Method for promoting rapid formation of hypha ball

A technology of mycelium balls and rotating speed, which is applied in the field of environmental microorganisms, can solve the problems of difficult to obtain quickly, affect the application of mycelium balls, and low ball formation rate, so as to shorten the time of ball formation, compact external structure, and high ball formation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041](1) Prepare the bacterial suspension of Talaromyces flavus S1: take Talaromyces flavus S1 preserved on the slant medium, inoculate it in sterilized water with glass beads, place it on a shaker at 28±2°C for shaking culture, and perform hemocytosis Counting, the obtained concentration is 6.7×10 7 Individual / L of spore suspension of Talaromyces flavus S1.

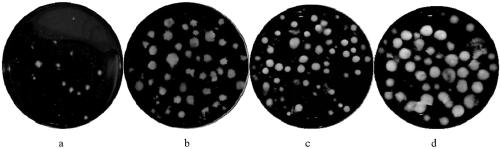

[0042] (2) Cultivate Talaromyces flavus S1 mycelial balls: Take an appropriate amount of spore suspension and inoculate them into 12 PDB medium at a volume ratio of 10%, and divide them into four groups, namely blank group, control group 1, and control group 2 and test group 1. There are three shake flasks in each group as three parallels. The four groups were cultured in four shakers respectively. The rotation speed of the blank group was 0, the rotation speed of the control group 1 was 150 rpm, the rotation speed of the control group 2 was 200 rpm, and the rotation speed of the test group 1 was set at 200 rpm, and ...

Embodiment 2

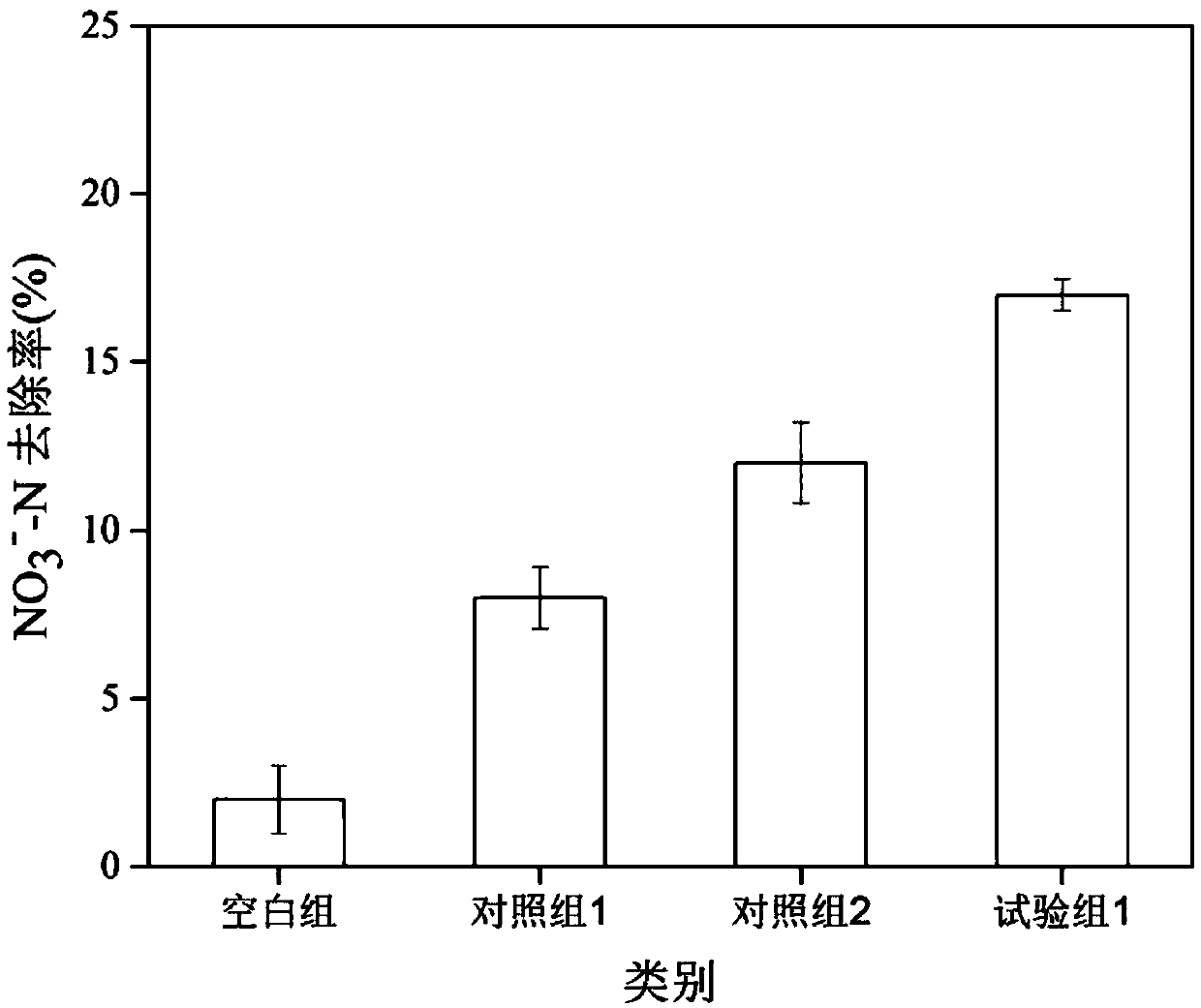

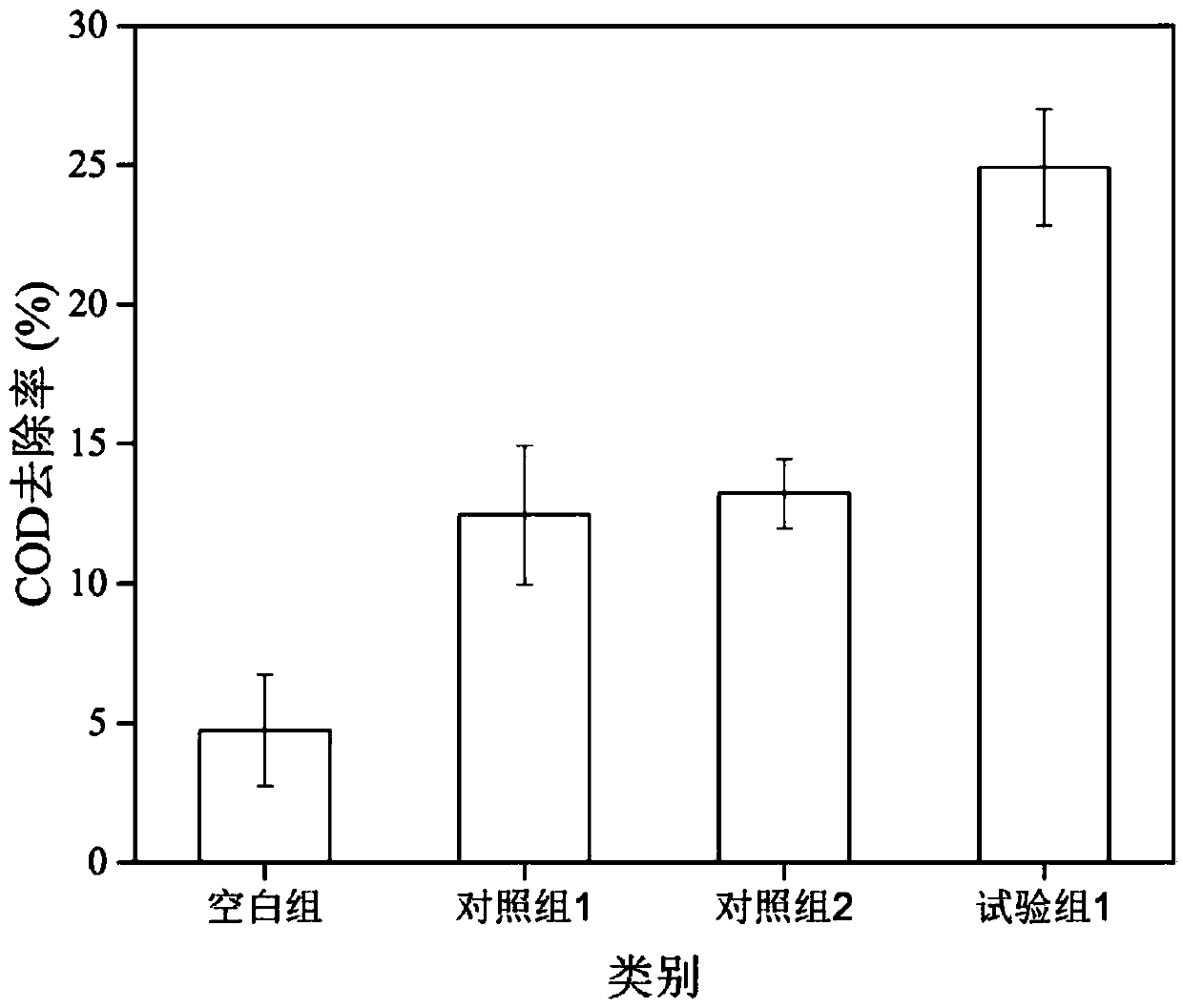

[0050] (1) Get the mycelia balls prepared by each group in 10ml of Example 1, and add it to NO by a volume ratio of 10% 3 — In 100ml nitrate wastewater (Table 2) of N135.48mg / L, COD 1036.5mg / L, pH 7.9, observe the adsorption capacity of mycelium balls to nitrate wastewater. Measure COD and NO every 6 hours 3 - -N removal rate, the result is as figure 2 , as shown in 3.

[0051] Table 2

[0052]

[0053] figure 2 For the mycelium ball prepared in Example 1 to NO 3 - -N removal case. Mycelial balls with a rotational speed of 0 (blank group), the NO 3 - -N removal rate was 2.04%. When the rotating speed was 150rpm (control group 1), the mycelium NO 3 - -N removal rate was 8.15%. When the rotating speed was 200rpm (control group 2), the mycelium NO 3 - -N removal rate was 12.04%. However, during the cultivation process, the rotating speed of the shaking table was adjusted to 200rpm-150rpm-200rpm (test group 1) successively, and the hyphae balls had no effect ...

Embodiment 3

[0059] (1) Take 10 mL of mycelium balls prepared by each group in Example 1, add 10% volume ratio to 100 mL of ammonia nitrogen wastewater (Table 3), and observe the adsorption capacity of mycelium balls to nitrate wastewater. Measure COD and NH every 6 hours 4 + -N removal rate ( Figure 5 , 6).

[0060] table 3

[0061]

[0062] Such as Figure 5 As shown, when the rotating speed is 0 (blank group), the removal rate of ammonia nitrogen in the ammonia nitrogen wastewater by the mycelium ball formed by it is only 4.26%, which is negligible. When the rotating speed was 150rpm (control group 1), the ammonia nitrogen removal efficiency of the mycelial balls formed reached 12.47%; when the rotating speed was 200rpm (control group 2), the ammonia nitrogen removal rate of the mycelial balls formed was 17.58%. , Stronger adsorption capacity than mycelial balls formed at 150rpm. However, when the rotational speed was changed during the cultivation process, the mycelial balls ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com