Application of lignin and derived carbon thereof in anaerobic digestion

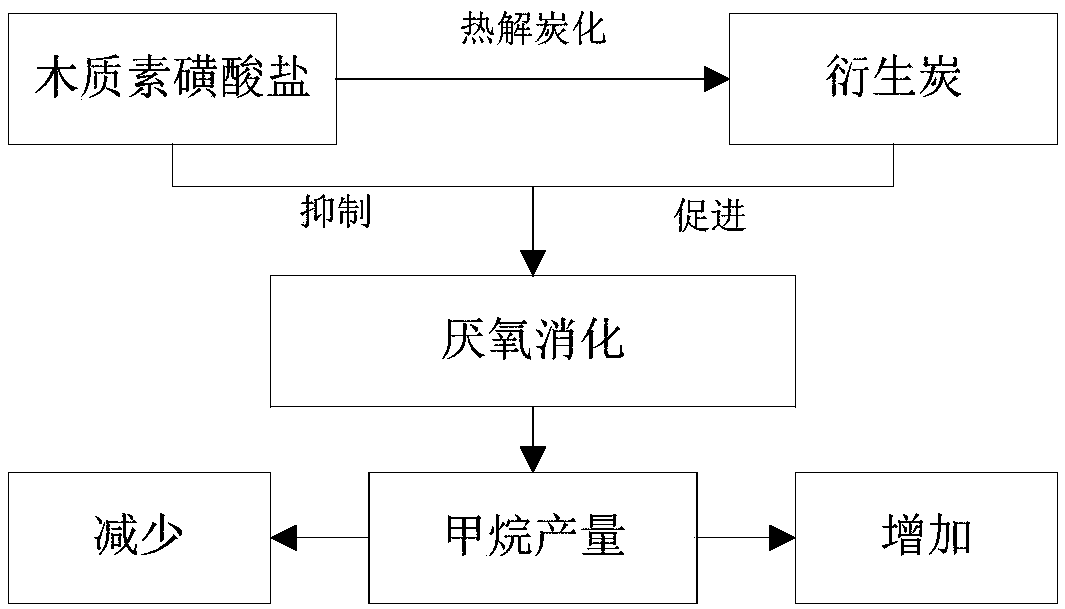

A technology of anaerobic digestion and derivation of carbon, which is applied in anaerobic digestion treatment, carbon preparation/purification, chemical instruments and methods, etc., which can solve the problems of microbial toxicity inhibition, high value-added lignosulfonate utilization efficiency, Poor biodegradability and other problems, to achieve the effect of increasing methane production and realizing high-value utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

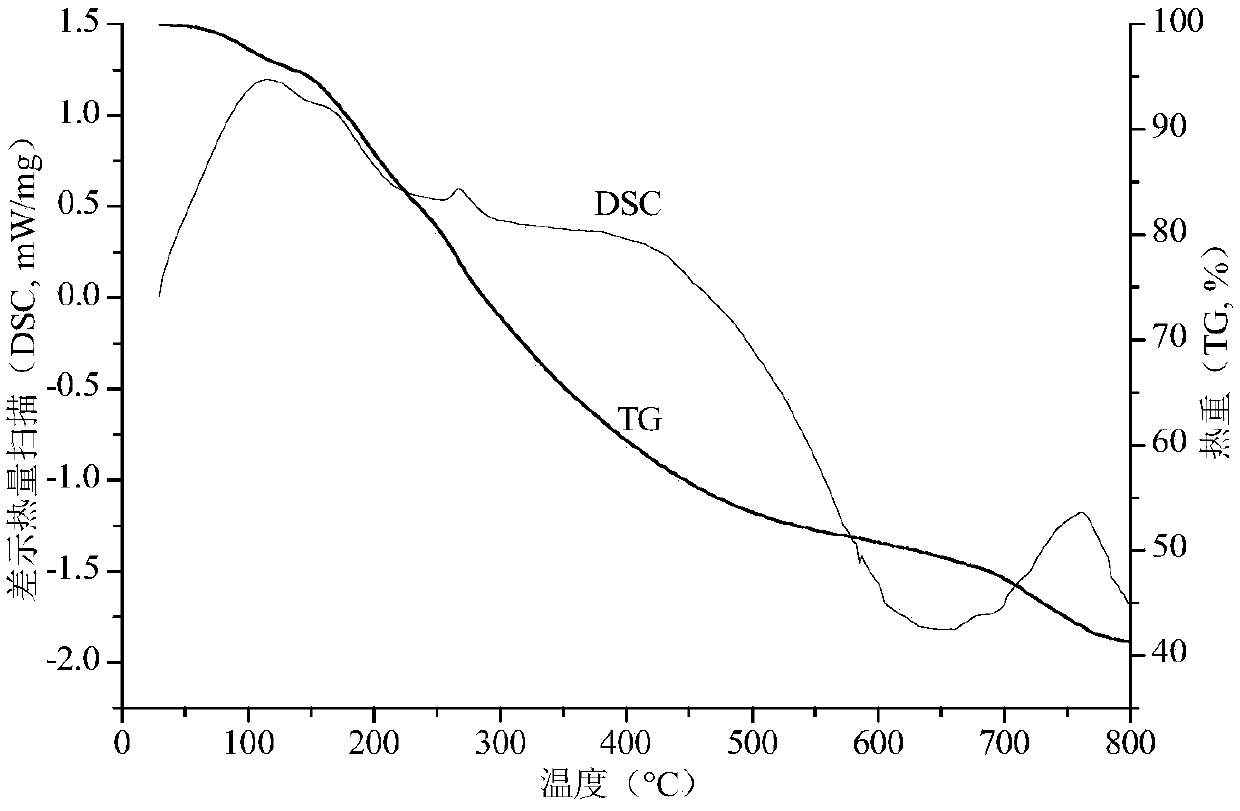

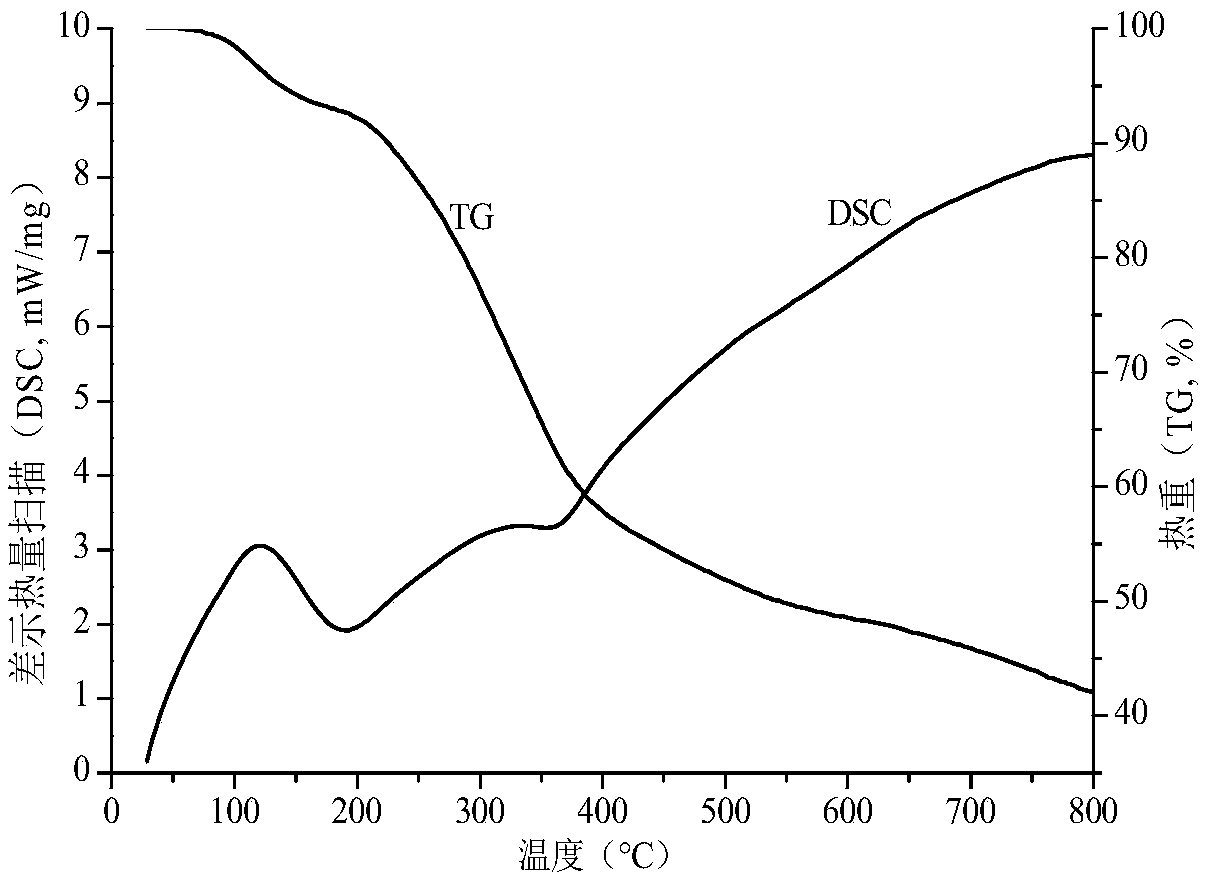

[0055] (1) Preparation of lignosulfonate-based derivatized charcoal: Derived charcoal was prepared by temperature programming method. Sodium lignosulfonate (calcium) was dried at 85° C. for 24 hours, and then pulverized into a powder with a particle size of 100 mesh by a high-speed pulverizer. Weigh 40g of dried sodium lignosulfonate (calcium) powder, place it in a ceramic crucible, cover the surface with pebbles of different sizes, compact and seal it, put it into a temperature-programmed furnace, pass nitrogen gas into it for 20 minutes, and discharge it from the furnace Air, then heat up to 100°C at a rate of 10°C / min for preheating, heat evenly and then heat up to 400°C, constant temperature pyrolysis for 2 hours, cool to room temperature and crush into powder with a particle size of 100 mesh, put it in a brown glass bottle for later use .

[0056] (2) Cultivation of inoculated sludge: The remaining sludge was taken from the sludge dewatering room of Jinan West Wastewater...

Embodiment 2

[0064] (1) Preparation of lignosulfonate-based derivatized charcoal: Derived charcoal was prepared by temperature programming method. Sodium lignosulfonate (calcium) was dried at 90° C. for 36 h, and then pulverized into a powder with a particle size of 100 mesh by a high-speed pulverizer. Weigh 40g of dried sodium lignosulfonate (calcium) powder, place it in a ceramic crucible, cover the surface with pebbles of different sizes, compact and seal it, put it into a temperature-programmed furnace, pass nitrogen gas into it for 20 minutes, and discharge it from the furnace Air, then heat up to 100°C at a rate of 10°C / min for preheating, heat evenly and then heat up to 400°C, thermolyze for 2 hours at a constant temperature, cool down to room temperature, crush into powder with a particle size of 100 mesh, and pack it in a brown glass bottle for later use .

[0065] (2) Cultivation of inoculated sludge: The remaining sludge was obtained from Jinan West Wastewater Treatment Plant, ...

Embodiment 3

[0068] (1) Preparation of lignosulfonate-based derivatized charcoal: Derived charcoal was prepared by temperature programming method. Sodium lignosulfonate (calcium) was dried at 100° C. for 18 hours, and then pulverized into a powder with a particle size of 100 mesh by a high-speed pulverizer. Weigh 40g of dried sodium lignosulfonate (calcium) powder, place it in a ceramic crucible, cover the surface with pebbles of different sizes, compact and seal it, put it into a temperature-programmed furnace, pass nitrogen gas into it for 20 minutes, and discharge it from the furnace Air, then heat up to 100°C at a rate of 5°C / min for preheating, heat evenly and then heat up to 200°C, thermolyze for 1 hour at a constant temperature, cool to room temperature and crush into powder with a particle size of 100 mesh, put it in a brown glass bottle for later use .

[0069] (2) Cultivation of inoculated sludge: The remaining sludge was obtained from Jinan West Wastewater Treatment Plant, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com