High-toughness non-woven coated paper and preparation method thereof

A high-toughness and coating technology, applied in the direction of surface covering paper, textiles and papermaking, paper, etc., can solve the problems of intolerant of folding, brittle decorative paper, etc., and achieve the effect of soft hand, soft paper and environmentally friendly materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

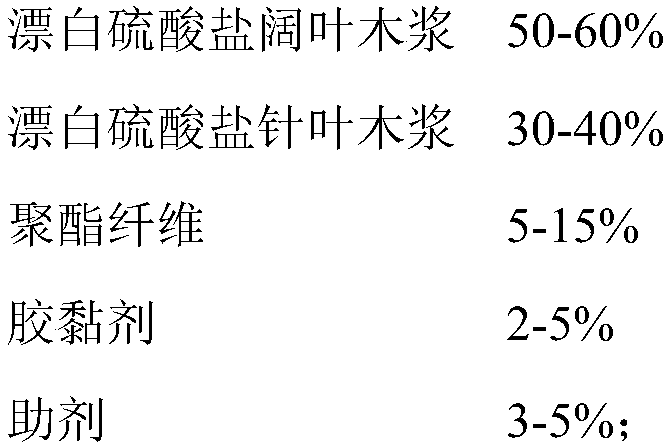

[0049] The high tenacity non-woven covered paper described in this embodiment 1, in terms of mass fraction, has the following composition of raw materials:

[0050]

[0051] Wherein: the polyester fiber is polyethylene terephthalate PET.

[0052] The adhesive is styrene-butadiene latex.

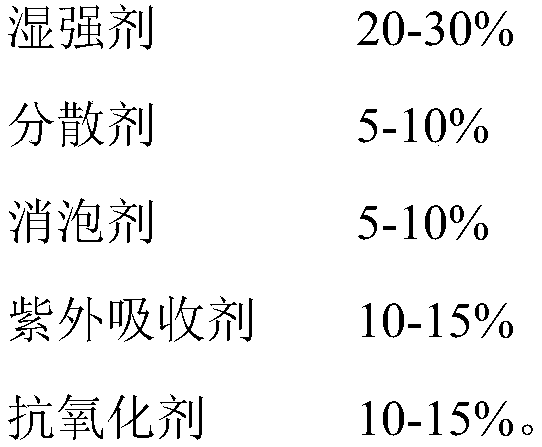

[0053] In terms of mass fraction, the auxiliary composition is as follows:

[0054]

[0055] Wherein: the dispersant is an aqueous solution of polycarboxylate ammonium salt.

[0056] The dry strength agent is cationic acrylamide.

[0057] The wet strength agent is polyamide polyamine epichlorohydrin PAE.

[0058] The antioxidant is butylated hydroxyanisole.

[0059] The defoamer is polydimethylsiloxane.

[0060] The UV absorber is a salicylate type absorber.

[0061] The preparation method of the high tenacity non-woven coated paper described in this embodiment 1 specifically includes the following steps:

[0062] (1) Add bleached kraft hardwood pulp and bleached kraft softwood pul...

Embodiment 2

[0073] The high tenacity non-woven covered paper described in the present embodiment 2, in terms of mass fraction, has the following composition of raw materials:

[0074]

[0075] Wherein: the polyester fiber is polyethylene terephthalate PET.

[0076] The adhesive is a polyurethane resin.

[0077] In terms of mass fraction, the auxiliary composition is as follows:

[0078]

[0079]

[0080] The dispersant is an anionic sodium polyacrylate aqueous solution.

[0081] The dry strength agent is polyacrylamide.

[0082] The wet strength agent is a polyamide polyepichlorohydrin resin.

[0083] The antioxidant is tert-butyl hydroquinone.

[0084] The defoamer is polydimethylsiloxane.

[0085] The UV absorber is a salicylate type absorber.

[0086] The preparation method of the high tenacity non-woven coated paper described in this embodiment 2 specifically includes the following steps:

[0087] (1) adding bleached kraft hardwood pulp and bleached kraft softwood pulp...

Embodiment 3

[0098] The high tenacity non-woven covered paper described in the present embodiment 3, in terms of mass fraction, has the following composition of raw materials:

[0099]

[0100] Wherein: the polyester fiber is polyethylene terephthalate PET.

[0101] Adhesive polyvinyl alcohol.

[0102] In terms of mass fraction, the auxiliary composition is as follows:

[0103]

[0104] The dispersant is an aqueous solution of polycarboxylate ammonium salt.

[0105] The dry strength agent is cationic starch.

[0106] The wet strength agent is polyamide polyamine epichlorohydrin PAE.

[0107] The antioxidant is dibutylhydroxytoluene.

[0108] The defoamer is polydimethylsiloxane.

[0109] The UV absorber is a salicylate type absorber.

[0110] The preparation method of the high tenacity non-woven coated paper described in this embodiment 3 specifically includes the following steps:

[0111] (1) adding bleached kraft hardwood pulp and bleached kraft softwood pulp into a hydrauli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com