Wheat prolamin/nano-silver particles with green synthetic core-shell structure and its preparation method and application

A wheat gliadin and nano-silver particle technology, which is applied in the field of nano-material preparation, can solve the problems of easy aggregation and oxidation of silver nano-materials, and achieves enhanced food and biomedical applications, important social and economic benefits, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) carnosic acid is 95% ethanol solution with volume fraction, is made into the carnosic acid solution that mass concentration is 0.5%; Silver nitrate water is made into concentration and is 5 * 10 -2 mol / L silver nitrate solution;

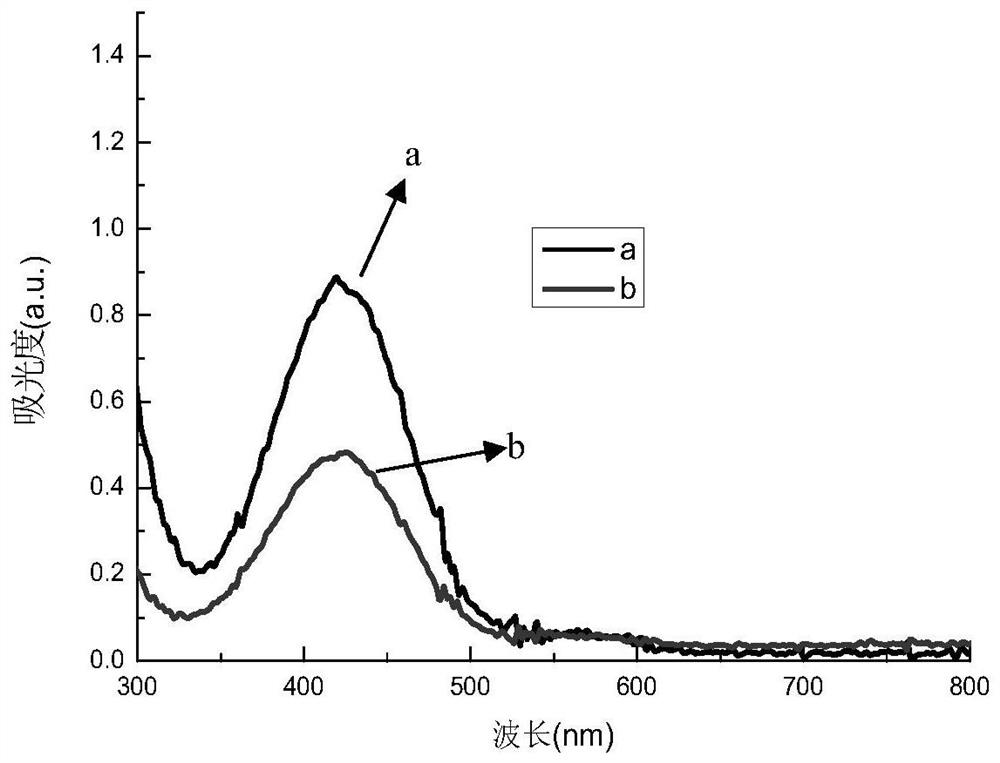

[0028] (2) 2mL mass concentration is 0.1% wheat prolamin solution (solvent is volume fraction is 70% ethanol solution) is added to 5mL concentration is 5 * 10 -2 mol / L silver nitrate solution in a constant temperature water bath for 10 minutes, then add 5 mL of carnosic acid solution with a mass concentration of 0.5% to the mixed solution, adjust the pH to 5.0 (adjusted with NaOH), and then heat in a constant temperature water bath at 37°C for 60 minutes , to prepare wheat prolamin / nano-silver particles with core-shell structure. After determination, the ultraviolet-visible spectrum of gained product is as figure 1 shown.

[0029] Ultraviolet-visible spectrum is an important index to characterize the synthesis and stability of wheat pro...

Embodiment 2

[0037] (1) carnosic acid is 95% ethanol solution with volume fraction, is made into the carnosic acid solution that mass concentration is 0.5%; Silver nitrate is made into concentration with distilled water and is 5 * 10 -2 mol / L silver nitrate solution;

[0038] (2) 2mL mass concentration is 0.5% wheat prolamin solution (solvent is volume fraction is 70% ethanol solution) is added to 5mL concentration is 5 * 10 -2 mol / L silver nitrate solution in a constant temperature water bath for 10 minutes, then add 5 mL of carnosic acid solution with a mass concentration of 0.5% to the mixed solution, adjust the pH to 5.0 (adjusted with NaOH), and then heat in a constant temperature water bath at 37°C for 60 minutes , to prepare wheat prolamin / nano-silver particles with core-shell structure.

[0039] After measuring, the ultraviolet-visible spectrogram of gained product is as follows figure 1 shown. The wheat prolamin / nano-silver of this embodiment has good stability, high yield and go...

Embodiment 3

[0041] (1) carnosic acid is 95% ethanol solution with volume fraction, is made into the carnosic acid solution that mass concentration is 0.5%; Silver nitrate is made into concentration with distilled water and is 5 * 10 -2 mol / L silver nitrate solution;

[0042] (2) 8mL mass concentration is 0.1% wheat prolamin solution (solvent is that volume fraction is 70% ethanol solution) is added to 5mL concentration and is 5 * 10 -2 mol / L silver nitrate solution in a constant temperature water bath for 10 minutes, then add 5 mL of carnosic acid solution with a mass concentration of 0.5% to the mixed solution, adjust the pH to 5.0 (adjusted with NaOH), and then heat in a constant temperature water bath at 37°C for 60 minutes , to prepare wheat prolamin / nano-silver particles with core-shell structure.

[0043] After measuring, the ultraviolet-visible spectrum of gained product Figure 4 shown. The wheat prolamin / nano-silver of this embodiment has good stability, high yield and good an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com