Hybrid dynamic polymer composition

A technology of polymer and composition, applied in the field of hybrid dynamic polymer composition, can solve the problem that the characteristics of dynamic reversible covalent bond are difficult to fully reflect, and achieve the effect of excellent self-healing property and unique low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

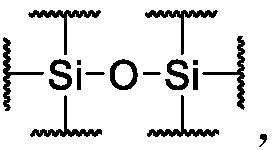

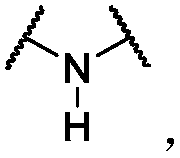

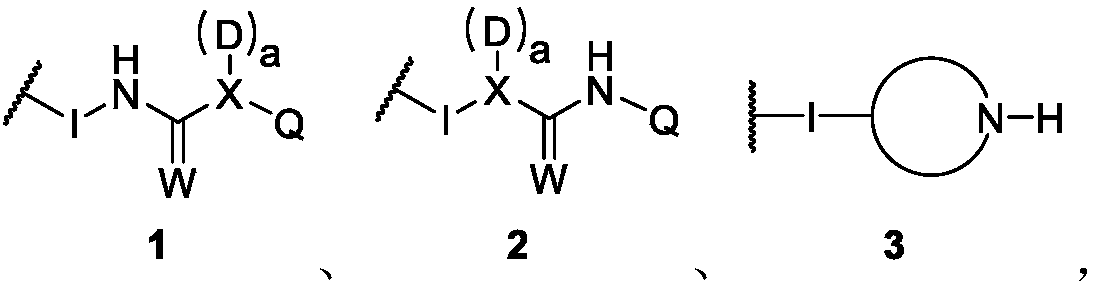

Method used

Image

Examples

preparation example Construction

[0180] In the preparation process of dynamic polymers, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam dynamic polymers.

[0181] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the dynamic polymer to make it a uniform foam, and then through physical Or chemical changes make it shape and become a foam material. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0182] Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the dynamic polymer, which includes but not limited to the following methods: (1) inert gas foaming method, that is, after adding Press the inert gas into the molten polymer or pasty material under pressure, and then ...

Embodiment 1

[0236] 1,5-Divinylhexamethyldisiloxane and 3-buten-1-ol are mixed at a molar ratio of 1:1, and reacted in toluene under the action of the initiator benzamide peroxide to obtain Compound 1 whose side group contains a hydroxyl group; compound 1 and methyl isocyanate are mixed in a molar ratio of 1:0.5, and reacted in dichloromethane to obtain a compound 2 whose side group contains a carbamate group. Dissolve compound 2 in DMSO, add 0.05 molar equivalent of cellulose nanocrystals, stir and mix for 6 hours, and keep the solvent to prepare a dynamic polymer solution, which can be coated on the surface of the material, Forms a tough film after drying.

Embodiment 2

[0238]

[0239] Dichloromethylvinylsilane is hydrolyzed and condensed in dilute hydrochloric acid, and the product is neutralized to near neutrality with sodium carbonate to obtain a polysiloxane with a side group having a double bond and an average molecular weight of about 7000; take 50g of polysiloxane Siloxane is reacted with 0.3g of 6-aminothiouracil in dichloromethane through thiol-ene click reaction, and then the amino group and hydroxyl group in the product are reacted with a sufficient amount of isopropyl isocyanate, and the solvent is removed. A polysiloxane with side groups containing hydrogen bonding groups; add 0.1g of conductive graphite, 0.2mg of BHT antioxidant, and 0.5g of sodium hydroxide to the above-mentioned product, stir and mix to obtain gray-black polysiloxane rubbery material. It was made into a dumbbell-shaped sample with a size of 80.0×10.0×2.0mm, and a tensile test was carried out using a tensile testing machine. The tensile rate was 10mm / min. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com