Silicon PU (polyurethane) elastic floor structure and manufacture method thereof

An elastic and ground technology, applied in the direction of pavement, construction, road, etc., can solve the problems of poor self-adhesion and mutual adhesion of rubber particles, insufficient toughness and tensile strength, insufficient resilience of rubber particles, etc., and achieve good yellowing resistance. , moderate hardness and elasticity, good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A kind of silicon PU elastic ground structure, its manufacture method comprises the following steps:

[0066] 1) Pretreatment of the base layer: cleaning, dust removal, washing and drying of the cement concrete base layer;

[0067] 2) Waterproof primer: apply the waterproof paint on the cement concrete base layer and dry to form a waterproof primer;

[0068] 3) Silicon PU elastic layer: first, silicon-modified polyurethane resin, talcum powder, calcium carbonate, titanium nickel yellow, polycarboxylate sodium salt, non-ionic polysiloxane defoamer, ultraviolet absorber UV-531 and ring Oxysiloxane is mixed evenly, then TPEE particles are added and mixed evenly, and then the obtained mixture is laid on the waterproof primer layer and dried to form a silicon PU elastic layer (thickness is 5mm);

[0069] 4) Wear-resistant surface layer: apply a two-component modified acrylic topcoat on the silicon PU elastic layer, and dry to form a wear-resistant surface layer to obtain a ...

Embodiment 2

[0074] A kind of silicon PU elastic ground structure, its manufacture method comprises the following steps:

[0075] 1) Pretreatment of the base layer: cleaning, dust removal, washing and drying of the asphalt concrete base layer;

[0076] 2) Waterproof primer: apply the waterproof paint on the asphalt concrete base layer and dry to form a waterproof primer;

[0077] 3) Silicon PU elastic layer: first, silicon-modified polyurethane resin, barium sulfate, diatomaceous earth, titanium nickel yellow, polycarboxylate sodium salt, metal soap defoamer, ultraviolet absorber UV-326 and epoxy silicon The oxane is mixed evenly, and then TPEE particles are added to mix evenly, and then the obtained mixture is laid on the waterproof primer layer and dried to form a silicon PU elastic layer (thickness is 9mm);

[0078] 4) Wear-resistant surface layer: apply a two-component modified acrylic topcoat on the silicon PU elastic layer, and dry to form a wear-resistant surface layer to obtain a ...

Embodiment 3

[0083] A kind of silicon PU elastic ground structure, its manufacture method comprises the following steps:

[0084] 1) Pretreatment of the base layer: cleaning, dust removal, washing and drying of the cement concrete base layer;

[0085] 2) Waterproof primer: apply the waterproof paint on the cement concrete base layer and dry to form a waterproof primer;

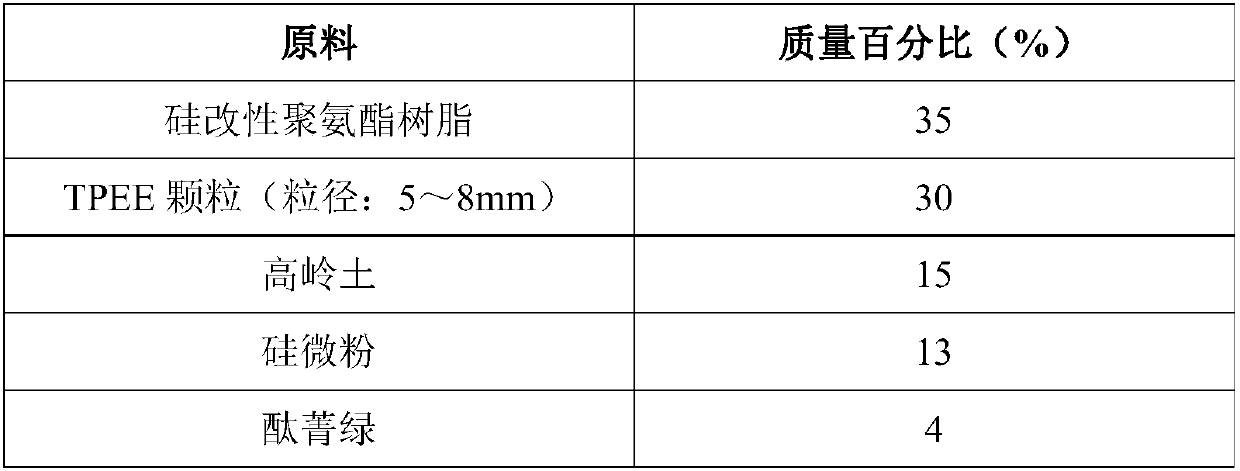

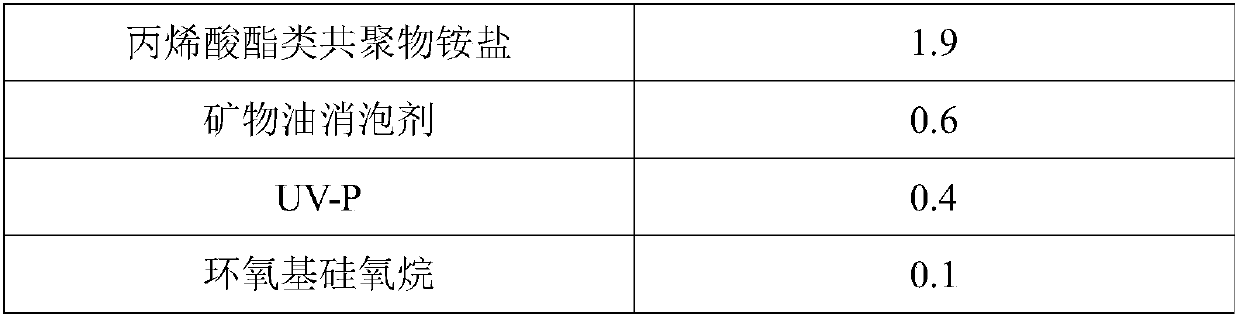

[0086] 3) Silicon PU elastic layer: firstly silicon-modified polyurethane resin, talcum powder, cobalt blue, polymer alkyl alcohol ammonium salt, non-ionic polysiloxane defoamer, ultraviolet absorber UV-P and epoxy The siloxane is mixed evenly, then TPEE particles are added and mixed evenly, and then the obtained mixture is laid on the waterproof primer layer and dried to form a silicon PU elastic layer (thickness is 5mm);

[0087] 4) Wear-resistant surface layer: apply a two-component modified acrylic topcoat on the silicon PU elastic layer, and dry to form a wear-resistant surface layer to obtain a silicon PU elastic gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com