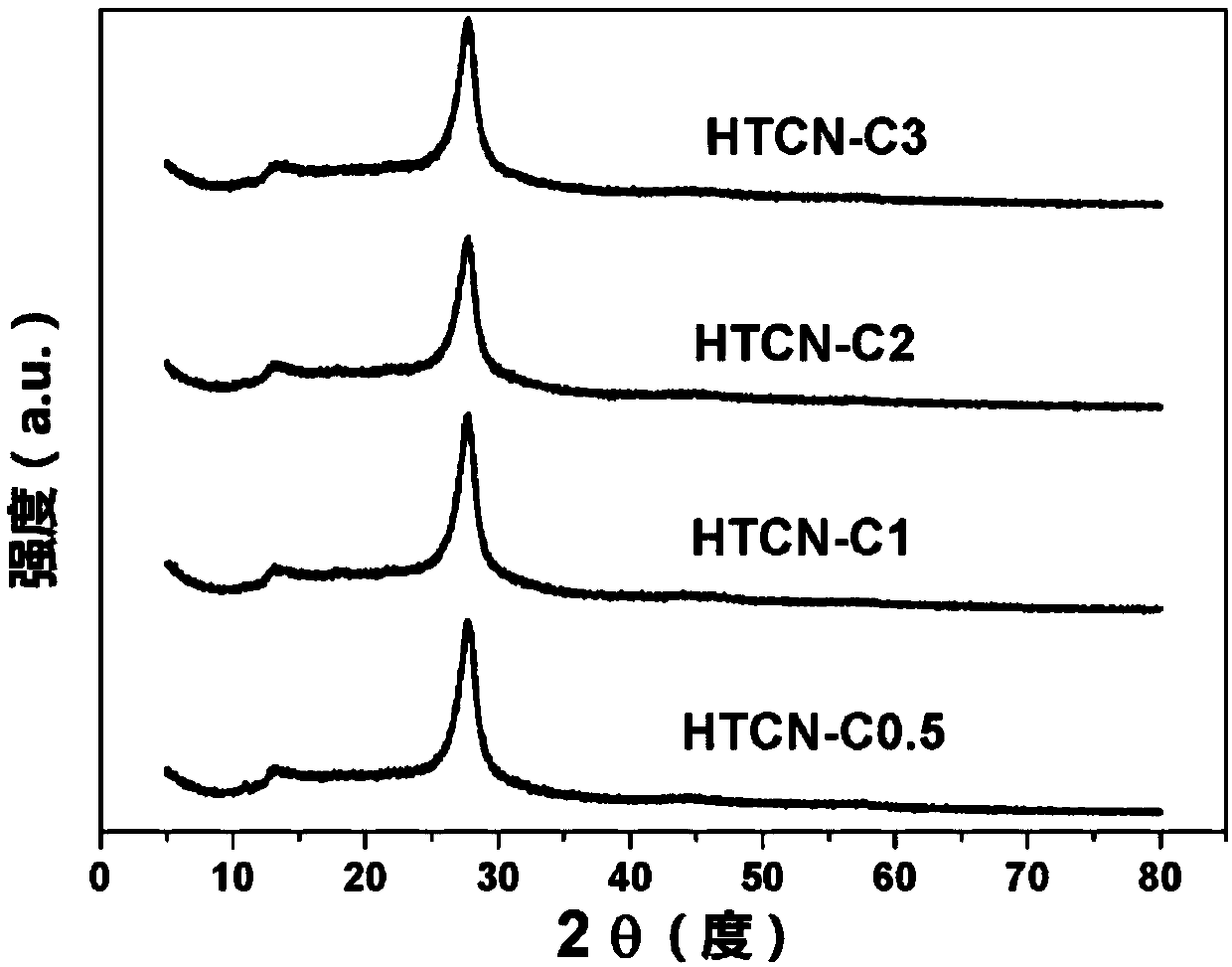

[0039] Suspend 0.2g of hollow tubular carbon nitride in 30mL of ultrapure water, add 0.5mL of modified carbon quantum dot solution, mix well, and dry at 80°C to obtain a hollow tubular carbon nitride photocatalyst supported by modified carbon quantum dots , numbered HTCN-C0.5.

[0040] In this example, the hollow tubular carbon nitride used is pre...

Embodiment 2

[0048] A method for preparing a modified carbon quantum dot-supported hollow tubular carbon nitride photocatalyst is basically the same as that of the modified carbon quantum dot-supported hollow tubular carbon nitride photocatalyst in Example 1, the only difference being: Example 2 The volume of the modified carbon quantum dot solution is 1 mL.

[0049] The modified carbon quantum dot-loaded hollow tubular carbon nitride photocatalyst prepared in Example 2 is designated as HTCN-C1.

Embodiment 3

[0051] A method for preparing a modified carbon quantum dot-supported hollow tubular carbon nitride photocatalyst is basically the same as that of the modified carbon quantum dot-supported hollow tubular carbon nitride photocatalyst in Example 1, the only difference being: Example 3 The volume of the modified carbon quantum dot solution is 2mL.

[0052] The modified carbon quantum dot-loaded hollow tubular carbon nitride photocatalyst prepared in Example 3 is designated as HTCN-C2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com