Lead-free and nickel-free environment-friendly glasses copper needle

A technology of glasses and copper needles, applied in glasses/goggles, optics, instruments, etc., can solve problems such as human health hazards, and achieve the effect of not easy to wear and bright metal texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

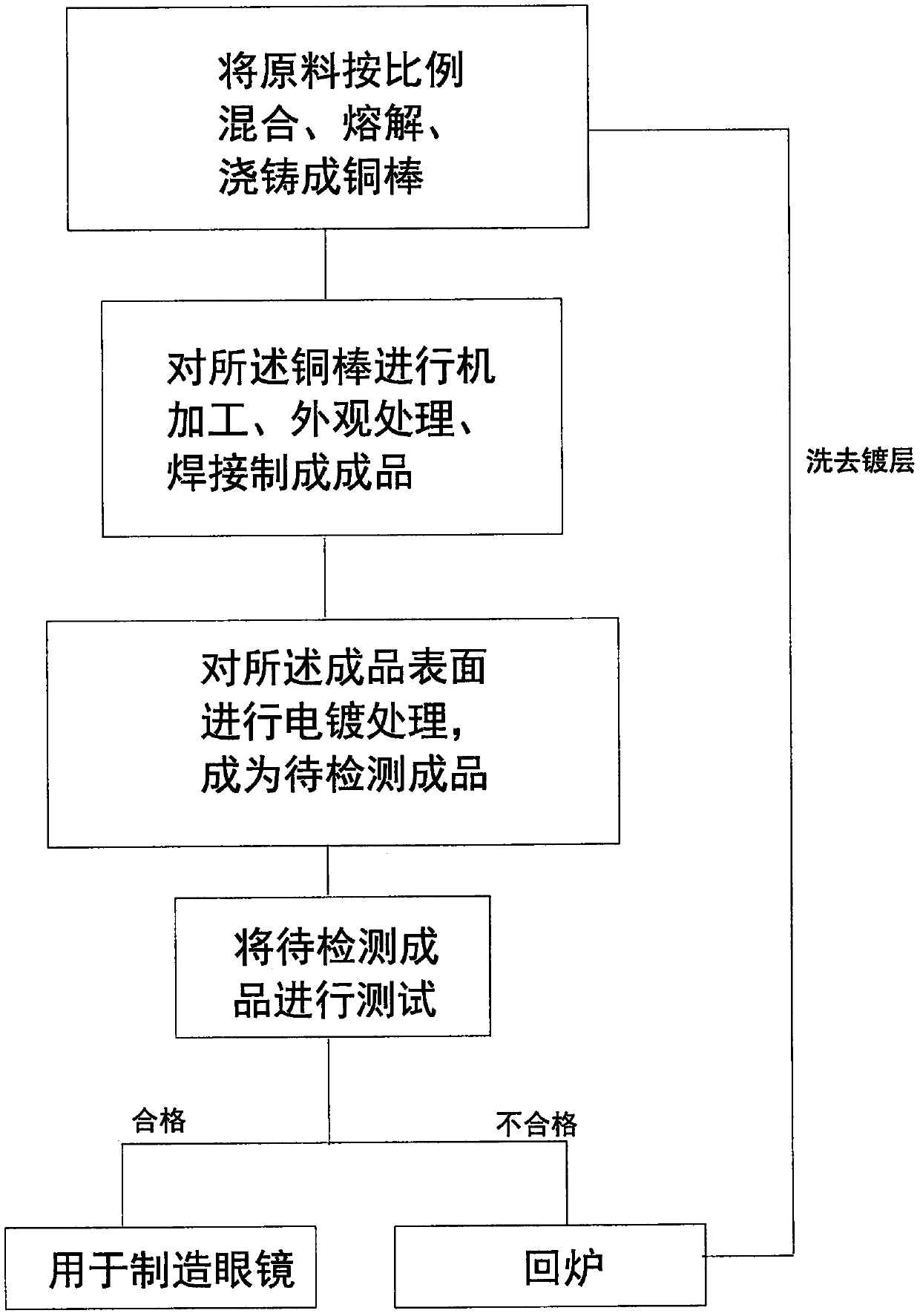

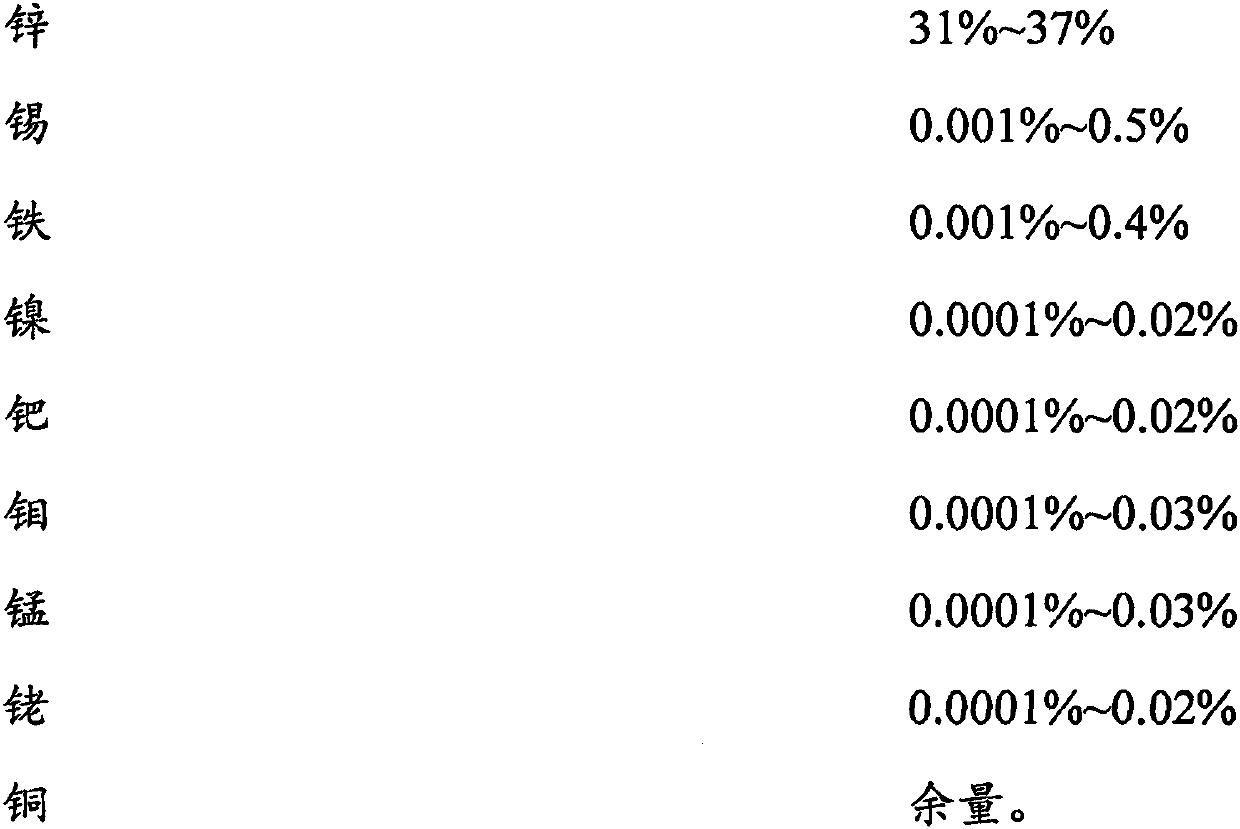

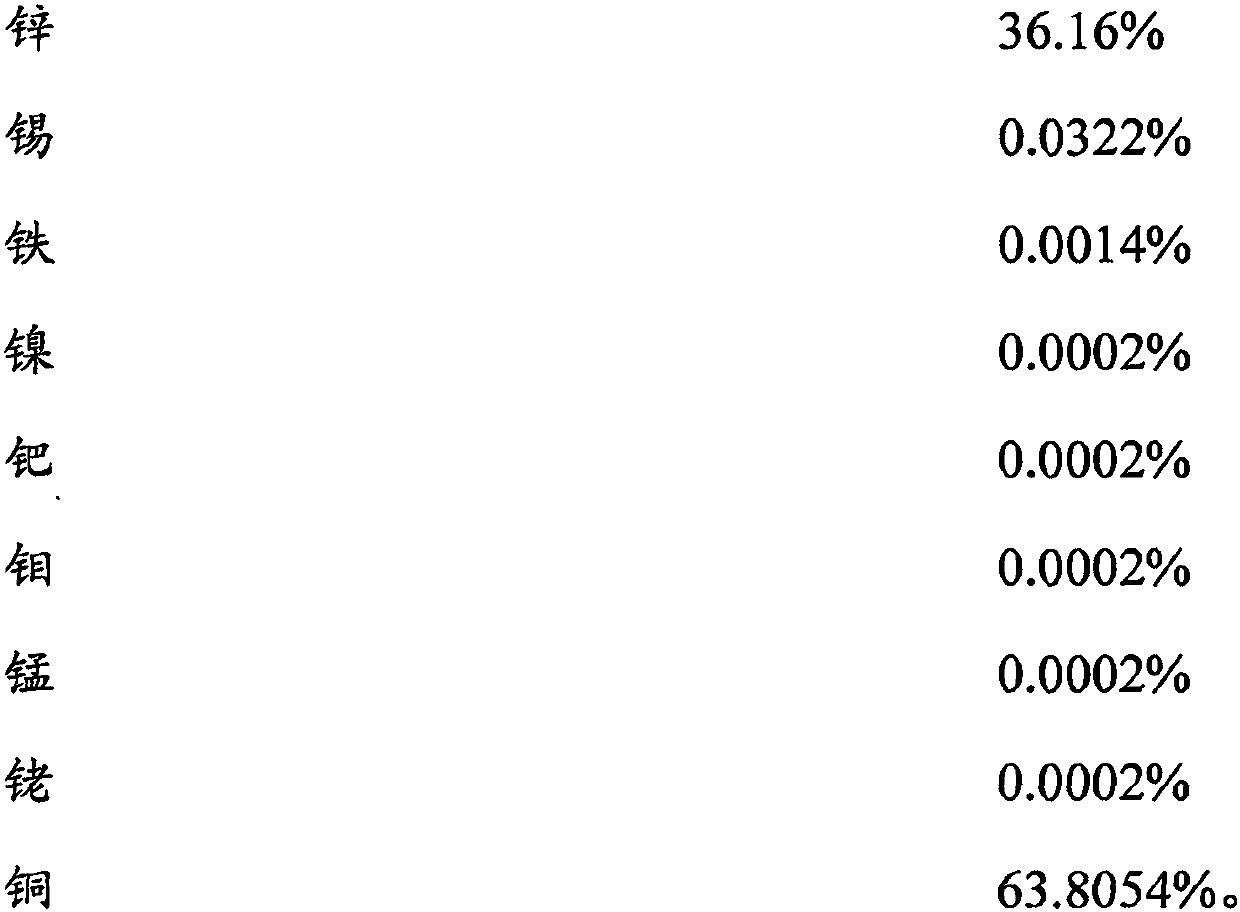

[0031] This embodiment provides a kind of lead-free and nickel-free environmental protection glasses copper needle, as figure 1 As shown, for the manufacture of the straight body glasses copper needle with simple structure, first take 63805.4g pure copper, 36160g zinc, 32.2g tin, 1.4g iron, 0.2g nickel, 0.2g palladium, 0.2g molybdenum, 0.2g manganese, Add 0.2g of rhodium into the melting furnace, use electric heating to heat the temperature to 1100°C until the metal is completely melted, pour the copper liquid into the pre-prepared mold to make a copper rod with a diameter of 6mm, and use extrusion The mold extrudes and draws the cooled copper rod into a copper wire with a diameter of 1.5mm and cuts it into a 120mm long copper wire. The copper wire is milled out with a milling cutter according to the specifications, and a pusher is used to punch a hole at one end of the copper wire. The grinder sharpens the other end of the copper wire to obtain a copper needle, and then uses ...

Embodiment 2

[0052] This embodiment provides a kind of lead-free and nickel-free environmental protection glasses copper needle, as figure 1 As shown, for the manufacture of combined glasses copper needle with complex structure, 63375.8g pure copper, 36160g zinc, 237.6g tin, 182.4g iron, 0.2g nickel, 16g palladium, 9g molybdenum, 5g manganese, 14g rhodium are used as special yellow The raw material of copper is obtained through the same processing steps as in Example 1 to obtain the parts of the combined copper needle, and the parts of the processed copper needle are welded together by an arc welding machine, and then through the same follow-up treatment as in Example 1 to obtain Copper pins for glasses.

[0053] In the copper needle for lead-free and nickel-free environment-friendly glasses provided in this embodiment, the structure of the copper needle is relatively complex, and it is a combined type, which requires high mechanical properties of special brass materials, and needs to have...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com