High-adaptability ester-based modified polycarboxylate superplasticizer as well as preparation and use methods thereof

An adaptable, polycarboxylic acid technology, applied in the field of building materials, can solve the problems of not meeting the requirements of green environmental protection production, large loss of slump over time, poor water reduction effect, etc., to achieve large-scale industrial production, adaptability Excellent, high water-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

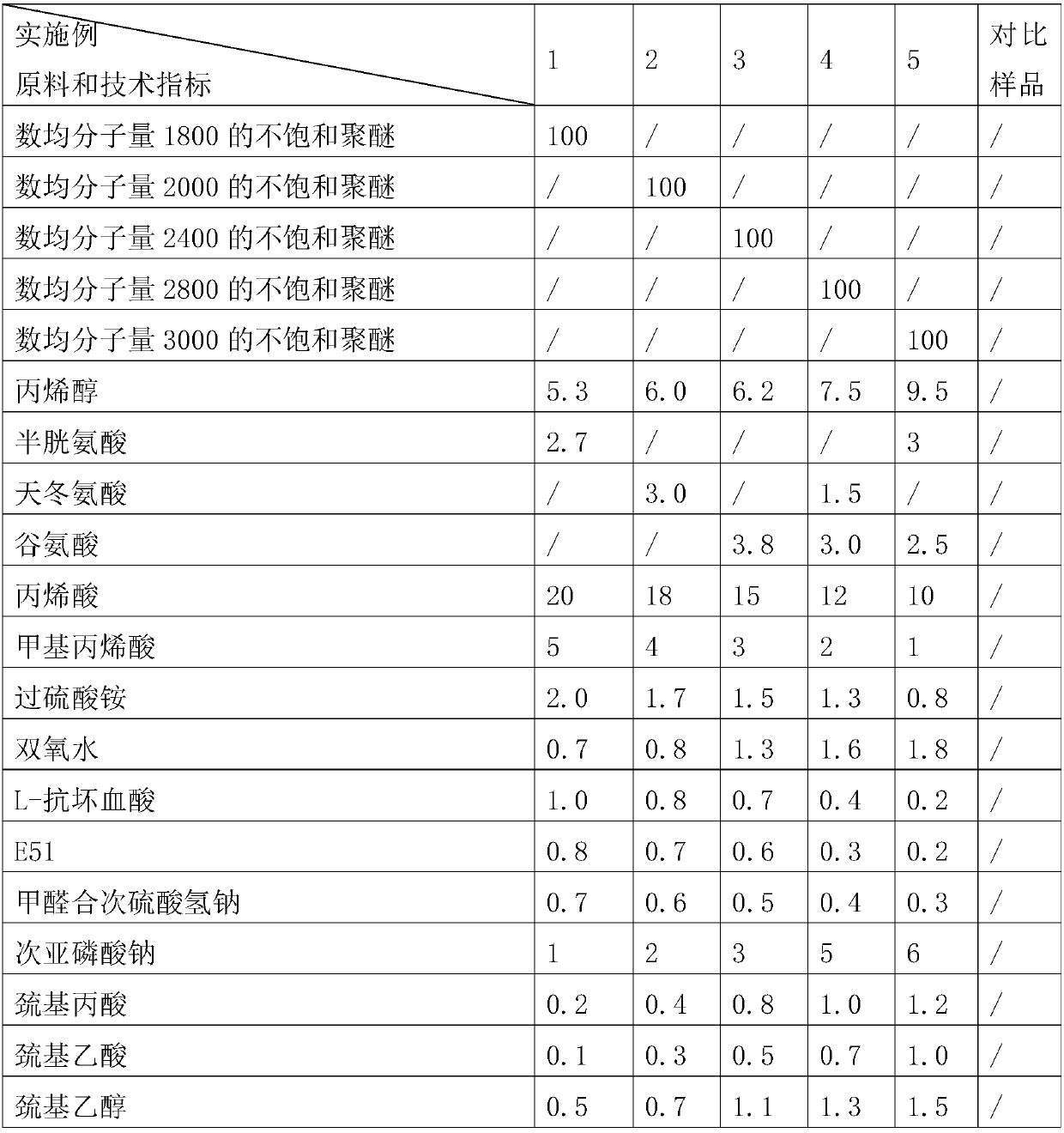

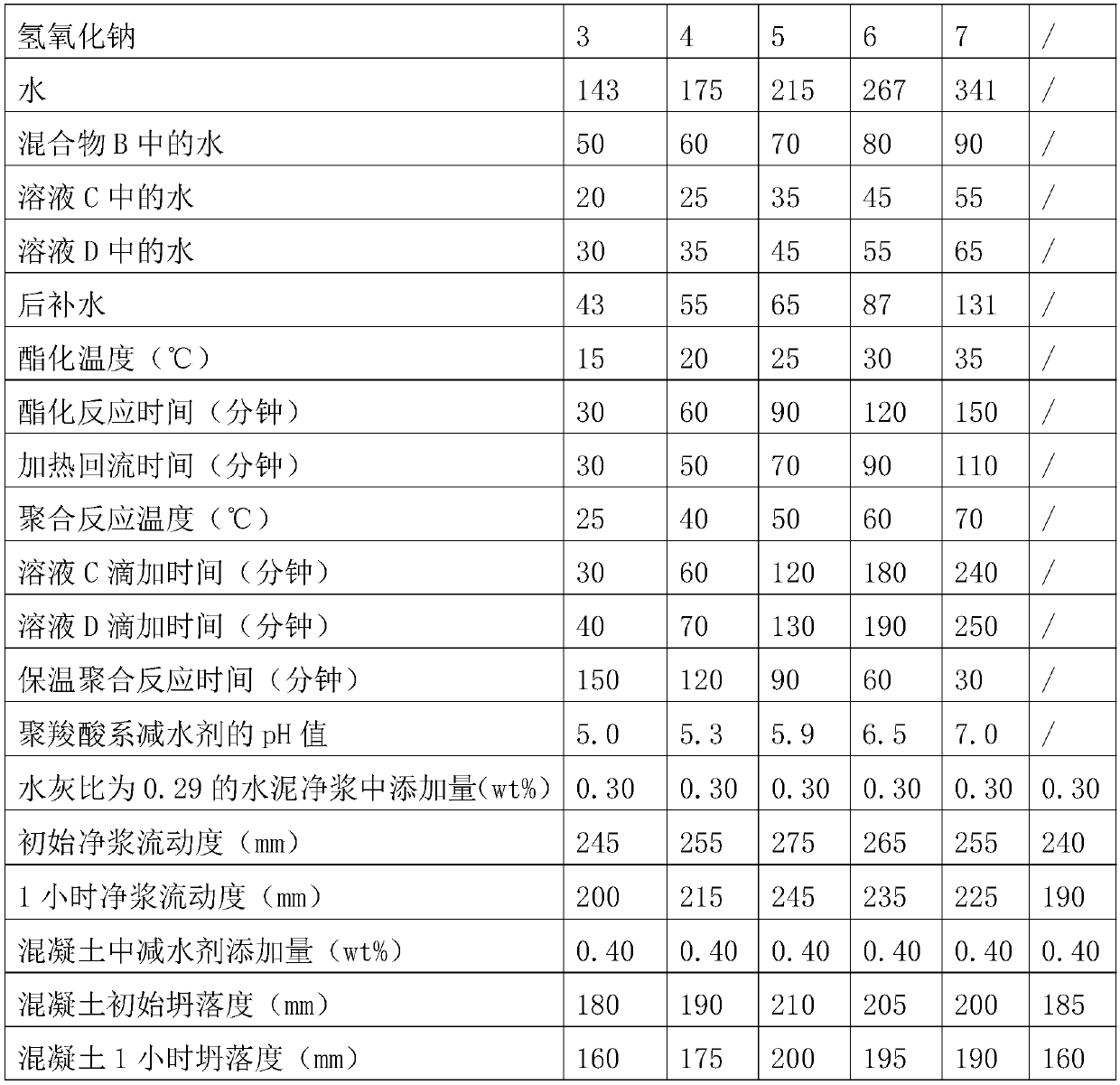

[0079] The present invention also provides a method for preparing the highly adaptable ester-modified polycarboxylate water reducer, which includes the following steps: under stirring conditions, in a flask with a reflux condenser, different polymerization temperatures Under the conditions, the HCL gas is continuously fed to carry out the esterification reaction of allyl alcohol and amino acid. After the reaction is completed, the water and excess allyl alcohol generated by the reaction are distilled off under reduced pressure, and the product is self-made functional ester A. Use self-made functional ester A to prepare highly adaptable ester-modified polycarboxylate water-reducer. The reaction is under stirring conditions. Hydrogen peroxide is added to mixture B, and then solution C and solution D are added dropwise to carry out polymerization reaction. After aging for a period of time, adjust it with water to a solid content of 30wt% to 50wt%, which is a highly adaptable ester...

Embodiment 1

[0108] (1) Preparation of functional ester A:

[0109] Preparation of functional ester A: Weigh 5.3 parts by weight of allyl alcohol and 2.7 parts by weight of cysteine, put them into a 500mL four-neck flask with a reflux condenser and mechanical stirring, and feed HCL gas at 15°C to react 30 minutes, heated to reflux for 30 minutes, decompressed distillation to remove the water and excess propenyl alcohol generated by the reaction, the resulting product is cysteine propenyl ester;

[0110] (2) Preparation before polymerization:

[0111] Preparation of mixture B: Weigh 100 parts by weight of isopentenol polyoxyethylene ether with a number-average molecular weight of 1800, 50 parts by weight of water, 1.0 parts by weight of sodium hypophosphite, and 0.7 parts by weight of hydrogen peroxide into a polymerization reactor, and stir evenly , keep at 25°C, reserve;

[0112] Preparation of solution C: Weigh 1.0 parts by weight of L-ascorbic acid, 0.8 parts by weight of E51, 0.7 p...

Embodiment 2~5

[0118] The preparation methods of Examples 2-5 are the same as those of Example 1, and the differences are specifically marked in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com