Solar energy heat-conducting medium and preparation method thereof

A heat-conducting medium and solar energy technology, applied in the petrochemical field, can solve the problems of fast consumption rate of inorganic salt type corrosion inhibitor, short service life, serious environmental pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

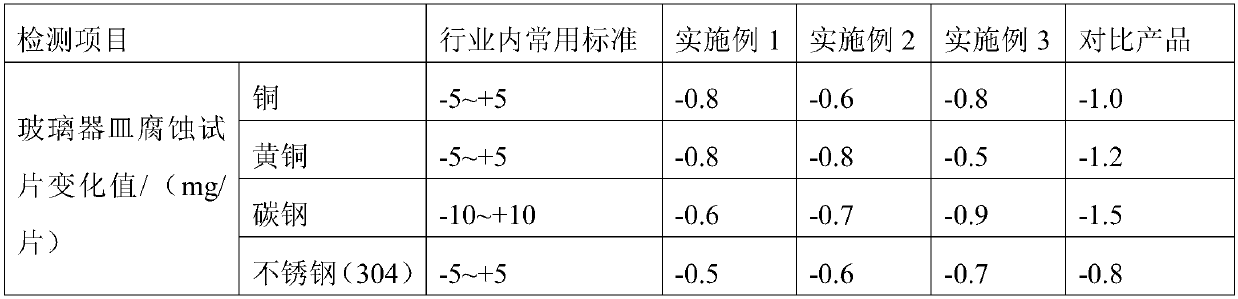

Examples

Embodiment 1

[0024] A solar heat conduction medium, based on the total mass of the heat conduction medium raw materials as 100%, wherein the components and their mass fractions are as follows: 30% ethylene glycol, 2% isooctanoic acid, 3% succinic acid, citric acid 1%, benzotriazole 1%, sulfamethoxypyridazine 5%, organosiloxane (Yantai Hengxin Chemical Technology Co., Ltd. THIF-298) 0.1%, fluorescent green (Hunan Jinqiao Chemical Co., Ltd.) 0.001%, Sodium hydroxide 0.5%, the balance is water.

[0025] A preparation method of the solar heat conduction medium described in this embodiment, the method is a composite method, first, add water and ethylene glycol in a stirred tank, mix well and then add isooctanoic acid, succinic acid, benzotriazole and sodium hydroxide, and stir evenly; after the corrosion inhibitor is completely dissolved, add sulfamethoxypyridazine, organosiloxane and fluorescent green and stir to dissolve to obtain a mixed solution, which is filtered to obtain a solar heat con...

Embodiment 2

[0027] A solar heat conduction medium, based on the total mass of the heat conduction medium raw materials as 100%, wherein the components and their mass fractions are as follows: 44% ethylene glycol, 2% octanoic acid, 1.5% sodium benzoate, 1% succinic acid %, benzotriazole 0.5%, sulfamethoxypyridazine 10%, organosiloxane (Yantai Hengxin Chemical Technology Co., Ltd. THIF-298) 0.5%, fluorescent green (Hunan Jinqiao Chemical Co., Ltd.) 0.001%, hydrogen Sodium oxide 1%, the balance is water.

[0028] A preparation method of the solar heat conduction medium described in this embodiment, the method is a composite method, first, add water and ethylene glycol in a stirred tank, mix well and then add octanoic acid, sodium benzoate, succinic acid, benzotri Nitrazole and sodium hydroxide, and stir evenly; After the corrosion inhibitor is completely dissolved, add sulfamethoxypyridazine, organosiloxane and fluorescent green and stir to dissolve, obtain a kind of solar heat conduction me...

Embodiment 3

[0030] A solar heat conduction medium, based on the overall mass of the heat conduction medium raw materials as 100%, wherein the components and their mass fractions are as follows: 60% propylene glycol, 4% isooctanoic acid, 3% sodium benzoate, and 2% succinic acid , 2-mercaptobenzothiazole 1%, sulfamethoxypyridazine 1%, polyether (Yantai Hengxin Chemical Technology Co., Ltd. THIX-299) 1%, sodium hydroxide 0.1%, and the balance is water.

[0031] A preparation method of the solar heat conduction medium described in this embodiment, the method is a composite method, first, add water and propylene glycol in a stirred tank, mix well and then add isooctanoic acid, sodium benzoate, succinic acid, 2-mercaptobenzene and thiazole and sodium hydroxide, and stir evenly; after the corrosion inhibitor is completely dissolved, add sulfamethoxypyridazine and polyether to stir and dissolve, filter to obtain a solar heat conduction medium of the present invention, and pack to form a product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com