Heat discoloration varnish and preparation method thereof

A temperature-sensitive color-changing and varnish technology, which is applied in the field of temperature-sensitive color-changing varnish and its preparation, can solve the problems of not being suitable for occasions with high weather resistance requirements, and the color-changing lag of temperature-sensitive color-changing coatings, so as to improve storage stability and adhesion , high color retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

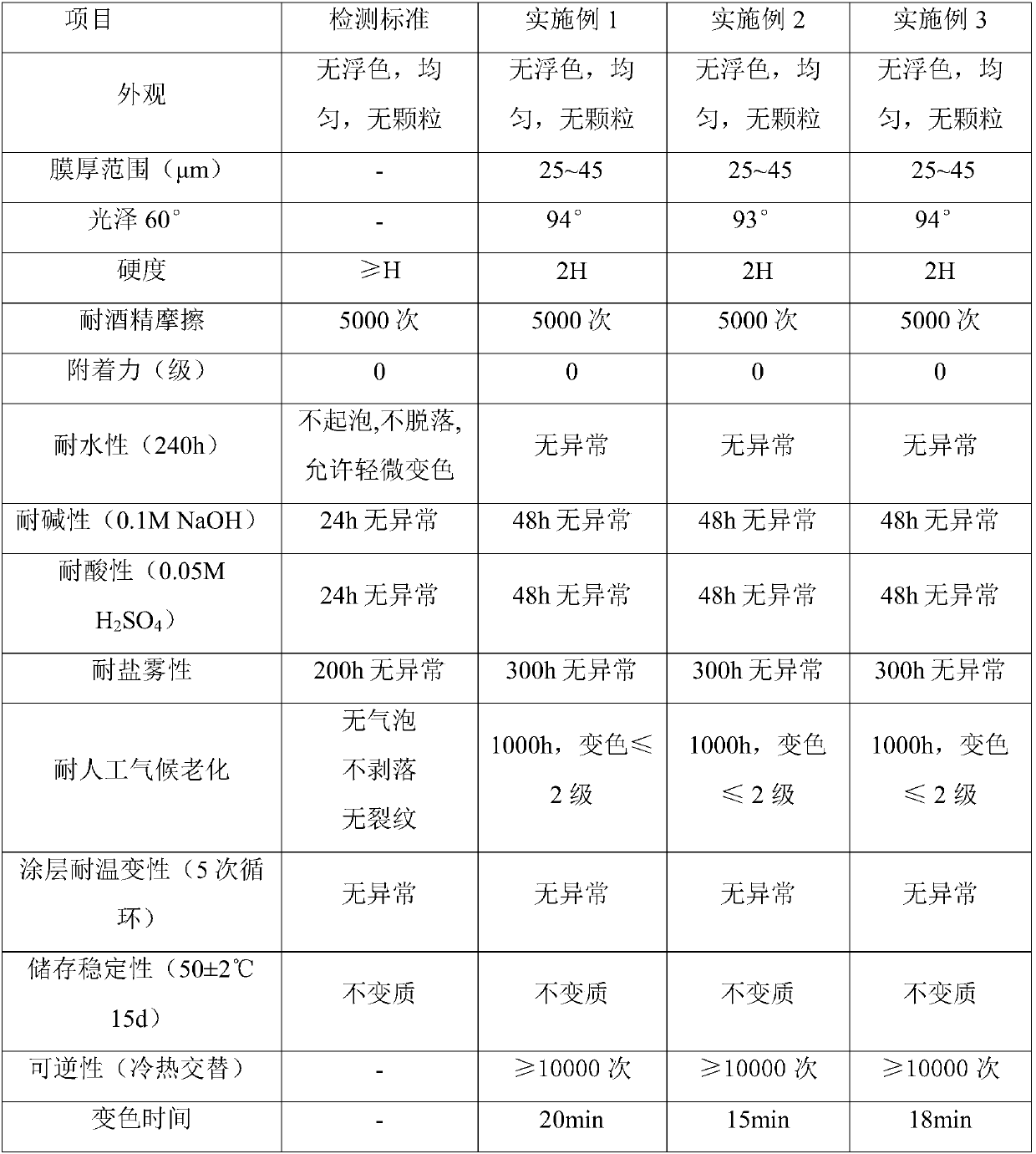

Embodiment 1

[0036] The embodiment of the present invention provides a temperature-sensitive color-changing varnish, including 35 parts of color paste, 45 parts of emulsion, 10 parts of water and 35 parts of curing agent;

[0037]Wherein, the color paste includes the following raw material components in parts by weight: 35 parts of hydroxyl polyacrylic acid aqueous dispersion, 65 parts of reversible thermochromic pigment, 0.5 part of defoamer and 8 parts of deionized water;

[0038] The emulsion includes the following raw material components in parts by weight: 25 parts of hydroxyl polyacrylic acid aqueous dispersion, 38 parts of hydroxyl polyacrylate resin, 0.8 parts of dimethylethanolamine, 8 parts of ethylene glycol butyl ether, and 3 parts of dipropylene glycol methyl ether , 5 parts of UV stabilizer, 4 parts of UV absorber, 2 parts of leveling agent and 3 parts of deionized water;

[0039] The curing agent includes the following raw material components in parts by weight: 65 parts of ...

Embodiment 2

[0047] The embodiment of the present invention provides a temperature-sensitive color-changing varnish, including 40 parts of color paste, 55 parts of emulsion, 5 parts of water and 30 parts of curing agent;

[0048] Wherein, the color paste includes the following raw material components in parts by weight: 25 parts of hydroxyl polyacrylic acid aqueous dispersion, 70 parts of reversible thermochromic pigment, 0.8 parts of defoamer and 5 parts of deionized water;

[0049] The emulsion includes the following raw material components in parts by weight: 30 parts of hydroxypolyacrylic acid aqueous dispersion, 35 parts of hydroxypolyacrylate resin, 0.5 part of dimethylethanolamine, 6 parts of ethylene glycol butyl ether, and 5 parts of dipropylene glycol methyl ether , 4 parts of UV stabilizer, 5 parts of UV absorber, 3 parts of leveling agent and 4 parts of deionized water;

[0050] The curing agent includes the following raw material components in parts by weight: 70 parts of isoc...

Embodiment 3

[0058] The embodiment of the present invention provides a temperature-sensitive color-changing varnish, including 45 parts of color paste, 50 parts of emulsion, 15 parts of water and 28 parts of curing agent;

[0059] Wherein, the color paste includes the following raw material components in parts by weight: 15 parts of hydroxyl polyacrylic acid aqueous dispersion, 68 parts of reversible thermochromic pigment, 1 part of defoamer and 10 parts of deionized water;

[0060] The emulsion includes the following raw material components in parts by weight: 38 parts of hydroxyl polyacrylic acid aqueous dispersion, 25 parts of hydroxyl polyacrylate resin, 1 part of dimethylethanolamine, 10 parts of ethylene glycol butyl ether, and 7 parts of dipropylene glycol methyl ether , 3 parts of UV stabilizer, 3 parts of UV absorber, 4 parts of leveling agent and 5 parts of deionized water;

[0061] The curing agent includes the following raw material components in parts by weight: 75 parts of is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com