Porous slow-release carbon filler and preparation method and application thereof

A slow-release and zeolite technology, which is applied in the field of water treatment, can solve problems such as water distribution, gas distribution is not easy to be uniform, unfavorable microbial film growth, and does not meet the process requirements, etc., to achieve the reduction of external carbon sources, low price, and high compressive strength increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Raw material preparation: zeolite, cement, walnut shell and aluminum are all made into powder;

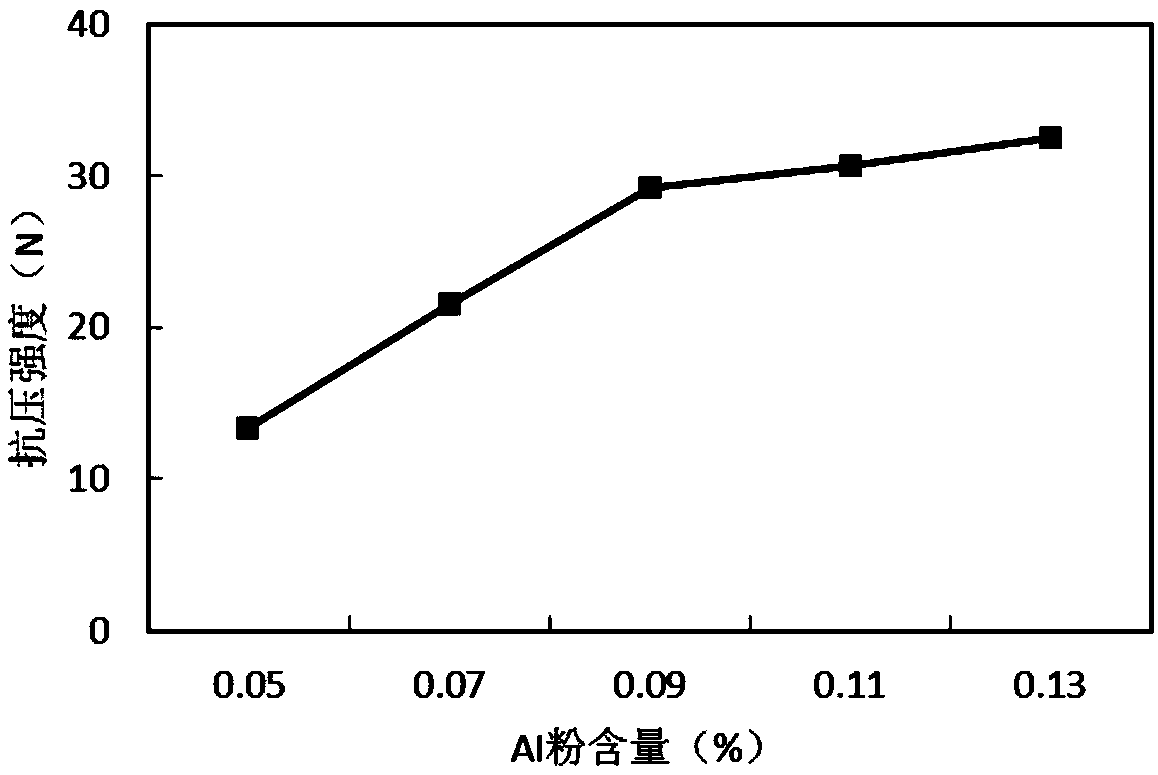

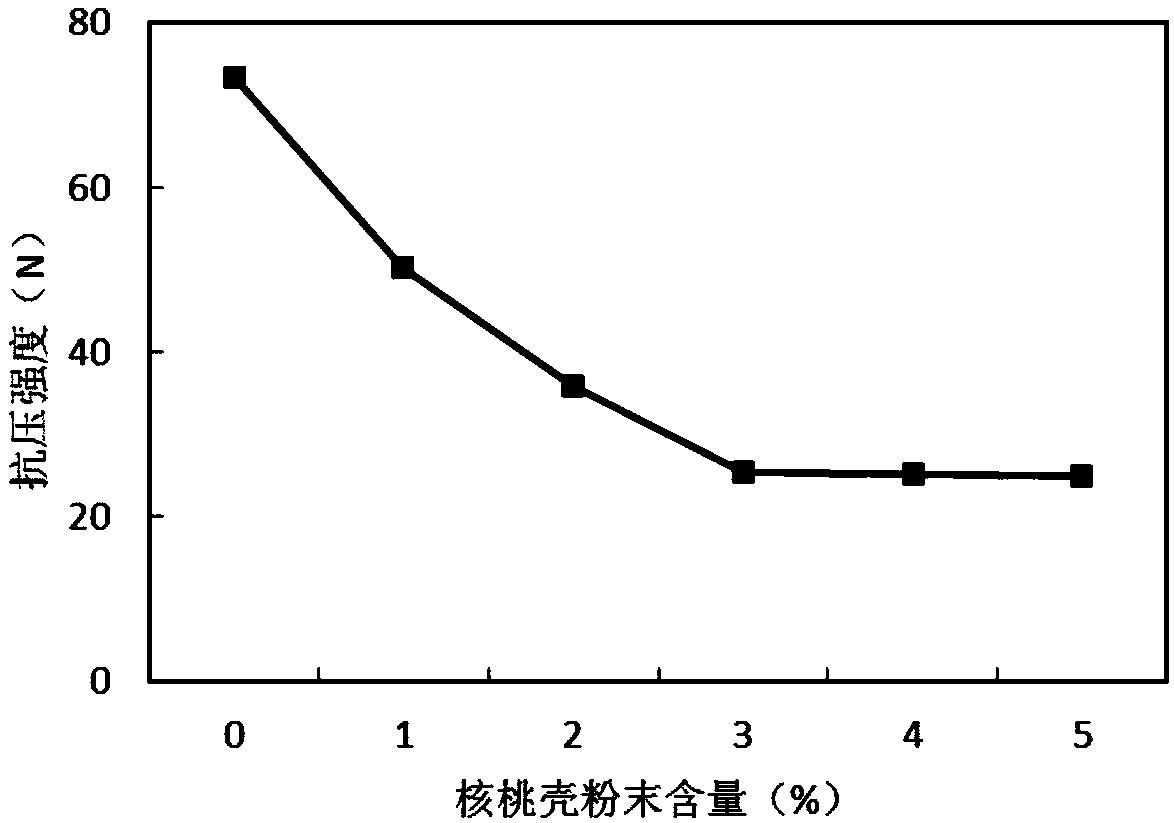

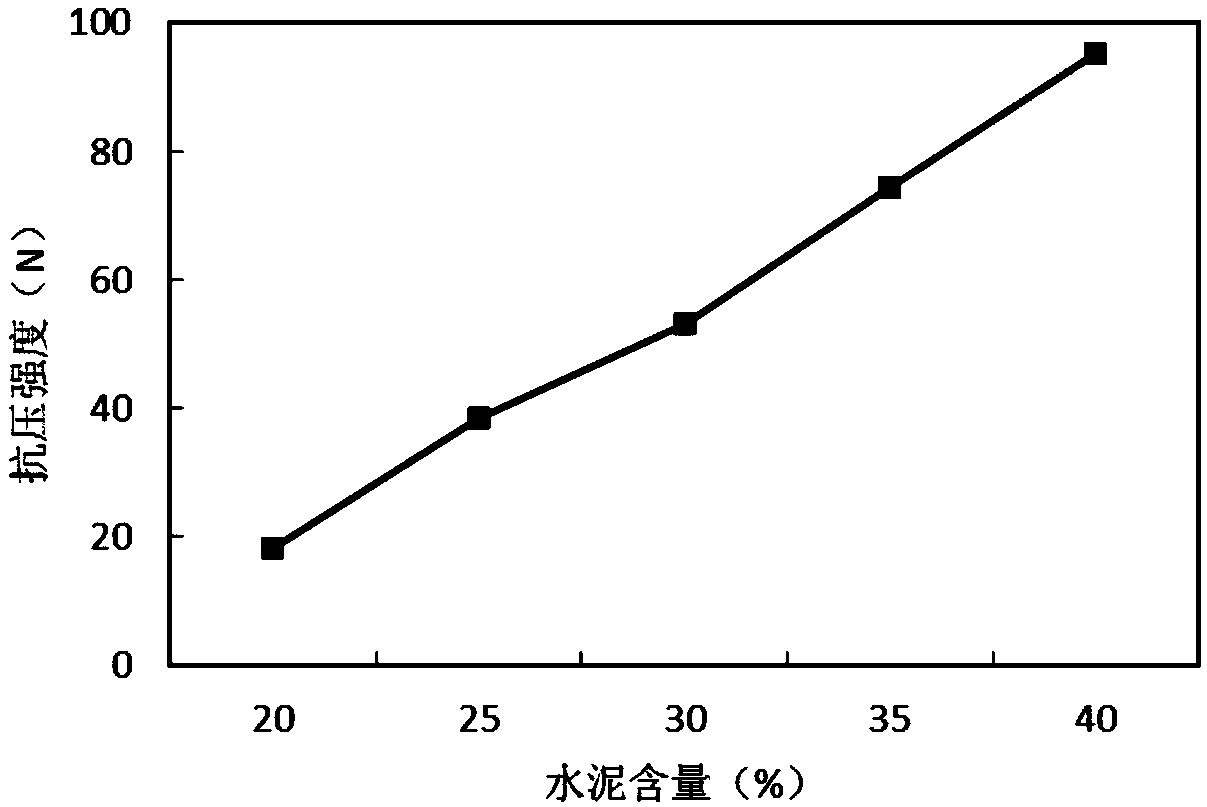

[0058] (2) Stirring and granulation: The powder is mixed according to the mass ratio of zeolite powder: cement powder: walnut shell powder: aluminum powder = 100:30:1:0.05, and stir for 10min with a mixer, then add water Mix them, pass the pelletizing machine into strips, and finally press them into 6mm spherical particles;

[0059] (3) Curing: Curing the prepared spherical particles under natural conditions, spraying water every day for curing, and each time the surface of the spherical particles is soaked with water, the curing is successful after 12 days of curing, that is, the porous slow-release carbon filler is successfully prepared.

[0060] The compressive strength of the prepared porous slow-release carbon filler was measured. Small balls of uniform size were randomly selected, and the compressive strength was measured with the servo material multifunctional high and l...

Embodiment 2

[0062] (1) Raw material preparation: zeolite, cement, walnut shell and aluminum are all made into powder;

[0063] (2) Stirring and granulating: The powder is mixed according to the mass ratio of zeolite powder: cement powder: walnut shell powder: aluminum powder = 100:30:2:0.07, and stir for 20 minutes with a mixer, then add water Mix them, pass the pelletizing machine into strips, and finally press them into 7mm spherical particles;

[0064] (3) Curing: Curing the prepared spherical particles under natural conditions, spraying water every day for curing, and each time the surface of the spherical particles is soaked with water, the curing is successful after 12 days of curing, that is, the porous slow-release carbon filler is successfully prepared.

[0065] The compressive strength of the prepared porous slow-release carbon filler was measured. Small balls of uniform size were randomly selected, and the compressive strength was measured with the servo material multifunctional high ...

Embodiment 3

[0067] (1) Raw material preparation: zeolite, cement, walnut shell and aluminum are all made into powder;

[0068] (2) Stirring and granulation: The powder is mixed according to the mass ratio of zeolite powder: cement powder: walnut shell powder: aluminum powder = 100:30:3:0.09, and stir for 10 minutes with a mixer, then add water Mix them, pass the pelletizing machine into strips, and finally press into 8mm spherical particles;

[0069] (3) Curing: Curing the prepared spherical particles under natural conditions, spraying water every day for curing, and each time the surface of the spherical particles is soaked with water, the curing is successful after 12 days of curing, that is, the porous slow-release carbon filler is successfully prepared.

[0070] The compressive strength of the prepared porous slow-release carbon filler was measured. Small balls of uniform size were randomly selected, and the compressive strength was measured with the servo material multifunctional high and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com