A kind of preparation method of recycled carbon fiber prepreg

A technology for recycling carbon fiber and prepreg, which is applied in the direction of coating, etc., can solve the problems of high-performance application of carbon fiber, easy fiber extraction from the matrix, and low mechanical strength of composite materials, so as to reduce material costs and prevent fiber The effect of orientation damage and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A kind of preparation method of recycled carbon fiber prepreg of the present invention specifically comprises the following steps:

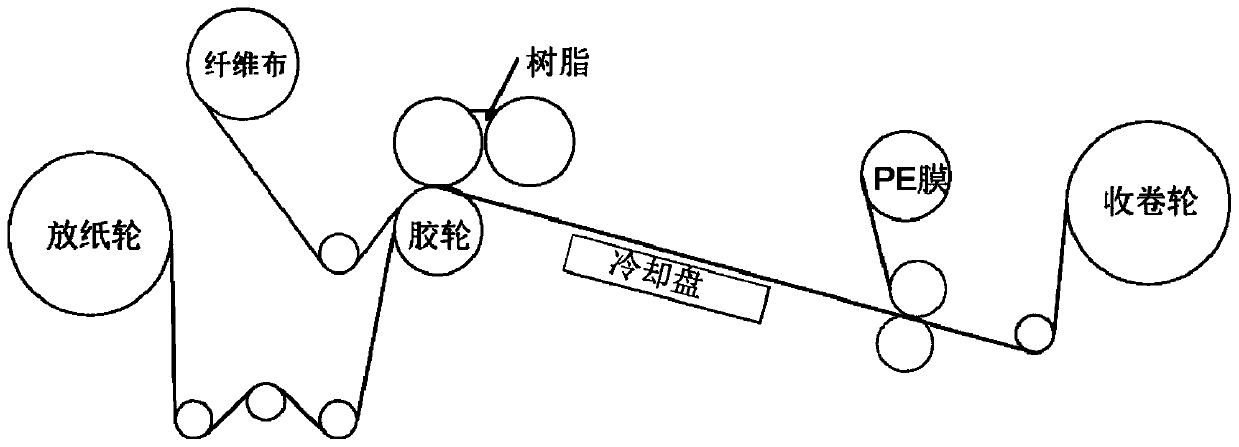

[0018] Heat the thermosetting resin and coat it directly on the recycled carbon fiber cloth, where the coating temperature is 60-100°C, the viscosity of the resin is 2-4Pa·s when coating, and the tension applied to the fiber cloth is 0.1-0.5cN / tex, the fiber cloth feeding speed is 2-3m / min, the resin coating speed is 1.8-2.7m / min, the fluidity of the resin during coating is used to make the resin impregnate the fiber cloth initially, and the resin and fiber cloth are pre-composited and merged. Ensure fiber cloth orientation;

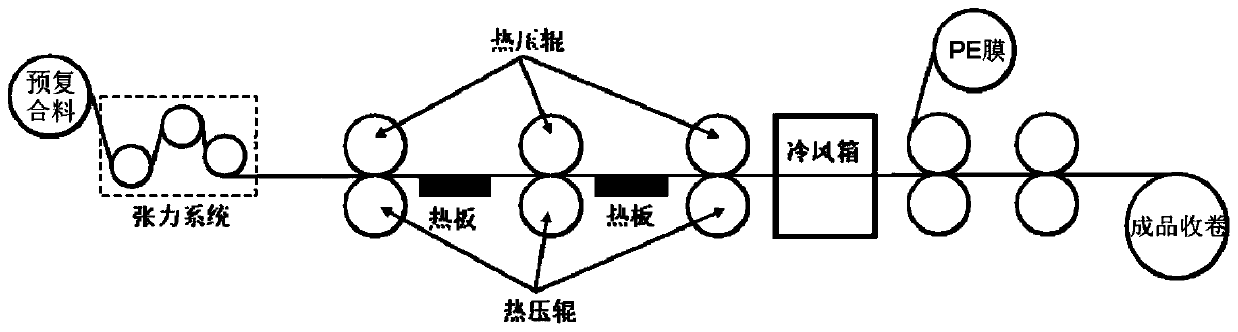

[0019] The pre-composite product of recycled carbon fiber cloth and resin film is further impregnated with an impregnation machine to prepare recycled carbon fiber prepreg; wherein, the tension applied to the fiber-resin pre-composite product is 0.5-2cN / tex, and the impregnation process speed is 5 -6m / min, and use ...

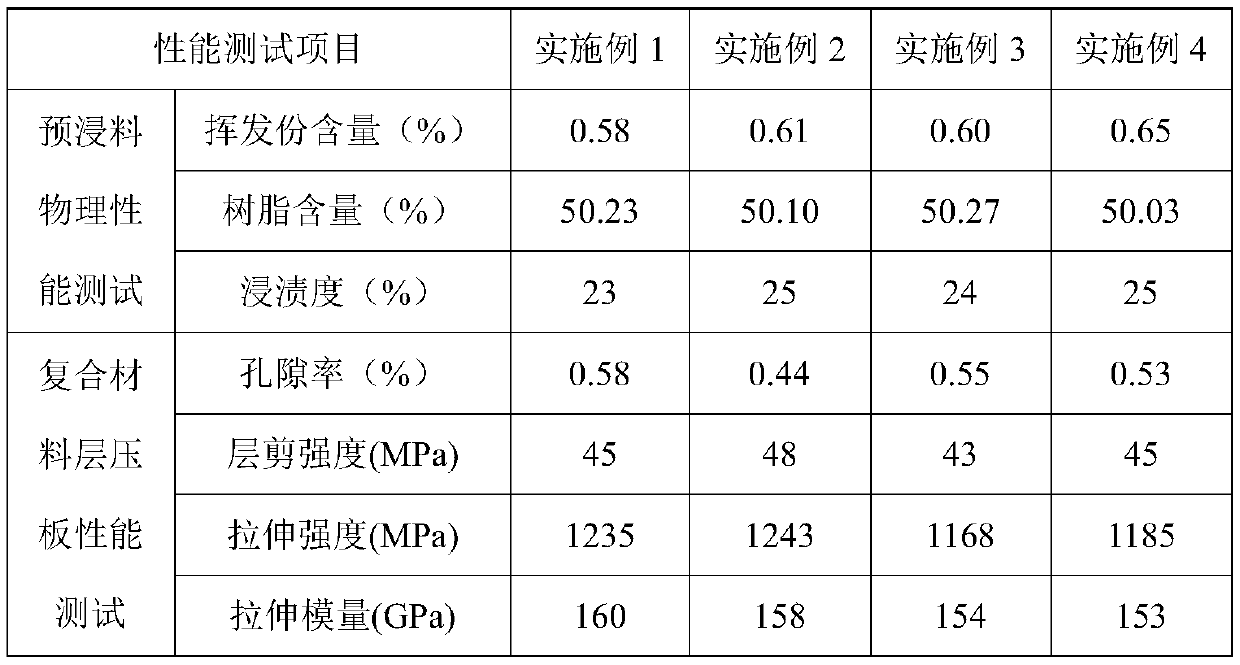

Embodiment 1

[0025] A thermosetting resin component comprising the following parts by mass is used: bisphenol A epoxy resin, 100 parts; diethyltoluenediamine, 40 parts. A recycled carbon fiber oriented cloth with an area density of 10gsm (area density variance of 0.2), a fiber orientation of 80%, and a weight ratio of recycled carbon fiber to dispersant of 97:3, wherein the fiber length is 6mm, and the dispersant is methyl cellulose , the degree of cross-linking is 10%.

[0026] Prepare recycled carbon fiber prepregs as follows:

[0027] Heat the thermosetting resin with a hot-melt coater and coat it directly on the recycled carbon fiber cloth, where the coating temperature is 60 °C, the viscosity of the resin is 2 Pa s during coating, and the tension applied to the fiber cloth is 0.1 cN / tex, the feeding speed of the fiber cloth is 2m / min, and the resin coating speed is 1.8m / min, so that the resin is preliminarily impregnated with the fiber cloth, so as to realize the pre-composite of th...

Embodiment 2

[0031] A thermosetting resin component comprising the following parts by mass is used: thermosetting phenolic resin, 100; hexamethylenetetramine, 30. A recycled carbon fiber oriented cloth with an area density of 80gsm (area density variance of 0.5), a fiber orientation degree of 85%, and a weight ratio of recycled carbon fiber to dispersant of 97:3, wherein the fiber length is 4mm, and the dispersant is dopamine, cross-linked The degree is 30%.

[0032] Prepare recycled carbon fiber prepregs as follows:

[0033] Heat the thermosetting resin with a hot-melt coater and coat it directly on the recycled carbon fiber cloth, where the coating temperature is 80 °C, the viscosity of the resin is 2.5 Pa s during coating, and the tension applied to the fiber cloth is 0.2 cN / tex, the feeding speed of the fiber cloth is 2.5m / min, and the resin coating speed is 2.3m / min, so that the resin is preliminarily impregnated with the fiber cloth, so as to realize the pre-composite of the resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com