NiO-ZnO ball-chain-shaped nano-material and preparation method and application thereof

A nanomaterial, ni-zn technology, applied in the field of nanomaterials, can solve the problems of ball chain nanostructure materials that have not been reported, and achieve good photocatalytic effect, simple process and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] In a second aspect, in at least one embodiment, a method for preparing the above-mentioned NiO-ZnO ball chain nanomaterial is provided, comprising the following steps:

[0068] Mix the alcoholic solution of the nickel source, the alcoholic solution of the zinc source, and the alcoholic solution of the alkali metal hydroxide and then mix it with the reducing agent, then place the mixed solution in a parallel magnetic field, and carry out solid-liquid reaction after the heating reaction. Separation, the separated solid product is washed, dried and oxidized to obtain the nanometer material.

[0069] The above-mentioned "parallel magnetic field" refers to a magnetic field in which the lines of force are parallel straight lines, which can be realized by the following method: put two square magnets opposite each other, and the N pole of one magnet is facing the S pole of the other magnet.

[0070] The process of the above method is simple and efficient, and the nanometer mate...

Embodiment 1

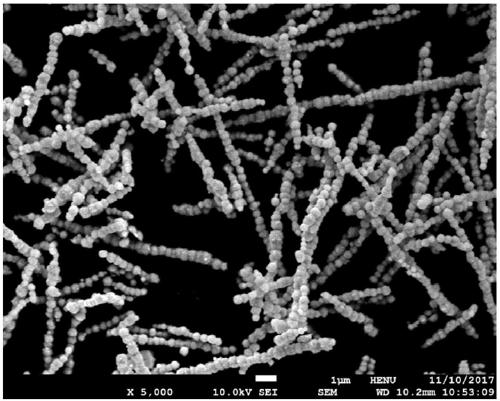

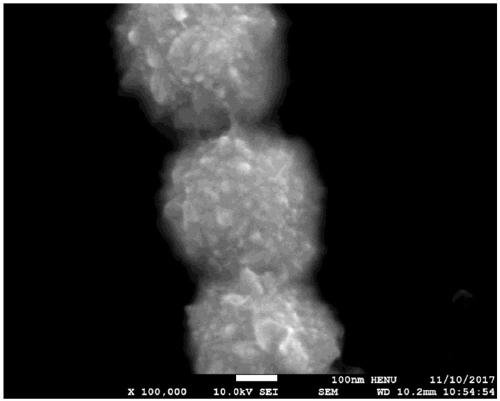

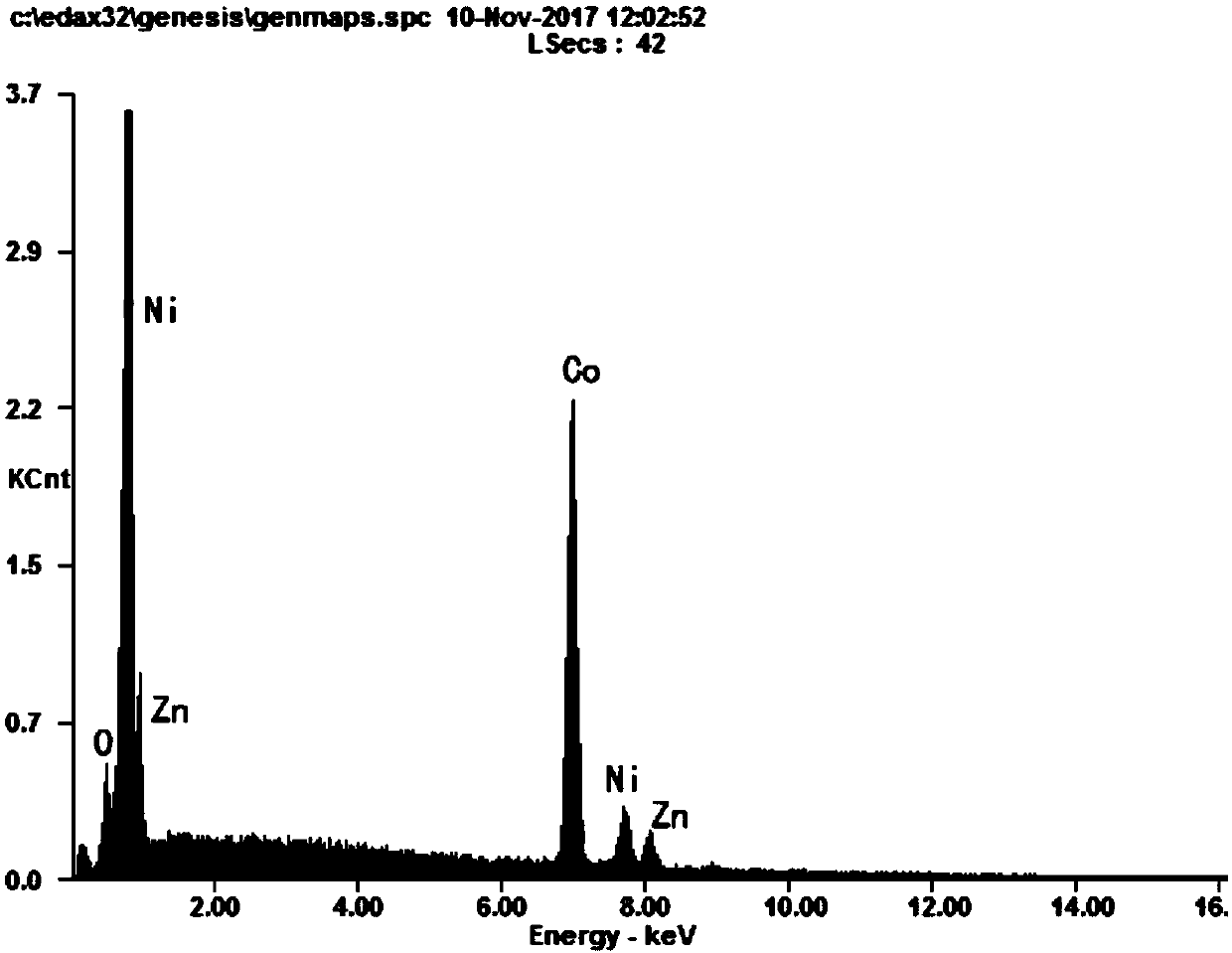

[0107] A NiO-ZnO spherical chain nanomaterial, the nanomaterial is mainly formed by sequentially connecting NiO-ZnO spherical particles; the NiO-ZnO spherical particles are made of Ni-Zn as the core and NiO-ZnO as the shell Particles with a core-shell structure.

[0108] The above-mentioned nanomaterials are prepared by the following methods:

[0109] (a) Weigh 0.119g nickel chloride hexahydrate (NiCl 2 ·6H 2 O) and 0.0292g zinc chloride (ZnCl 2 ) was dissolved in 5mL of ethylene glycol (EG) to obtain a solution ①;

[0110] Wherein, the concentration of nickel source is 0.1mol / L, and the concentration of zinc source is 0.0428mol / L;

[0111] (b) Weigh 1.2g of sodium hydroxide (NaOH) and dissolve it in 25mL of ethylene glycol (EG) to obtain a solution ②;

[0112] Wherein, the concentration of sodium hydroxide is 1.2mol / L;

[0113] (c) Ultrasonic treatment of solution ① and solution ② respectively, and stirring for 30 minutes until completely dissolved;

[0114] (d) After ...

Embodiment 2

[0123] A NiO-ZnO ball chain nanomaterial, different from Example 1, in step (a) of the preparation method of the nanomaterial in this example: the concentration of the nickel source is 0.15mol / L, and the concentration of the zinc source is 0.02mol / L, the nickel source is nickel sulfate, and the zinc source is zinc sulfate. All the other are identical with embodiment 1.

[0124] It is found by SEM observation that the nanomaterial is in the shape of a ball chain, with a diameter of about 500 nm and a length of about 30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com