Method for secondary aluminum ash recycling

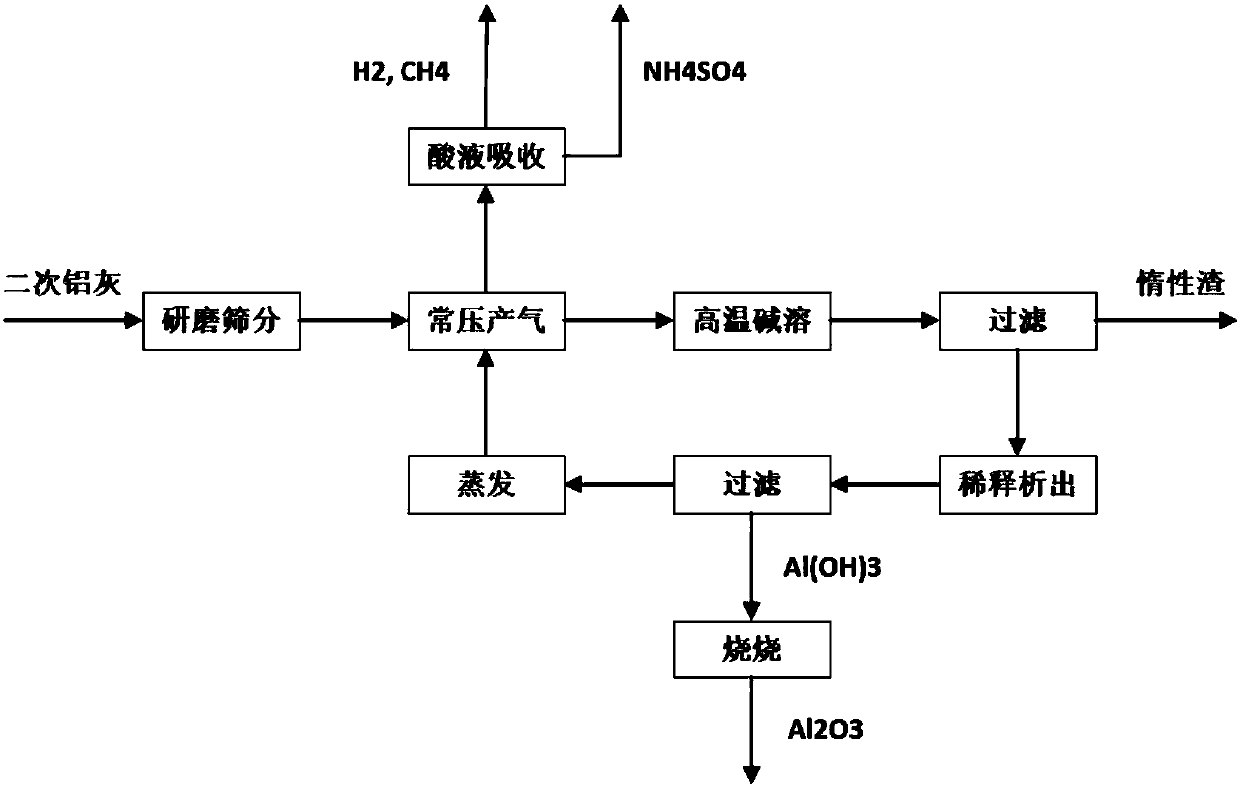

A secondary aluminum and resource-based technology, applied in the field of resources and environment, can solve the problems of inability to extract, accumulate and occupy, pollute the environment, etc., achieve high practical value, reduce operating costs and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The secondary aluminum ash is ground and passed through a 10-mesh sieve; add 15% caustic soda (NaOH) solution to it according to 15% sieved material and 1% anti-boiling agent (the mass ratio of activated carbon and porous synthetic phenolic resin is 1:2) , fully react under normal pressure, the elemental aluminum in the aluminum ash reacts with caustic soda to produce hydrogen (H 2 ), elemental aluminum is oxidized into sodium metaaluminate, and aluminum carbide and aluminum nitride in aluminum ash react with caustic soda to produce methane (CH 4 ) and ammonia (NH 3 ), under stirring conditions until no bubbles are seen, the ammonia gas becomes ammonium fertilizer after being absorbed by hydrochloric acid, and the remaining hydrogen and methane are collected, which can be used for system heating; type of alumina; filter the undissolved aluminum slag, and make bricks from the filter residue, and dilute the obtained filtrate to 1.5 times to increase the unsaturation of a...

Embodiment 2

[0031] The secondary aluminum ash is ground and passed through a 20-mesh sieve; add 20% caustic soda (NaOH) solution according to 25% of the sieved material and 3% of the anti-boiling agent (the mass ratio of activated carbon and porous synthetic phenolic resin is 2:2), Fully react under normal pressure, the elemental aluminum in the aluminum ash reacts with caustic soda to produce hydrogen (H 2 ), elemental aluminum is oxidized into sodium metaaluminate, and aluminum carbide and aluminum nitride in aluminum ash react with caustic soda to produce methane (CH 4 ) and ammonia (NH 3), under stirring conditions until no bubbles are seen, the ammonia gas becomes ammonium fertilizer after being absorbed by sulfuric acid, and the remaining hydrogen and methane are collected, which can be used for system heating; type of alumina; filter the undissolved aluminum slag, and make bricks from the filter residue, and dilute the obtained filtrate to 2.5 times to increase the unsaturation of...

Embodiment 3

[0033] The secondary aluminum ash is ground and passed through a 40-mesh sieve; add 25% caustic soda (NaOH) solution and 5% anti-boiling agent (the mass ratio of activated carbon and porous synthetic phenolic resin is 1:2) according to 35% of the sieved material, Fully react under normal pressure, the elemental aluminum in the aluminum ash reacts with caustic soda to produce hydrogen (H 2 ), elemental aluminum is oxidized into sodium metaaluminate, and aluminum carbide and aluminum nitride in aluminum ash react with caustic soda to produce methane (CH 4 ) and ammonia (NH 3 ), under stirring conditions until no bubbles are seen, ammonia gas becomes ammonium fertilizer after being absorbed by phosphoric acid, and the remaining hydrogen and methane are collected and can be used as energy materials for export; under 500°C high-pressure closed conditions, further stripping Alumina with insoluble crystal form; filter the undissolved aluminum slag, and use the obtained filter residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com