Sea urchin shaped hollow structure nickel, copper and selenium ternary nanometer catalytic material and preparation method and application thereof

A nano-catalytic material, hollow structure technology, applied in the preparation of amino compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of low reporting of copper and nickel selenide, etc., and achieve the effect of good catalytic hydrogenation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

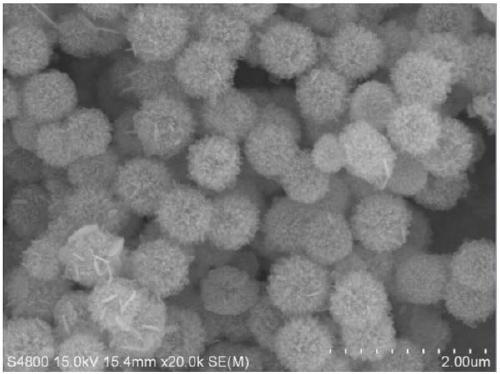

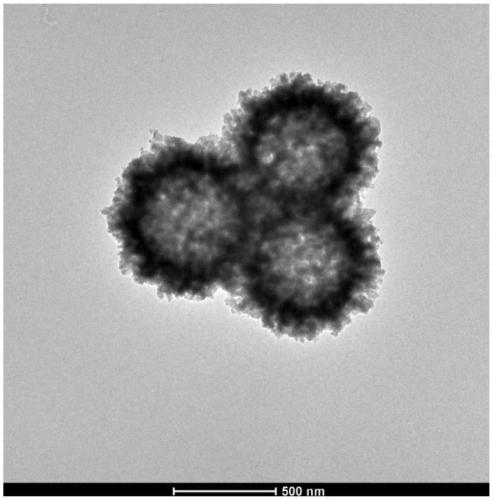

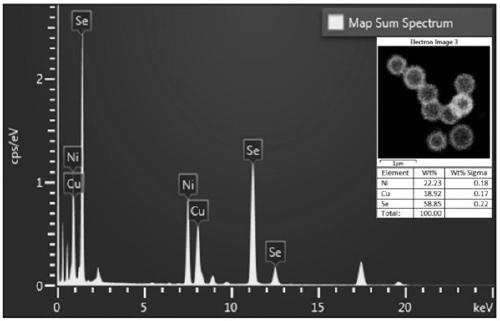

[0036] A nickel-copper-selenide ternary nano-catalysis material with a sea urchin-shaped hollow structure has a sea urchin-shaped hollow structure, and the diameter of the nickel-copper-selenium ternary nano-material with the structure is 400-600 nanometers.

[0037] A method for preparing a sea urchin-shaped hollow structure nickel-copper-selenium ternary nano-catalyst material, the steps comprising:

[0038] A. Prepare the precursor of the sea urchin-shaped hollow structure nickel-copper-selenium ternary nanocatalytic material by solvothermal method: at room temperature, dissolve 2.4g copper nitrate trihydrate and 2.9g nickel nitrate hexahydrate in 200ml water and 100ml ethylene glycol Add 6.0g urea and 5.0g polyvinylpyrrolidone (K:30) to the mixed solution, stir and mix well, place in a 500ml polytetrafluoroethylene reactor lining, then place the polytetrafluoroethylene reactor lining Put it into a steel sleeve and tighten it, react at 80°C for 10 hours, naturally cool to r...

Embodiment 2

[0041] A nickel-copper-selenide ternary nano-catalysis material with a sea urchin-shaped hollow structure has a sea urchin-shaped hollow structure, and the diameter of the nickel-copper-selenium ternary nano-material with the structure is 200-600 nanometers.

[0042] A method for preparing a sea urchin-shaped hollow structure nickel-copper-selenium ternary nano-catalyst material, the steps comprising:

[0043] A. Prepare the precursor of the sea urchin-shaped hollow structure nickel-copper-selenide ternary nanocatalytic material by solvothermal method: at room temperature, dissolve 2.9g copper nitrate trihydrate and 3.5g nickel nitrate hexahydrate in 150ml water and 150ml ethylene glycol Add 6.0g urea and 12.0g polyvinylpyrrolidone (K:60) to the mixed solution, stir and mix well, place in a 500ml polytetrafluoroethylene reactor lining, then place the polytetrafluoroethylene reactor lining Put it into a steel sleeve and tighten it, react at 70°C for 18 hours, naturally cool to ...

Embodiment 3

[0046] A nickel-copper-selenide ternary nano-catalysis material with a sea urchin-shaped hollow structure has a sea urchin-shaped hollow structure, and the diameter of the nickel-copper-selenium ternary nano-material with the structure is 200-600 nanometers.

[0047] A method for preparing a sea urchin-shaped hollow structure nickel-copper-selenium ternary nano-catalyst material, the steps comprising:

[0048] A. Prepare the precursor of the sea urchin-shaped hollow structure nickel-copper-selenide ternary nanocatalytic material by solvothermal method: at room temperature, dissolve 2.4g copper nitrate trihydrate and 2.9g nickel nitrate hexahydrate in 60ml water and 240ml ethylene glycol Add 6.0g of urea and 3.0g of polyvinylpyrrolidone (K:25) to the mixed solution, stir and mix evenly, place in a 500ml polytetrafluoroethylene reactor lining, then place the polytetrafluoroethylene reactor lining Put it into a steel sleeve and tighten it, react at 100°C for 6 hours, naturally co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com