Composite gas sensing material, preparation method thereof, gas sensor and applications thereof

A gas sensor and gas sensitive material technology, which is applied in material resistance, material analysis, material analysis by electromagnetic means, etc., can solve problems such as heating, and achieve the effects of increasing accessibility, increasing adsorption sites, and improving sparsity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The composite gas-sensing material in this embodiment includes reduced graphene oxide, and the surface of reduced graphene oxide is loaded with zero-dimensional cuprous oxide quantum dots; reduced graphene oxide is multilayer reduced graphene oxide, and two adjacent layers of reduced graphene oxide A support material is filled between them, and the support material is three-dimensional cuprous oxide nanoparticles.

[0043] The composite gas-sensitive material in this specific embodiment adopts the mechanical mixing method to make, and electron microscope figure is as follows figure 1 Shown: Francium cone-shaped cuprous oxide nanoparticles are distributed in piles, and the reduced graphene oxide is also unevenly distributed.

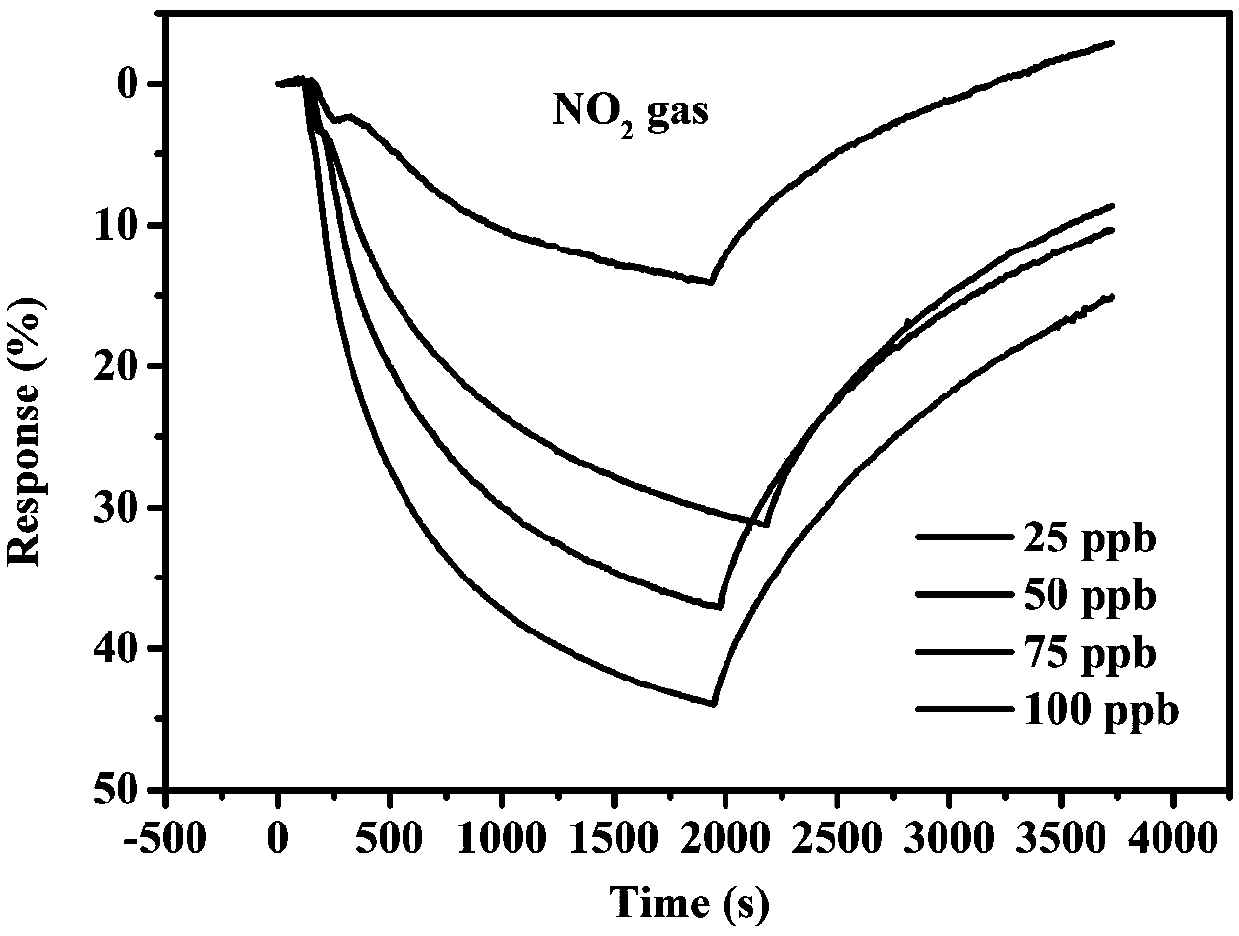

[0044] The gas response of the gas sensor made of the gas sensitive composite material prepared in this example at normal temperature is as follows: figure 2 Shown: The figure shows the response of the gas sensor to different concentrations of ni...

Embodiment 2

[0046]The composite gas-sensing material in this embodiment includes reduced graphene oxide, and the surface of reduced graphene oxide is loaded with zero-dimensional cuprous oxide quantum dots; reduced graphene oxide is multilayer reduced graphene oxide, and two adjacent layers of reduced graphene oxide A support material is filled between them, and the support material is a one-dimensional cuprous oxide nanowire.

[0047] The composite gas-sensitive material in this specific embodiment adopts the mechanical mixing method to make, and electron microscope figure is as follows image 3 Shown: the reduced graphene oxide and one-dimensional cuprous oxide nanowires are evenly distributed, but there is no obvious hole structure, and the nanowire structure tends to aggregate into bundles.

Embodiment 3

[0049] The composite gas-sensitive material in this embodiment includes reduced graphene oxide, and the surface of the reduced graphene oxide is loaded with zero-dimensional cuprous oxide quantum dots; the reduced graphene oxide is a multilayer reduced graphene oxide, and two adjacent layers of reduced graphite oxide A support material is filled between the olefins, and the support material includes a one-dimensional cuprous oxide nanowire and a three-dimensional cuprous oxide nanoparticle.

[0050] The composite gas-sensing material of this embodiment is prepared by chemical synthesis, using copper acetate solution, graphene oxide dispersion, sodium hydroxide solution and vitamin C solution with a volume ratio of 4:2.5:5:6, and includes the following steps :

[0051] Step 1: Take copper acetate and add it to ultrapure water to form a copper acetate solution with a concentration of 2 mg / ml, and add the copper acetate solution to a graphene oxide dispersion with a concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com