Nano core-shell compound and composite fiber membrane for photothermal enhanced degradation of chemical warfare agent simulants and preparation methods and application of nano core-shell compound and composite fiber membrane

A composite fiber membrane and nano-core-shell technology, which is applied in the field of catalytic chemistry, can solve the problems of complex and harsh fiber membrane preparation methods, unfavorable practical use of catalysts, and difficulty in achieving scale, so as to solve the problems of reduced catalytic performance, long-term challenges, and improved The effect of catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A method for preparing a nano-core-shell compound of photothermally enhanced degradation chemical warfare agent simulants, the steps are as follows:

[0071] (1) Preparation of photothermal agent

[0072] Mix and stir 90mL water, 40mL ethanol and 2mL ammonia water for 30min to obtain a mixed solution. Weigh 0.5g dopamine hydrochloride and dissolve it in 10mL water and add it to the mixed solution. Stir continuously at 30°C for 24h. Washing with water three times to obtain the photothermal agent dopamine melanin nanoparticles (Dpa NPs);

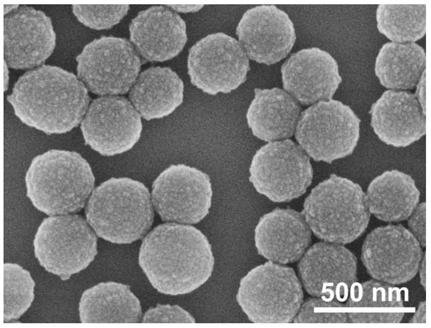

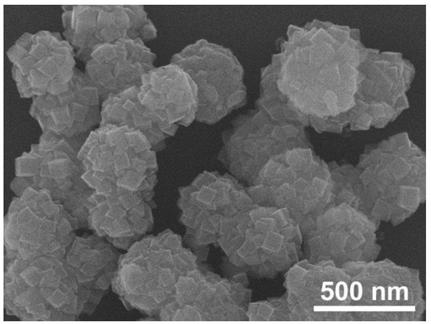

[0073] (2) Preparation of nano-core-shell composites

[0074] Weigh 7 mg of Dpa NPs in step (1) and disperse them in 50 mL of N,N-dimethylformamide, add 1.3 mmol of zirconium chloride, stir at room temperature for 5 h to obtain a dispersion, the purpose is to adsorb zirconium ions on the surface of Dpa NPs ; Add 1.3mmol 2-aminoterephthalic acid to the dispersion, stir at room temperature for 1 hour, put the dispersion into the reactio...

Embodiment 2

[0084] A method for preparing a composite fiber membrane that photothermally enhances and degrades chemical warfare agent simulants, the steps are as follows:

[0085] (1) Preparation of spinning solution

[0086] 0.6g of Dpa@UiO-66-NH prepared in Example 1 2 Disperse evenly in 3.6g N,N-dimethylformamide solution, then add 0.4g polyacrylonitrile and stir for 12h, mix uniformly to obtain spinning solution; wherein the weight average molecular weight of polyacrylonitrile is 150000;

[0087] (2) Preparation of composite fiber membrane

[0088] Electrospinning the spinning solution obtained in step (1), the spinning conditions are: spinning voltage 16kV, electrode distance 180mm, temperature 30°C, relative humidity 10%, to obtain a composite fiber membrane, namely Dpa@UiO-66 -NH 2 / PAN.

[0089] The composite fiber membrane Dpa@UiO-66-NH prepared in this example 2 / SEM picture of PAN Figure 9 As shown, the diameter of the fiber is 0.5-3 μm.

[0090] The composite fiber mem...

experiment example 1

[0112] The product that embodiment 1 and comparative example 1-2 obtains carries out the degradation experiment to chemical warfare agent simulant dimethoxychlor (DMNP) respectively under the condition of not adding near-infrared laser and adding near-infrared laser, and concrete steps are as follows: room temperature 6.7-7.7 mg of the above powder sample and 1 mL of 0.45 M N-ethylmorpholine aqueous solution were vigorously stirred in a 7 mL quartz test tube for 30 min, and then the test tubes were placed in a dark box with a near-infrared laser and without a light source, and Circulating water was placed around it to keep the temperature at 25°C. Add 4 μL of DMNP to the above mixture and continue to stir, take out 20 μL of the solution at intervals and dilute it in 0.15M N-ethylmorpholine aqueous solution, and detect the absorbance of each sample with a UV-visible spectrophotometer to obtain the following: Figure 16-18 The conversion curve of DMNP is shown.

[0113] Depend ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com