Method for preparing wave absorbing materials from biomass carbon sources

A technology of biomass carbon sources and absorbing materials, applied in carbon preparation/purification, chemical instruments and methods, and other chemical processes, can solve problems such as long synthesis time, complex synthesis methods, and pollution, and achieve improved technology Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

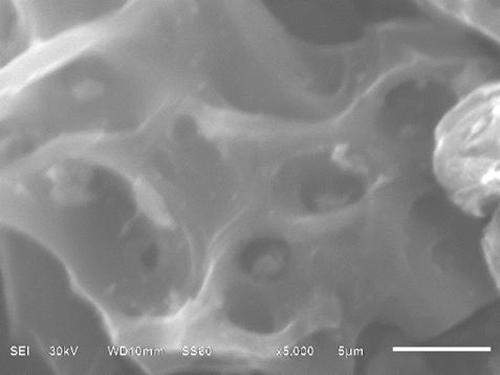

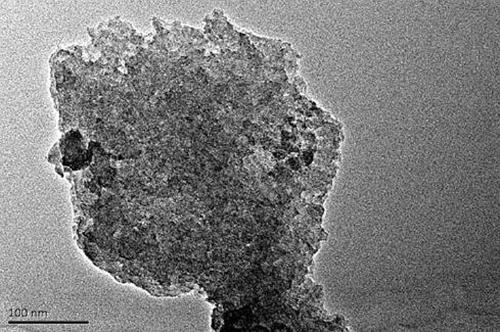

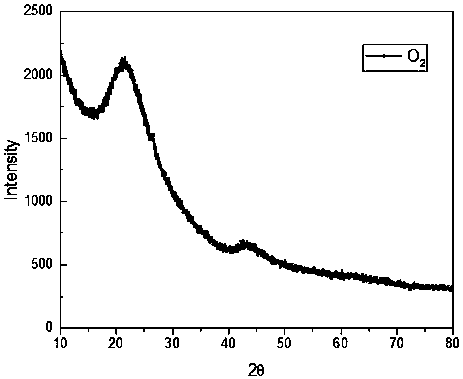

Image

Examples

Embodiment 1

[0029] A method for preparing a wave absorbing material by utilizing a biomass carbon source, the synthesis steps are as follows:

[0030] 1. Perform ultrasonic treatment on the biomass carbon source with water, acetone and alcohol in turn to remove the surface impurities of the biomass carbon source;

[0031] 2. Put the treated biomass carbon source into a vacuum drying box for vacuum drying;

[0032] 3. Put the biomass carbon source after drying in step 2 into a container, place it in a tube furnace, precisely control the temperature and reaction time, and carry out the reaction;

[0033] 4. After the reaction in step 3, the temperature is lowered to room temperature, the container is taken out, the obtained semi-finished product is ground, and then plasma treatment is performed to obtain the finished product.

Embodiment 2

[0035] As an implementation of Example 1, the water in the first step is redistilled water, and the biomass carbon source is rice husk. The container in the step 3 is an alumina porcelain container, and the specific steps are as follows:

[0036] 1. Grind the rice husks with a grinder, obtain micron-sized rice husk powder through multiple grindings, and then place them in secondary water, acetone, and alcohol solutions in turn. minutes, then take out to vacuum dry for 24 hours;

[0037] 2. Take 2 grams of rice husks treated in step 1, put them in an alumina porcelain boat, place them in a tube furnace, then feed nitrogen for 20 minutes, then heat up 10 degrees per minute, slowly heat up to 900°C, and at 900°C After 4 hours of incubation at ℃, the temperature was lowered to terminate the reaction, and the whole process was kept in nitrogen;

[0038] 3. After cooling to room temperature, take out the alumina porcelain boat; pour the product into a mortar and grind for half an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com