Magnetic cobalt carbon attapulgite composite material and its preparation method and application

A technology of attapulgite and composite materials, applied in the preparation of organic compounds, preparation of aminohydroxy compounds, chemical instruments and methods, etc., can solve problems such as waste of attapulgite resources, secondary pollution, secondary pollution of water bodies, etc. Good catalytic hydrogenation performance, enhanced stability, and the effect of increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

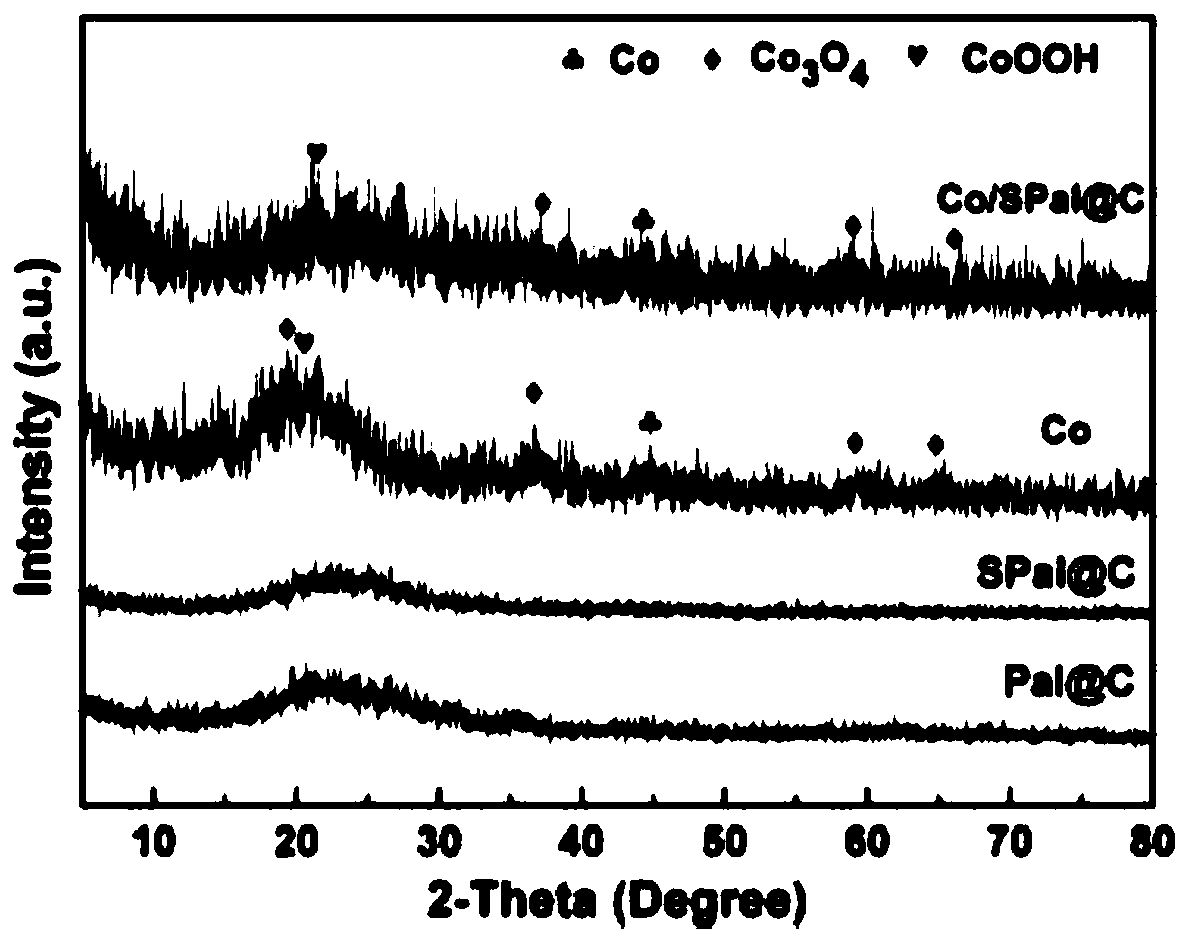

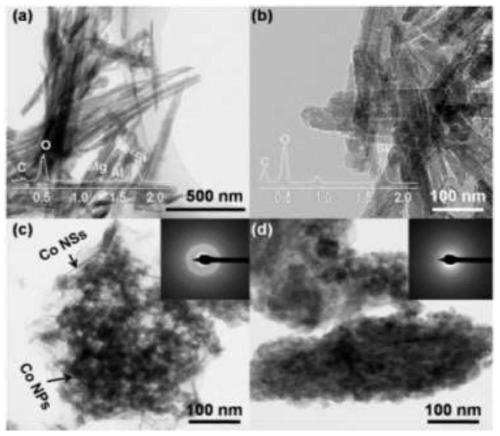

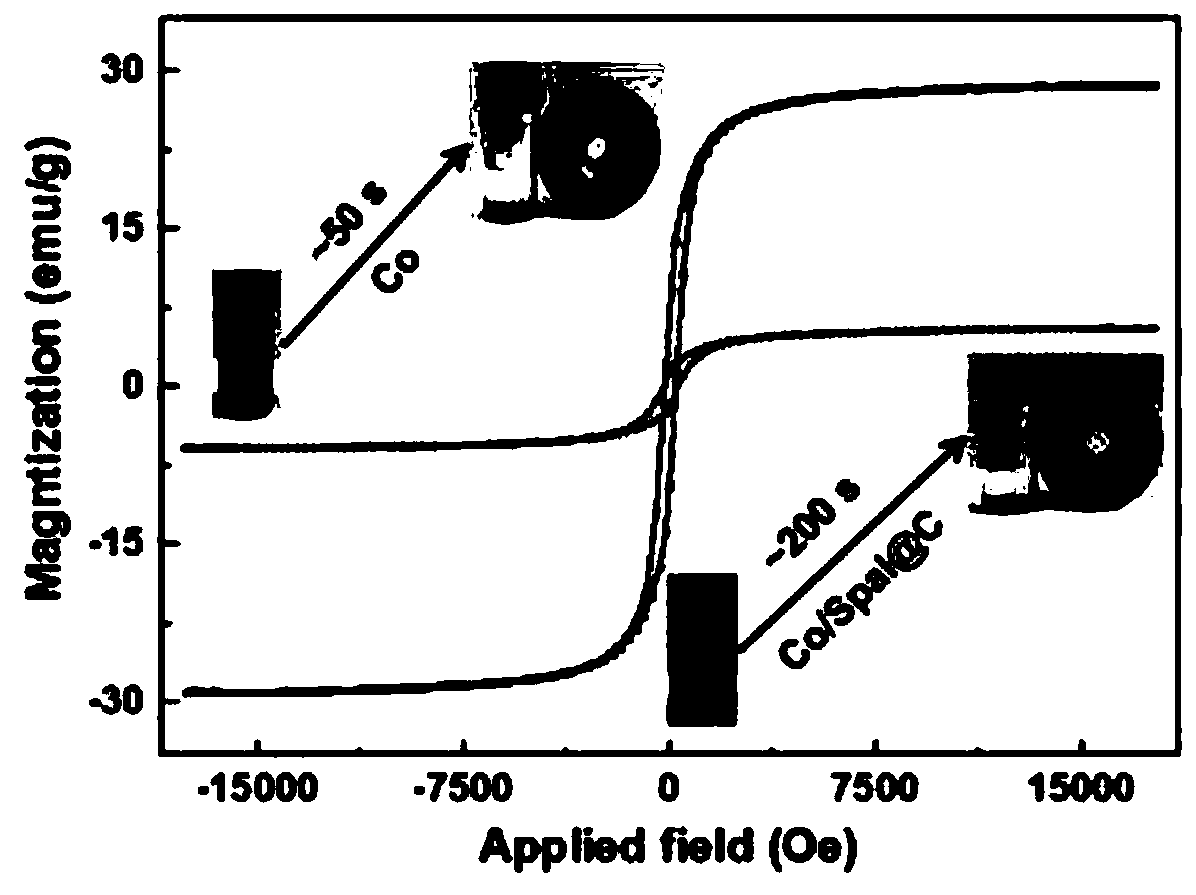

[0035] (1) Preparation of cobalt carbon attapulgite composite materials.

[0036] Step a: Modification of raw ore attapulgite: 1) Purification: first, sieve the raw ore attapulgite with a 150-mesh sieve to obtain attapulgite raw ore powder (Pal powder) for later use; weigh 5.0g of the sieved Pal powder+ 2.0g NH 4 Cl+1.0g NaCl in a 500mL beaker, then add 232.0mL deionized water+11.0mL concentrated HNO 3 +7.0mL concentrated H 2 SO 4 Stir vigorously for 4 hours; after stirring, immerse for 0.5 hours, pour out the upper liquid, and only filter the lower part, wash with absolute ethanol and deionized water until neutral, and finally dry at 80°C; 2) Surface activation and production Hole: acidify the above dried sample with 250.0mL of HCl solution with a concentration of 5mol / L for 2 hours, filter with suction after acidification, wash with absolute ethanol and deionized water until neutral, and finally place in an oven Dry at 80°C.

[0037] Step b: Preparation of glucose-modif...

Embodiment 2

[0049] (1) Preparation of cobalt carbon attapulgite composite materials.

[0050] Step a: Same as Example 1.

[0051] Step b: Preparation of glucose-modified attapulgite precursor: namely, the surface of modified attapulgite adsorbs carbon source, weigh 3.0g of modified attapulgite and 0.75g of glucose into a 500mL beaker, add 40.0mL of deionized water and continue Stir for 24 hours, and then place in a water bath at 80° C. until the water evaporates to prepare a precursor.

[0052] Step c: Put the precursor in a tube furnace with a helium gas flow rate of 40mL / min, a heating rate of 10°C / min, and roast at 700°C for 4h to obtain Pal@C.

[0053] Step d: Weigh 5.0g of the carbon-coated attapulgite composite into a polytetrafluoroethylene cup, then add 5.0mL of 40wt% HF, then add 45.0mL of water, react and etch for 6 hours at room temperature, and then carry out suction filtration. The product obtained after suction filtration was stirred and reacted with 60.0 mL concentrated H...

Embodiment 3

[0059] (1) Preparation of cobalt carbon attapulgite composite materials.

[0060] Step a: Same as Example 1.

[0061] Step b: Preparation of glucose-modified attapulgite precursor: namely, the surface of modified attapulgite adsorbs carbon source, weigh 3.0g modified attapulgite and 3.0g glucose into a 500mL beaker, add 40.0mL deionized water and continue Stir for 24 hours, and then place in a water bath at 80° C. until the water evaporates to prepare a precursor.

[0062] Step c: Put the precursor in a tube furnace with a nitrogen gas flow rate of 40mL / min, a heating rate of 8°C / min, and roast at 900°C for 2.5h to obtain Pal@C.

[0063] Step d: Weigh 5.0g of carbon-coated attapulgite composite into a polytetrafluoroethylene cup, then add 5.0mL of 40wt% HF, then add 45.0mL of water, react and etch at room temperature for 10h, and then carry out suction filtration. The product obtained after suction filtration was stirred and reacted with 6.0 mL concentrated HCl at 30°C for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com