An electrode resistance reducing agent for resistivity detection

A technology of resistivity method and resistance reducing agent, applied in the field of electrode resistance reducing agent and its corresponding devices, can solve the problems of unstable effective conductive components, reducing grounding resistance, poor geological detection, etc., to achieve enhanced conductivity and lower resistivity , The effect of strong water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

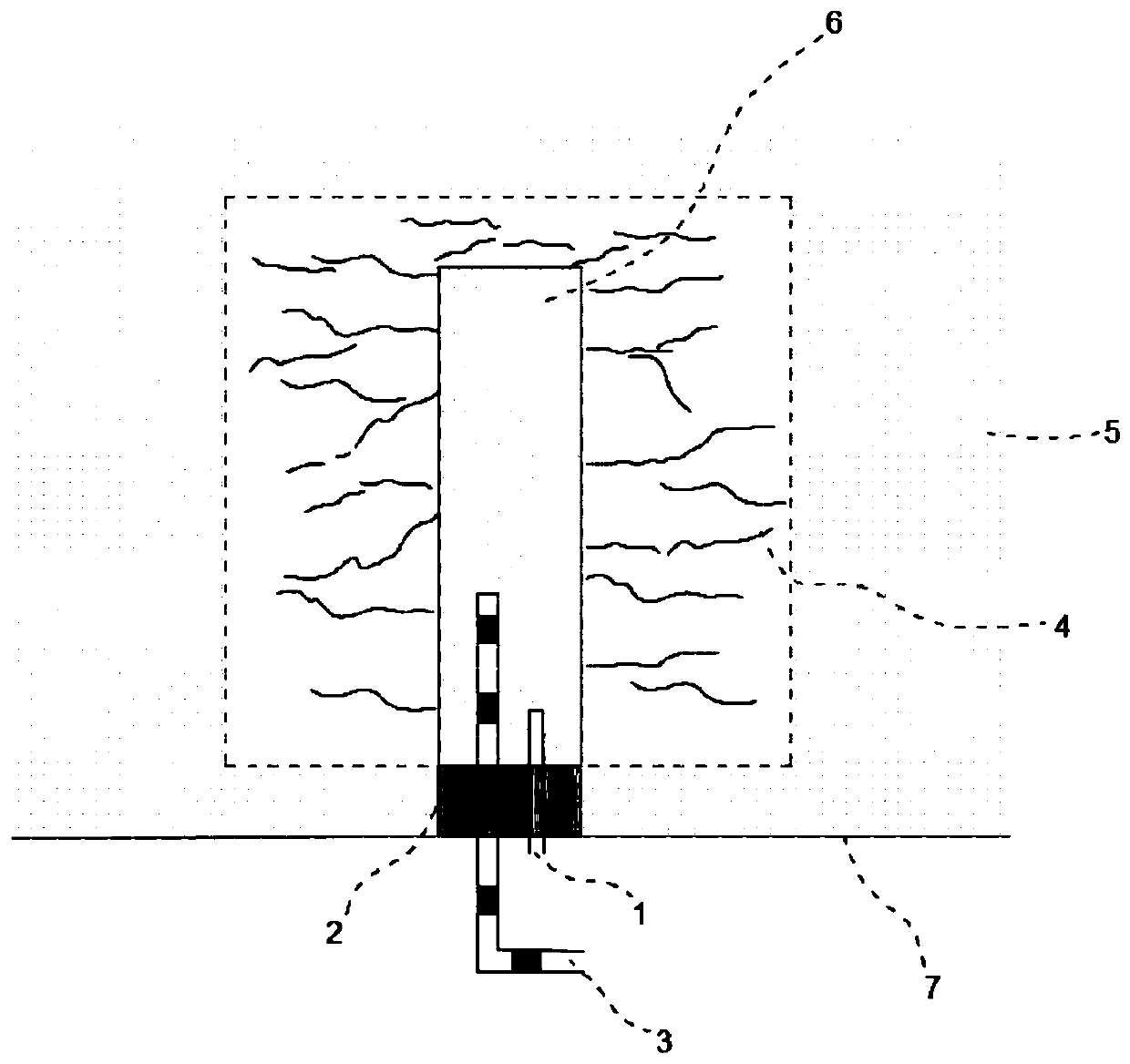

Image

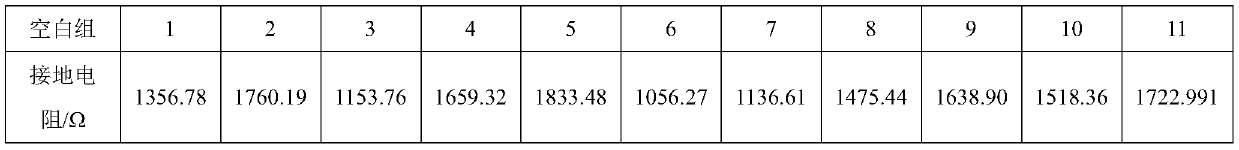

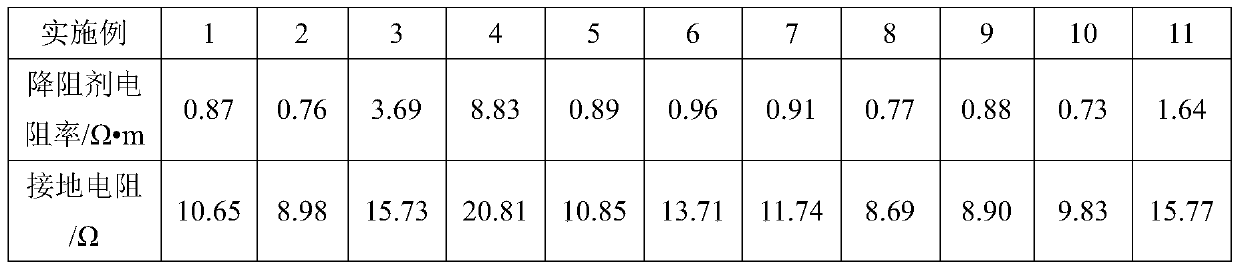

Examples

Embodiment 1

[0042] A preparation method for an electrode resistance reducing agent for resistivity method detection, comprising the steps of:

[0043] (1) Add 30% calcium-based bentonite and 10% sodium chloride into water, and stir to obtain a mixed solution;

[0044] (2) add 8% carbon fiber, 8% stainless steel fiber, 5% zinc powder, 5% aluminum powder, 5% copper powder in the mixed solution that step (1) obtains, mix homogeneously, for subsequent use; Described carbon fiber, stainless steel fiber The aspect ratio is about 1000-1300, 400-700, and the particle sizes of the zinc powder, aluminum powder, and copper powder are respectively between 0.2-0.5 μm, 5-8 μm, and 5-8 μm;

[0045] (3) In the mixture of step (2), continue to add 20% conductive cement, 4% plaster of paris and 5% copper sulfate, after mixing evenly, adjust the water content to between 40wt.%. Electrode resistance reducer.

experiment example 1

[0047] An electrode resistance reducing agent used for resistivity method detection, its preparation method is the same as that of Example 1, the difference is that: in terms of mass percentage, the resistance reducing agent includes the following components: 30% sodium bentonite, 8% carbon fiber, Stainless steel fiber 8%, zinc powder 5%, aluminum powder 5%, copper powder 5%, sodium chloride 10%, copper sulfate 5%, conductive cement 20%, plaster of paris 4%.

Embodiment 2

[0049] A preparation method for an electrode resistance reducing agent for resistivity method detection, comprising the steps of:

[0050] (1) Add 30% calcium-based bentonite and 9% sodium chloride into water, and stir to obtain a mixed solution;

[0051] (2) add 10% carbon fiber, 10% stainless steel fiber, 10% zinc powder, 8% aluminum powder, 8% copper powder in the mixed solution that step (1) obtains, mix homogeneously, for subsequent use; Described carbon fiber, stainless steel fiber The aspect ratio is about 1200-1500, 500-800, and the particle diameters of the zinc powder, aluminum powder, and copper powder are respectively between 0.2-0.5 μm, 8-10 μm, and 8-10 μm;

[0052] (3) In the mixture of step (2), continue to add 10% conductive cement, 5% plaster of paris and 4% copper sulfate, and after mixing evenly, adjust the water content to between 45wt.%. Electrode resistance reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com