Waste plastic based hypercrosslinked polymer with adjustable pore size as well as preparation method and application thereof

A super-crosslinking and polymer technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problem of water pollution, difficult to efficiently remove organic pollutant molecules, polystyrene-based Porous materials cannot adapt and meet the needs of production and practical applications, etc., to achieve the effect of solving polluted environment, good market application prospects, and remarkable removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Embodiments of the present invention provide a method for preparing a waste plastic-based hypercrosslinked polymer with adjustable pore size, comprising the following steps:

[0024] Mix the polystyrene foamed plastic with the solvent 1,2-dichloroethane and the crosslinking agent methylal, and after fully dissolving, add the catalyst anhydrous ferric chloride to crosslink for 12 hours at 80°C. The system was cooled to room temperature, washed three times with acetone, dilute hydrochloric acid and water respectively, then extracted with methanol for 24 hours, and dried in vacuum for 12 hours to obtain a hypercrosslinked polymer; polystyrene foamed plastics were selected from waste polystyrene foam Foam plastic; the mass ratio of polystyrene foam plastic to anhydrous ferric chloride is 1:4-1:10, and the mass ratio of polystyrene foam plastic to methylal is 1:10.

[0025] In the above process, if the polystyrene foamed plastic is pre-crosslinked, hypercrosslinked polymers ...

Embodiment 1

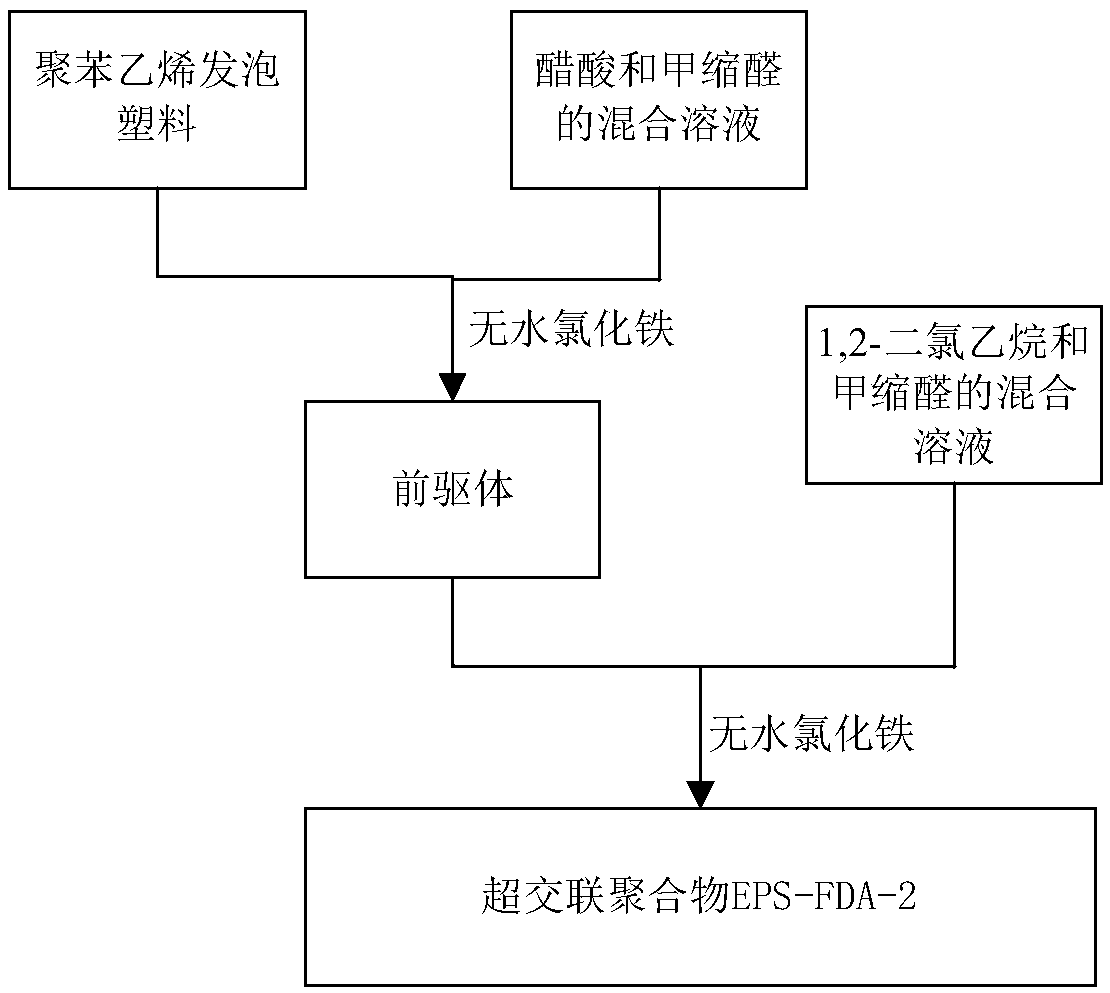

[0030] Embodiment 1: Weigh 0.5006g polystyrene foamed plastic (Expandable Polystyrene; EPS) and dissolve in the mixed solution of 40mL acetic acid and 5.6mL methylal at room temperature, then add 2.23 g anhydrous ferric chloride; The above-mentioned system Carry out pre-crosslinking reaction at 80°C for 1 h, and then carry out purification treatment to obtain the precursor of secondary crosslinking; add 40 mL of 1,2-dichloroethane and 5.6 mL of methylal to the obtained precursor, and then Then add 10g of anhydrous ferric chloride for secondary cross-linking. After the reaction system is cooled to room temperature, wash with acetone, dilute hydrochloric acid and water for 3 times respectively, then extract with methanol for 24 hours, and dry in vacuum for 12 hours to obtain super-cross-linked polymerization. Object EPS-FDA-2.

[0031] The preparation process of the embodiment of the present invention 1 sees figure 1 .

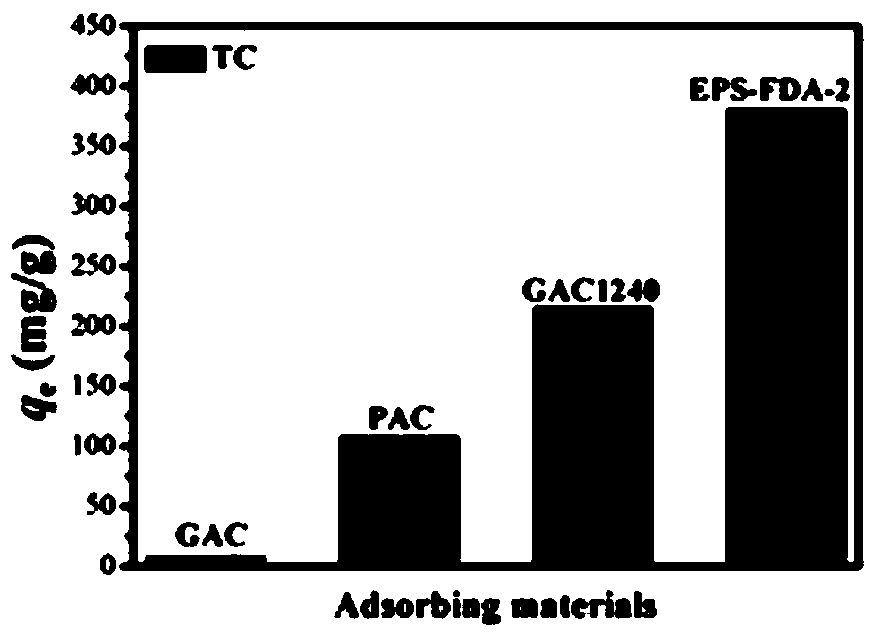

[0032] The comparison results of the adsorption properti...

Embodiment 2

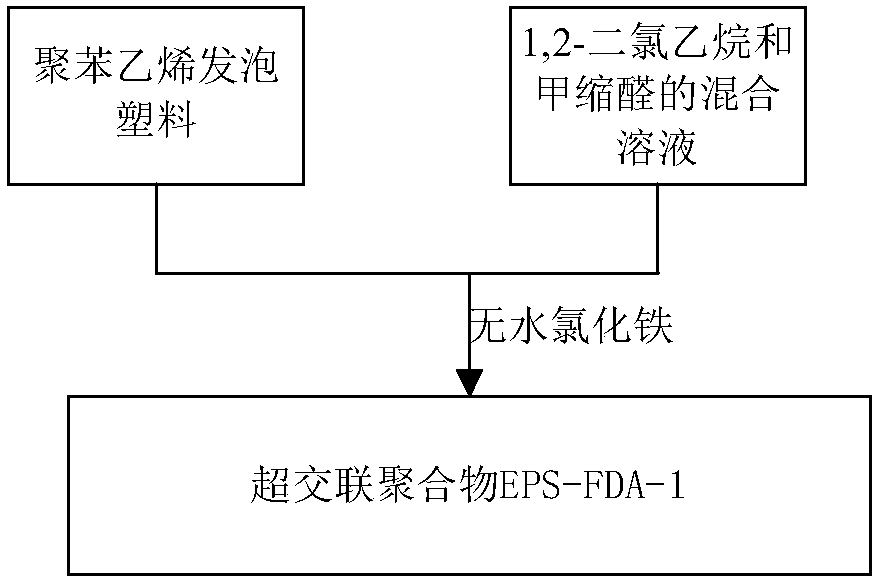

[0038] Weigh 0.5006g of expanded polystyrene (Expandable Polystyrene; EPS) and dissolve it in a mixed solution of 40mL of 1,2-dichloroethane and 5.6mL of methylal at room temperature, and then add 2.23g of anhydrous ferric chloride; The above system was subjected to cross-linking reaction at 80 °C for 12 h. After the reaction system was cooled to room temperature, it was washed 3 times with acetone, dilute hydrochloric acid and water respectively, then extracted with methanol for 24 h, and vacuum-dried for 12 h to obtain a hypercross-linked polymer. EPS-FDA-1.

[0039] The preparation process of the embodiment of the present invention 2 sees image 3 .

[0040] The specific surface area and pore size distribution parameters of the hypercrosslinked polymer EPS-FDA-2 prepared in Example 1 of the present invention and the hypercrosslinked polymer EPS-FDA-1 prepared in Example 2 are shown in Table 2.

[0041] Table 2: Specific surface area and pore size distribution parameters o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com