Oil special for ethanol gasoline engine and preparation method thereof

A technology of ethanol gasoline and engine, which is applied in the field of lubricating oil. It can solve the problems of strong corrosion, carbon deposit and coking in the engine, and achieve the effects of excellent acid neutralization ability, reduced carbon deposit and good oil film retention ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

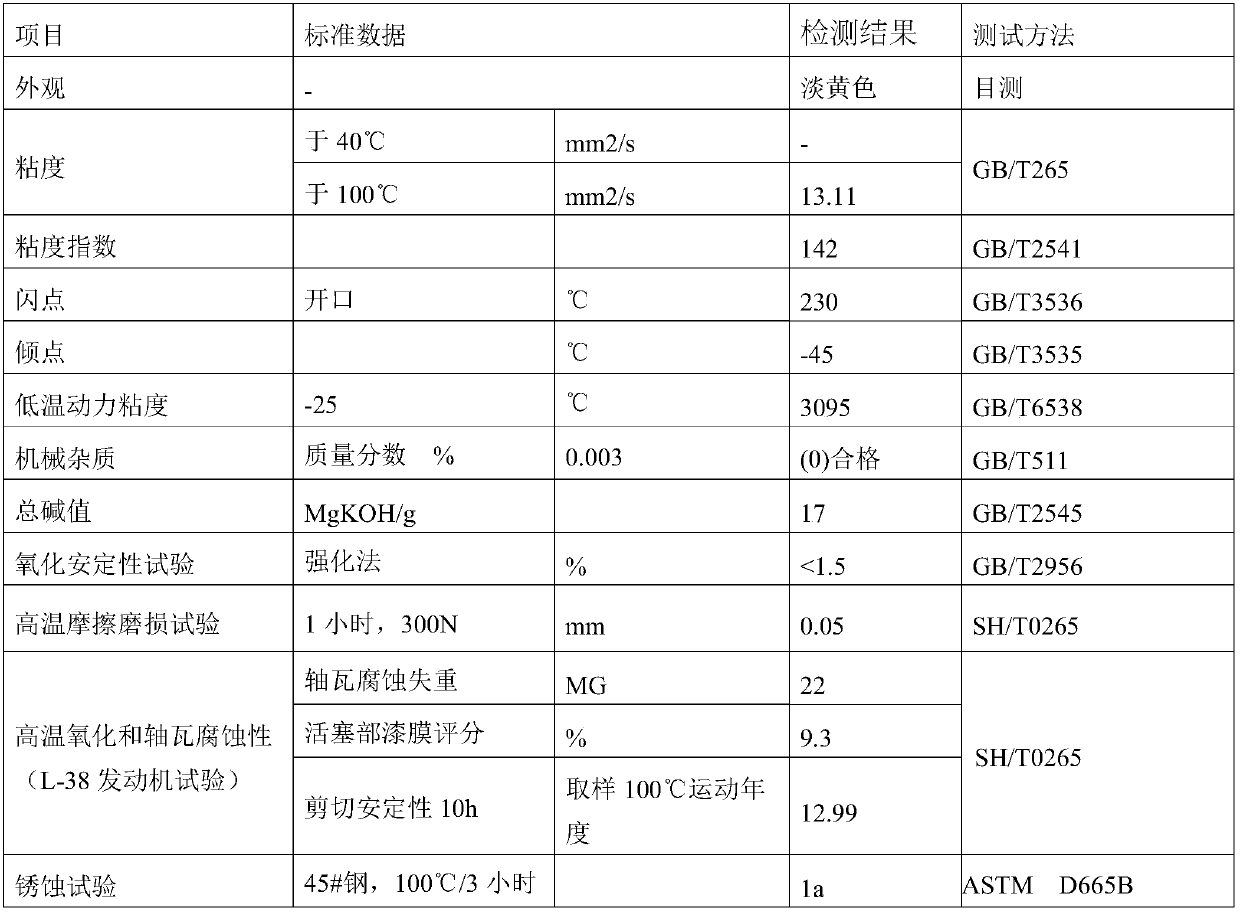

Image

Examples

Embodiment 1

[0024] A preparation method of special oil for ethanol gasoline engine, comprising the steps of:

[0025] (1) Weigh 100N 727kg of Class III hydrorefined base oil, 150kg of polyalphaolefin synthetic base oil PAO150 and 60kg of pentaerythritol ester into a blending kettle with stirring function, heat to 55°C and stir evenly;

[0026] (2) Keep stirring, weigh 15kg of α-naphthylamine, 20kg of ethyl borate, 10kg of barium stearate, 10kg of calcium alkyl salicylate, 5kg of benzotriazole, 3kg of polymethyl methacrylate and formaldehyde Slowly add 0.2kg of base silicone oil into the blending kettle, raise the temperature to 65°C, continue stirring at constant temperature for 0.5h, and obtain the ethanol gasoline engine special oil after sampling and testing pass.

Embodiment 2

[0028] A preparation method of special oil for ethanol gasoline engine, comprising the steps of:

[0029] (1) Weigh 804kg of Class III hydrotreated base oil 100N, polyalphaolefin synthetic base oil PAO150 100kg, and pentaerythritol ester 100kg into a blending kettle with stirring function, heat to 56°C and stir evenly;

[0030] (2) Keep stirring, weigh 15kg of diphenylamine sulfide, 30kg of ethyl borate, 10kg of zinc stearate, 10kg of calcium alkyl salicylate, 2kg of benzotriazole, 4kg of polymethyl methacrylate and methyl Slowly add 0.3kg of silicone oil into the blending kettle, raise the temperature to 66°C, continue to stir at a constant temperature for 0.5h, and obtain the special ethanol gasoline engine oil after sampling and testing pass.

Embodiment 3

[0032] A preparation method of special oil for ethanol gasoline engine, comprising the steps of:

[0033] (1) Weigh 550kg of Class III hydrotreated base oil 100N, 250kg of polyalphaolefin synthetic base oil PAO150 and 50kg of trimethylolpropane ester into a blending kettle with stirring function, heat to 52°C and stir evenly ;

[0034] (2) Keep stirring, weigh N,N'-di-sec-butyl-p-phenylenediamine 30kg, triisopropyl borate 40kg, barium stearate 18kg, alkyl magnesium salicylate 10kg, dialkyl disulfide Add 0.9kg of zinc phosphate, 5kg of polymethyl methacrylate and 0.5kg of methyl silicone oil into the blending kettle slowly, raise the temperature to 67°C, continue stirring at constant temperature for 0.8h, and obtain the ethanol gasoline engine special oil after sampling and testing pass .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com