Centimeter sized graphdiyne synthesized through liquid-liquid interface polymerization reaction and application

A technology of graphyne and solution, which is applied in the field of centimeter-scale graphyne and its preparation, can solve the problems of difficulty in uniform thickness and shape of graphyne film, limit the application of graphyne products, and uncontrollable synthesis, etc., achieving good application prospects, The effect of good continuous uniformity and excellent electronic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

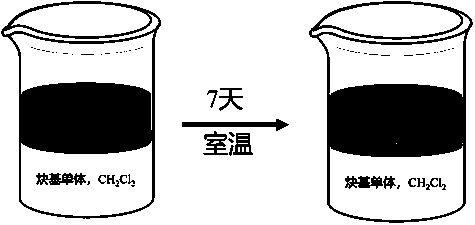

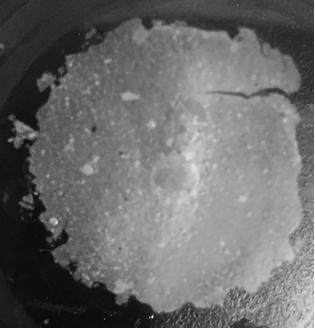

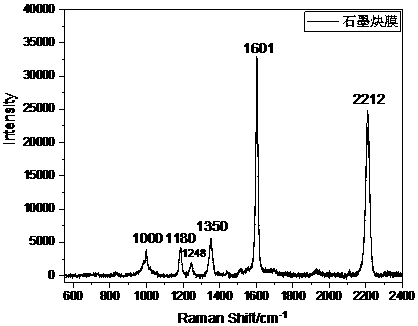

[0037] Example 1 Preparation of graphyne membrane using tetrakis(4-ethynylphenyl)methane as alkyne monomer

[0038] 1. Preparation of tetrakis(4-ethynylphenyl)methane

[0039] (1) At room temperature, add tetraphenylmethane and bromine into the flask and stir for 5 hours, then transfer the obtained product to -78°C, and slowly add ethanol solution until no precipitation occurs; The precipitated product was washed and separated with a saturated sodium thiosulfate solution, and the separated product was purified through a column to obtain product A (510 mg, 29%) as a white solid.

[0040] (2) 0.8 g of white solid product A, 108 mg of PdCl 2 and 24.6 mg of CuI were dissolved in 30 mL of i-Pr 2NH and 0.86 mL of trimethylsilylacetylene solution, and reacted for 42 h under nitrogen protection, the obtained product was purified by column to obtain off-white solid product B (0.6 g, 67%).

[0041] (3) At room temperature, 0.6 g of product B, 0.33 g of NaOH, 10 mL of methanol and 40 ...

Embodiment 2

[0057] Example 2 Preparation of graphyne membrane using tetrakis(4-ethynylphenyl)methane as alkyne monomer

[0058] A reaction similar to that in Example 1 was carried out, except that the concentration of the tetrakis(4-ethynylphenyl)methane solution in Example 1 was changed to 1 mM, and the tetrakis(4-ethynylphenyl)methane, copper acetate The concentration ratio of the substance and pyridine is 10:20:1. Through this reaction, graphyne membranes with lateral dimensions on the order of centimeters were obtained. Compared with the graphyne film obtained under the conditions of Example 1, the graphyne film obtained under this condition is thinner and more fragile, and relatively speaking, the graphyne film structure of Example 1 is more stable.

Embodiment 3

[0059] Example 3 Preparation of graphyne membrane using tetrakis(4-ethynylphenyl)methane as alkyne-based monomer

[0060] A reaction similar to that in Example 1 was carried out, except that the concentration of the tetrakis(4-ethynylphenyl)methane solution in Example 1 was changed to 4 mM, and the tetrakis(4-ethynylphenyl)methane, copper acetate The concentration ratio of the substance and pyridine is 40:20:1. Through this reaction, graphyne membranes with lateral dimensions on the order of centimeters were obtained. Compared with the graphyne film obtained under the conditions of Example 1, the graphyne film obtained under this condition is thicker, but the cost is higher, and the economic applicability is not as good as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com