High-performance fireproof composite sheet material and preparation method thereof

A composite board, high-performance technology, applied in the direction of chemical instruments and methods, non-polymer adhesive additives, adhesive types, etc., can solve problems such as delamination, cracking, etc., to achieve not easy to crack, excellent fire resistance, good The effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

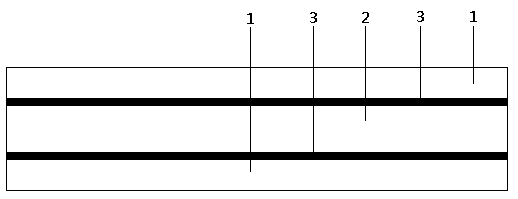

Image

Examples

Embodiment 1

[0032] A method for preparing a high-performance fireproof composite board, comprising the following steps:

[0033] (1) Preparation of component A of the adhesive

[0034] 80 parts of modified phenolic resin, 80 parts of modified epoxy resin, 40 parts of nitrile, 40 parts of polyvinyl butyral, 40 parts of silane coupling agent, 5 parts of inorganic fireproof fiber, 2 parts of hollow microspheres, expansion 2 parts of vermiculite, mixed uniformly in a kneader to obtain component A of the gel-like adhesive.

[0035] Among them, the modified phenolic resin uses sodium hydroxide as a catalyst, reacts in an alkaline medium, uses phenol and formaldehyde as raw materials, and is prepared by a conventional preparation process. The synthesized modified phenolic resin has a high ortho structure. The modified epoxy resin was prepared by the following method: 20 parts by weight of isocyanate-terminated prepolymer and 10 parts of aromatic amine curing agent were added to 80 parts by weig...

Embodiment 2

[0045] A method for preparing a high-performance fireproof composite board, comprising the following steps:

[0046] (1) Preparation of component A of the adhesive

[0047] 100 parts of modified phenolic resin, 100 parts of modified epoxy resin, 60 parts of nitrile, 50 parts of polyvinyl butyral, 50 parts of silane coupling agent, 10 parts of inorganic fireproof fiber, 5 parts of hollow microspheres, expansion 5 parts of vermiculite were uniformly mixed in a kneader to obtain component A of the gel-like adhesive.

[0048] Among them, the modified phenolic resin is prepared by using sodium hydroxide as a catalyst, using phenol and formaldehyde as raw materials, reacting in an alkaline medium, and adopting a conventional preparation process. The synthesized modified phenolic resin has a high ortho structure. The modified epoxy resin was prepared by the following method: 30 parts by weight of isocyanate-terminated prepolymer and 15 parts of aromatic amine curing agent were added...

Embodiment 3

[0058] A method for preparing a high-performance fireproof composite board, comprising the following steps:

[0059] (1) Preparation of component A of the adhesive

[0060] 90 parts of modified phenolic resin, 90 parts of modified epoxy resin, 50 parts of nitrile, 45 parts of polyvinyl butyral, 45 parts of silane coupling agent, 7 parts of inorganic fireproof fiber, 3 parts of hollow microsphere, expansion 3 parts of vermiculite, mixed uniformly in a kneader to obtain component A of the gel-like adhesive.

[0061] Among them, the modified phenolic resin is prepared by using sodium hydroxide as a catalyst, using phenol and formaldehyde as raw materials, reacting in an alkaline medium, and adopting a conventional preparation process. The synthesized modified phenolic resin has a high ortho structure. The modified epoxy resin was prepared by the following method: 25 parts by weight of isocyanate-terminated prepolymer and 13 parts of aromatic amine curing agent were added to 85 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com