A High Precision Fully Differential Capacitance-Voltage Conversion Circuit System

A voltage conversion circuit, fully differential technology, applied in the field of MEMS inertial devices, can solve the problems of increased system power consumption and area, inability to obtain high-precision detection, output signal influence, etc., to suppress zero drift, eliminate low-frequency noise and offset, Improve the effect of changing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

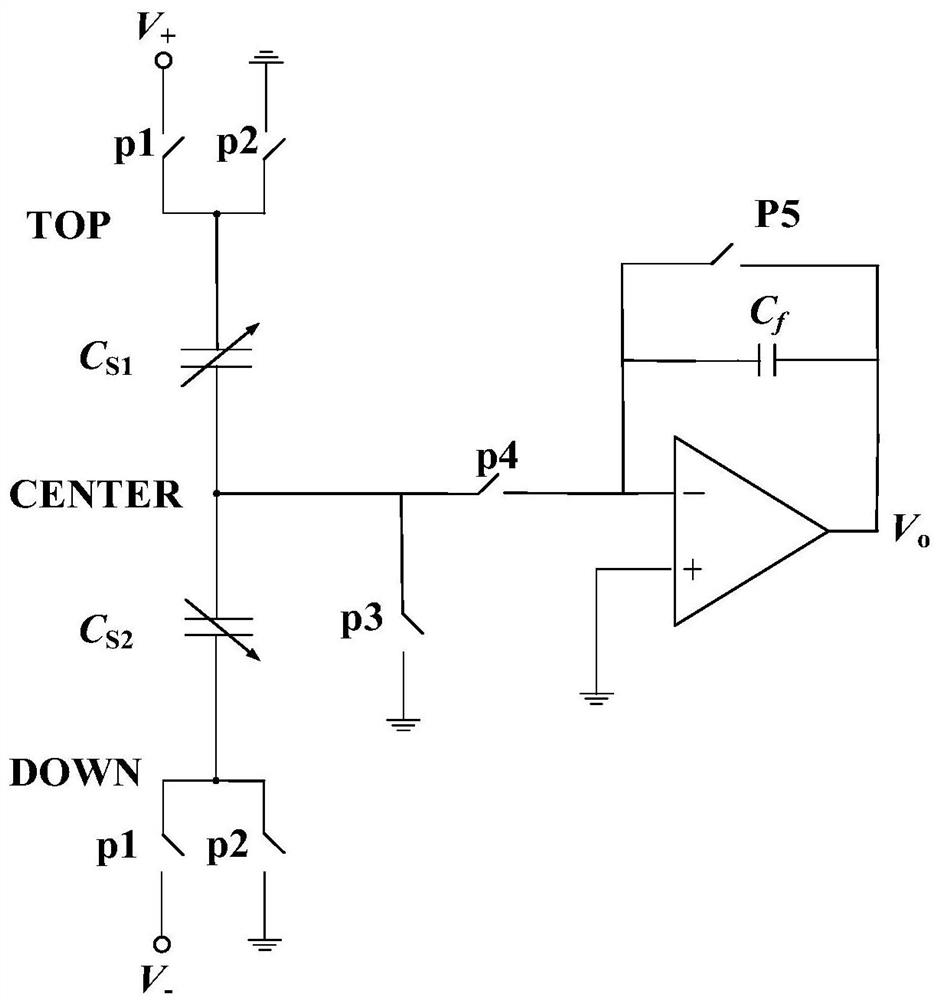

[0026] figure 1 It is a traditional single-ended detection circuit. The overall circuit adopts a single-ended charge amplifier and a switched capacitor structure, which can effectively reduce the influence of parasitic capacitance and improve the accuracy of circuit switching. The working process of the circuit is the charge detection stage and the charge transfer stage. In the charge detection stage: p1 is high level, p2 is low level, p3 is low level, and the sensitive capacitor C S1 and C S2 The upper and lower pole plates are respectively connected to V - and V + , at this time stored in the sensitive capacitor C S1 and C S2 The charges are V + C S1 and V - C S2 . P4 is low level, p5 is high level, the output of the operational amplifier is shorted to the input, the output of the operational amplifier is 0, and the integral capacitor C f Both ends are grounded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com